Defect and stress non-destructive testing system and non-destructive testing method based on pulsed eddy current and Barkhausen

A pulsed eddy current and non-destructive testing technology, applied in the direction of material magnetic variables, etc., can solve the problems of easy false detection, missed detection, low efficiency, cumbersome detection, etc., and achieve the effect of simple circuit, simple installation method and reliable detection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

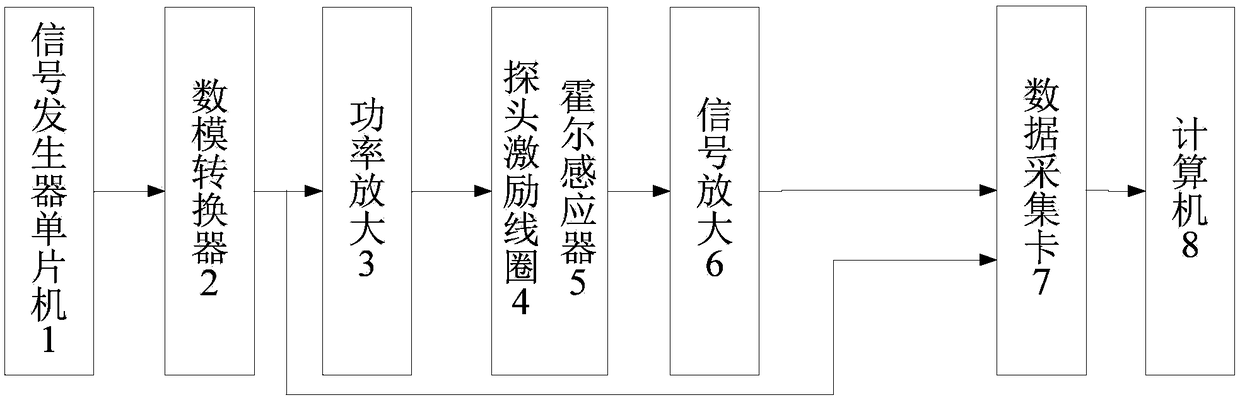

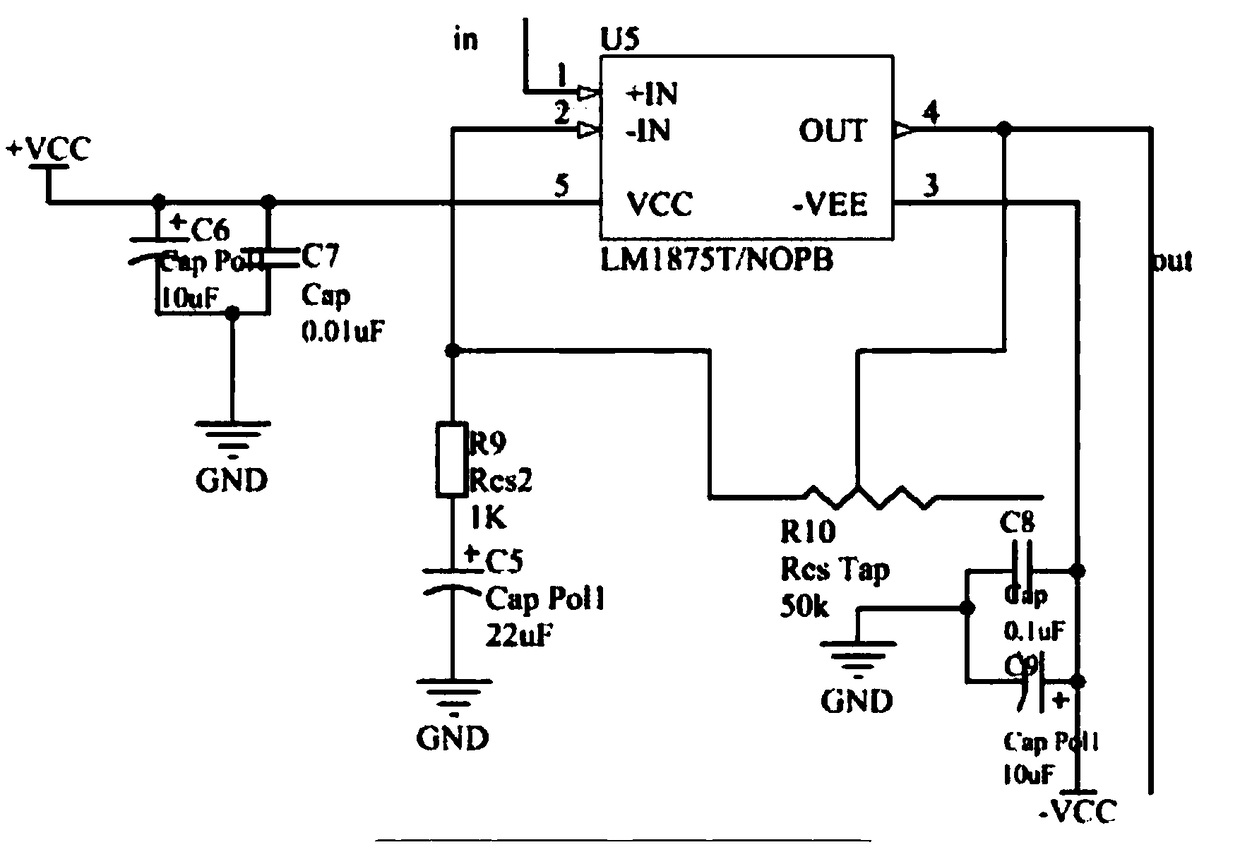

[0027] Such as figure 1 As shown, the nondestructive testing system of the present invention includes a signal generator single-chip microcomputer, digital-to-analog conversion, power amplifier, probe excitation coil, Hall sensor, signal amplification circuit, data acquisition card and computer; wherein the signal generator single-chip microcomputer is generated by program control Digital excitation signal. The digital excitation signal is a low-frequency mixed signal of rectangular wave and triangular wave. The frequency of the excitation signal can be changed by changing the parameters of the MCU program. Therefore, the frequency required for the excitation signal can be obtained by changing the program, and the MCU generates a digital excitation signal. Through the digital-to-analog converter, the digital signal is converted into an analo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com