Needle-pressing mechanism for warp-knitting machine

A technology of warp knitting machine and motion mechanism, which is applied in warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of shortening the service life of jacquard pressing needle components, easy wear of grooves by push needles, and reducing the quality of loop knitting, etc. problem, achieve the effect of avoiding injection or missing needle accident, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

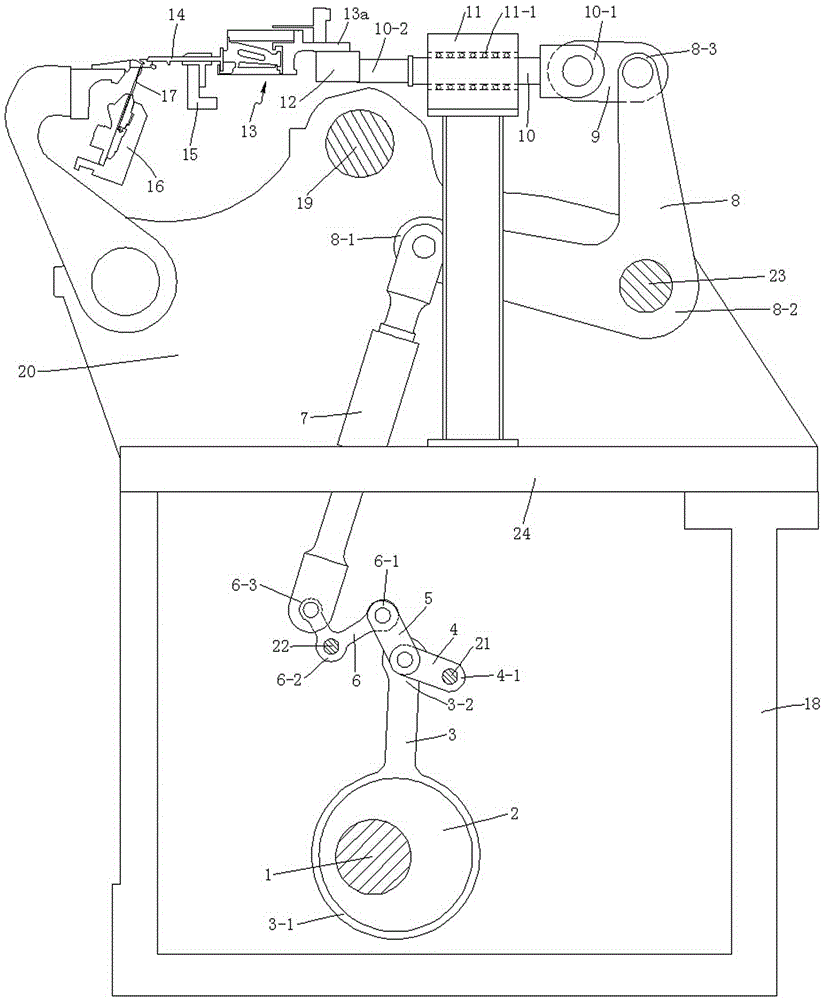

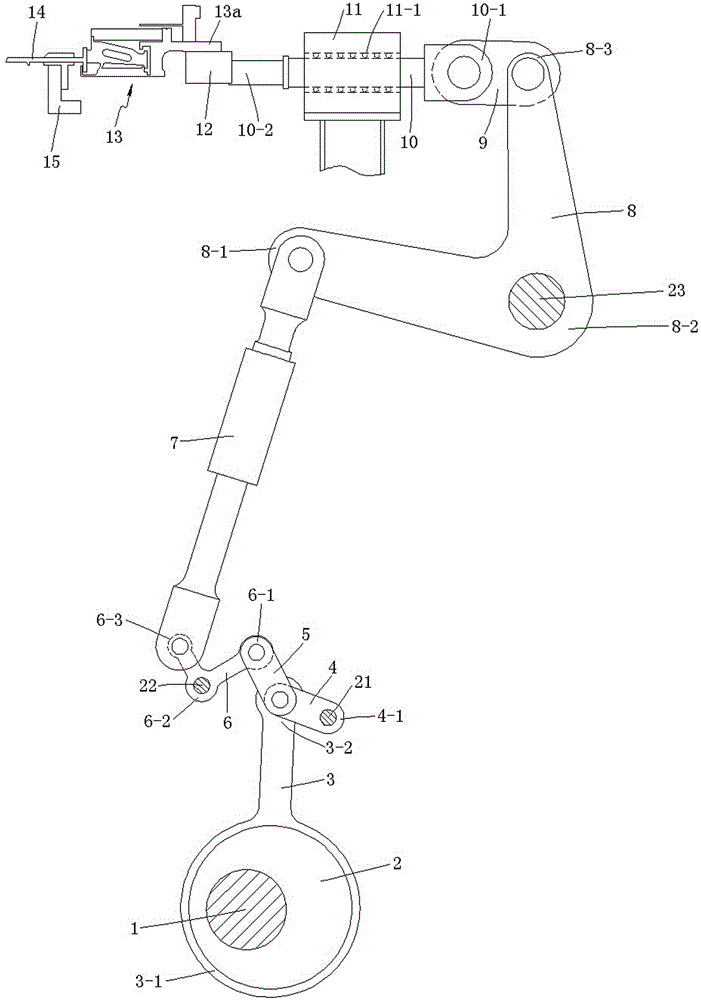

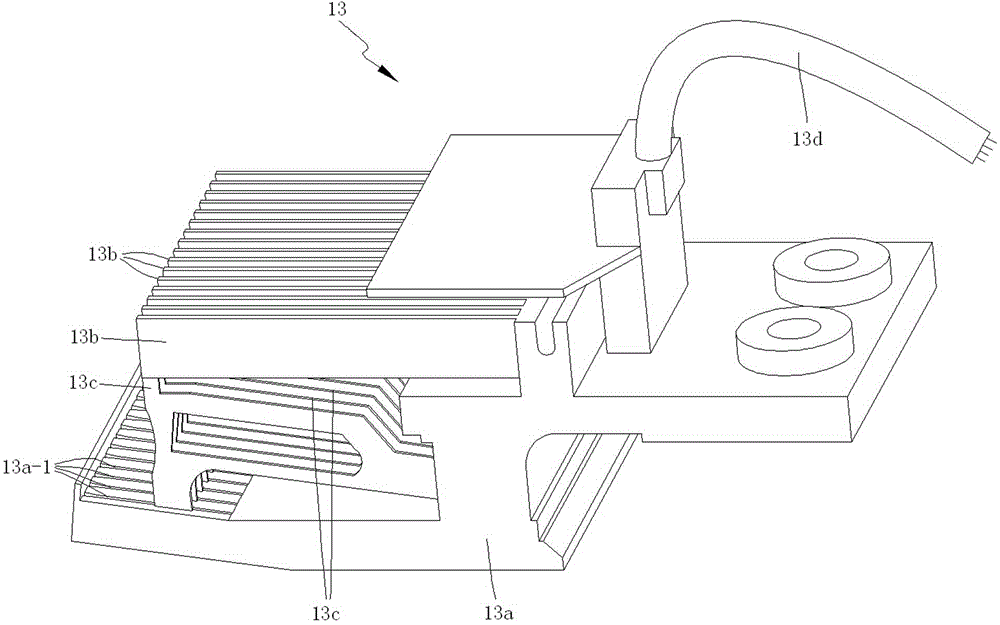

[0016] see Figure 1 to Figure 4 The shown needle pressing mechanism of a kind of warp knitting machine comprises a transmission main shaft 1 which is rotatably installed in the oil tank 18 of the warp knitting machine through a bearing, a jacquard needle bed 12, a jacquard needle pressing assembly 13, and a push needle 14 for The push needle guide block 15 that is guided when the push needle 14 moves, and the crochet needle 17 that is fixedly installed on the crochet bed 16 by the pressing plate; 13b, a push pin piece 13c and a wire 13d, the piezoelectric ceramic pieces 13b are fixedly installed on the base 13a in parallel at a certain distance from each other such as 2 or 3mm, and each piezoelectric ceramic piece 13b is connected to the wire respectively. 13d, the wire 13d usually adopts a cable with multiple joints, and each joint corresponds to a piezoelectric ceramic sheet 13b connected to a power source, so that the corresponding piezoelectric ceramic sheet 13b is energi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com