Direct current motor control teaching experiment system

A technology of DC motors and experimental systems, applied in general control systems, control/adjustment systems, computer control, etc., can solve the problems of difficult establishment and verification of control experiments, complicated operations, etc., and achieve the effect of convenient remote control and teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

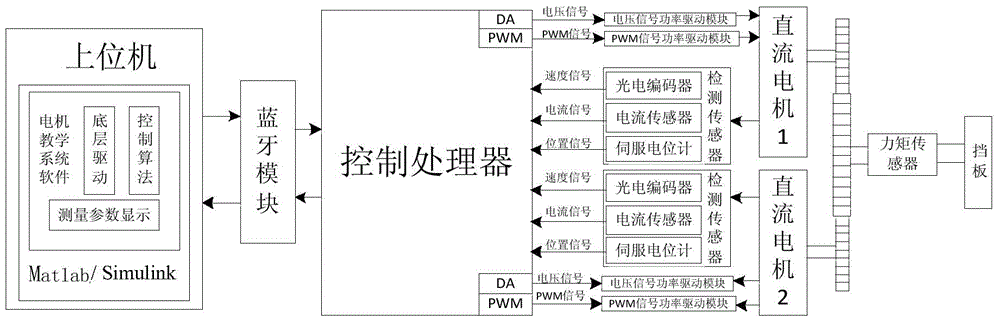

[0026] see figure 1 As shown, a kind of DC motor control teaching experiment system of the present invention comprises: upper computer, control processor and DC motor, described upper computer is downloaded to described control processor after automatically generating code by MATLAB / Simulink model-based design , the control processor transmits corresponding control signals to the DC motor, the DC motor is connected with a detection sensor, and the detection sensor returns the collected detection signal to the control processor, and the upper computer performs a detection signal on the detection signal Monitoring; the DC motor includes first and second DC motors connected to each other through a mechanical coupling transmission, and the mechanical coupling transmission is connected with a baffle plate for fixing its transmission shaft, on the transmission shaft of the mechanical coupling transmission A torque sensor connected to the control processor is installed.

[0027] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com