A magnetorheological damper with integrated energy recovery device

A technology of energy recovery device and magnetorheological damper, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., can solve the problems of insufficient excitation coil power supply, slow blade speed, etc., and reduce the overall structure size , the overall power consumption is small, and the effect of improving the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

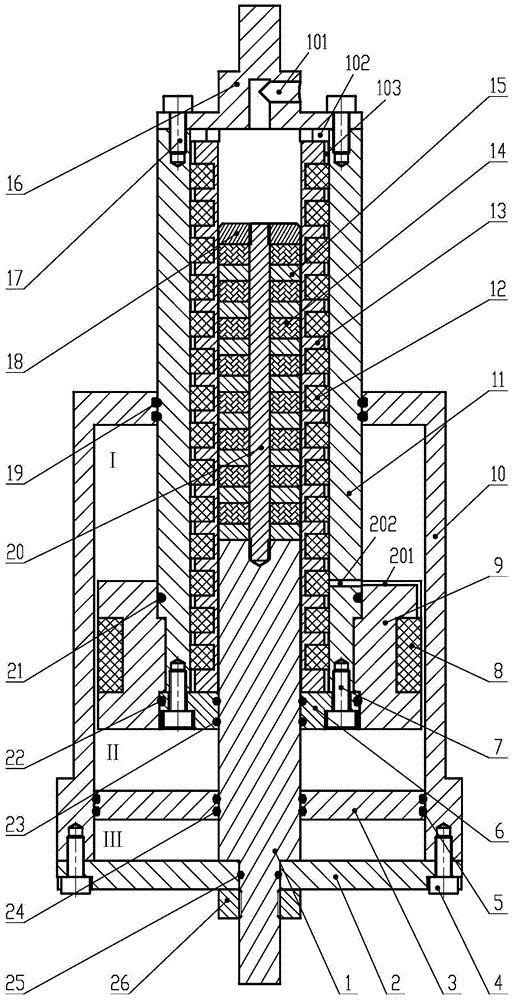

[0022] Such as figure 1As shown, the present invention includes a support rod 1, a lower end cover 2, a floating piston 3, a screw I4, a sealing ring I5, a baffle plate 6, a screw II7, an excitation coil 8, a piston 9, an outer sleeve 10, a piston rod 11, and an induction coil 12. Induction coil winding frame 13, permanent magnet 14, spacer 15, upper end cover 16, screw Ⅲ17, fastening sheet 18, sealing ring Ⅱ19, fastening pin 20, sealing ring Ⅲ21, sealing ring Ⅳ22, sealing ring Ⅴ23, Sealing ring VI24, sealing ring VII25 and lock nut 26.

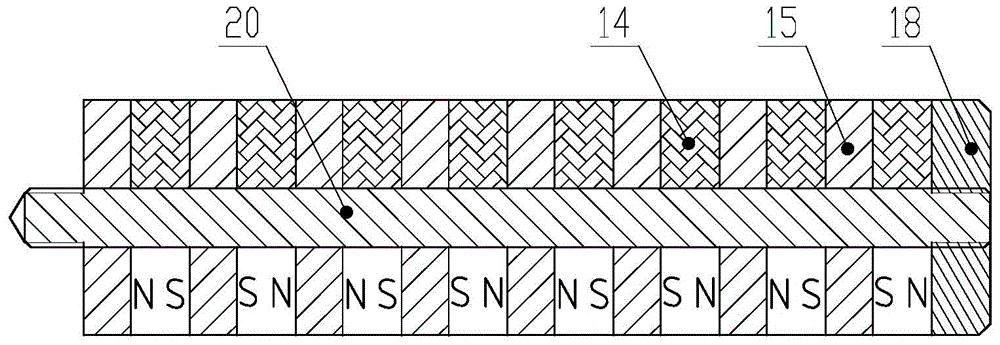

[0023] figure 2 Shown is a schematic diagram of the structural arrangement of the permanent magnet 14 and the spacer 15 of the present invention. The permanent magnets 14 are arranged in a structure in which N poles-N poles face each other, and S poles-S poles face each other. Two permanent magnets 14 are separated by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com