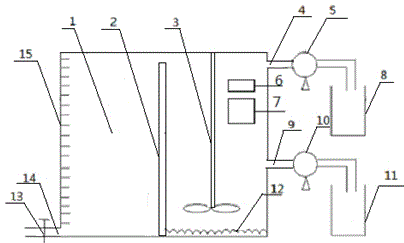

Lab-scale test equipment for oil separation tank

A small grease trap test and grease trap technology, applied in the direction of grease/oily substance/floating matter removal device, liquid separation, separation method, etc., can solve the problem of not being able to quickly find the best reagents and experimental conditions for separating different oily wastewater, Simple structure and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] like figure 1 As shown, close the wastewater outlet valve (13), and pump the oily wastewater in the wastewater pool (11) into the right side of the grease trap (1) through the wastewater inlet (9) through the wastewater pump (10). The medicine in the medicine pool (8) is pumped into the right side of the grease trap (1) through the medicine pump (5) through the medicine inlet (4). The power of the wastewater pump (10) and the medicament pump (5) is adjusted through the control panel (7) to control the wastewater flow rate and water flow rate, as well as the medicament flow rate and flow rate. Adjust the rotation speed of the agitator (3) through the control panel (7) to fully agitate the medicament and waste water, and control the electric heating network (12) to heat the mixture. When the waste water reaches a certain amount, it overflows the separation plate (2) and reaches the left side of the grease trap, and the timer (6) is used to calculate the standing time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com