A kind of anodized aluminum chromatographic dye containing hyperbranched polymer and preparation method thereof

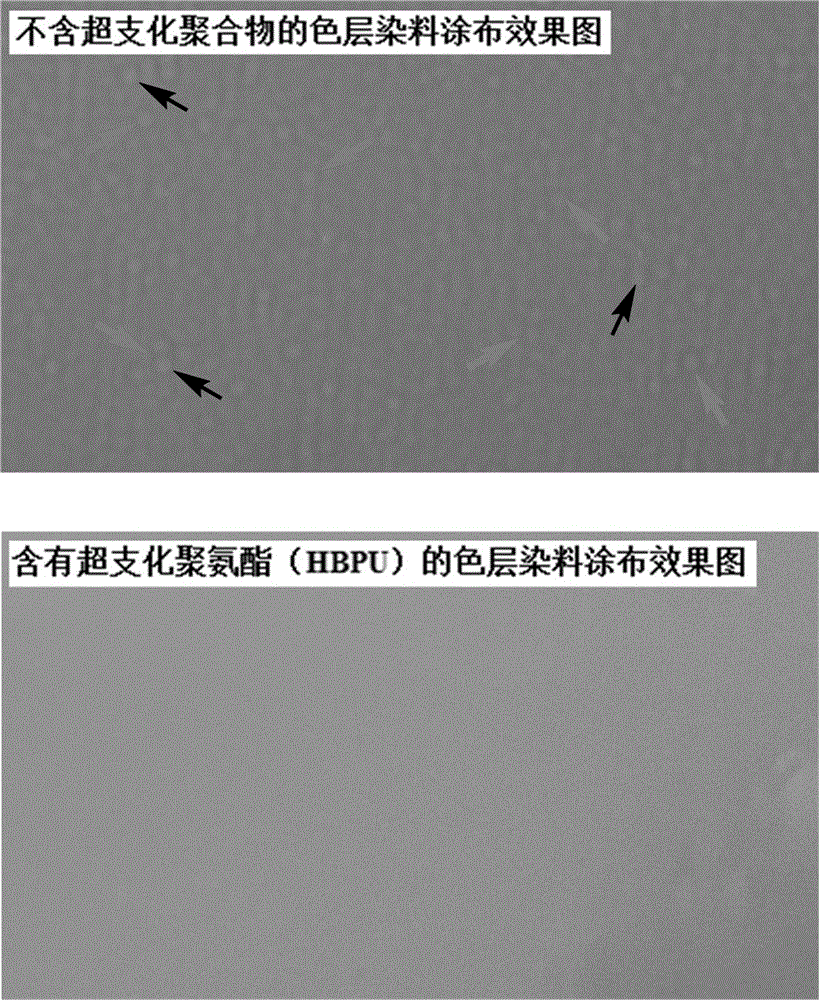

A technology of hyperbranched polymers and hyperbranched polyurethanes, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as high viscosity, incompatibility between color layer resin and dye toner, association and settlement, and achieve low Viscosity, the effect of excellent solubility properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Put 63kgEA and 7kgMIBK into the reaction kettle first, keep the temperature in the kettle at 30°C; put 15kg Cr at one time 3 [Fe(CNS) 6 ], 5kg HBPU, 0.4kg polyacrylic acid, and 0.4kg polypropylene wax were put into the kettle, stirred for 2 h, and the stirring rate was 300 r / min; sequentially added 30kg hydroxymethyl methacrylate, 25kg polyether polyurethane and 3kg perchlorethylene Resin, adjust the temperature to 40°C, stir for 4 hours, and stir at a rate of 500 r / min; finally, the uniformly mixed material flows into the storage tank through the kettle body device for standby, and the internal temperature of the storage tank is 30°C.

Embodiment 2

[0048] Put 60kgEA into the reaction kettle first, keep the temperature in the kettle at 25°C; put 7kg K 3 [FeF 6 ], 1kg HBPU, 0.5kg polyacrylic acid were put into the kettle, stirred for 1 h, and the stirring rate was 100 r / min; 20kg hydroxymethyl methacrylate, 20kg polyether polyurethane and 1kg perchlorethylene resin were added in sequence, and the temperature was adjusted to 15°C , Stir for 2 h, and the stirring rate is 200 r / min; finally, the uniformly mixed material flows into the storage tank through the kettle body device for standby, and the internal temperature of the storage tank is 10°C.

Embodiment 3

[0050] Put 80kg MIBK into the reaction kettle first, keep the temperature in the kettle at 60°C; put 20kg Co(NO 2 ) 3 (NH 3 ) 3 , 10kg HBPU, 1.0kg polypropylene wax were put into the kettle, stirred for 4 h, and the stirring rate was 500 r / min; 40kg hydroxymethyl methacrylate, 40kg polyether polyurethane and 5kg perchlorethylene resin were added in sequence, and the temperature was adjusted to 70°C , Stir for 6 h, and the stirring rate is 700 r / min; finally, the uniformly mixed material flows into the storage tank through the kettle body device for standby, and the internal temperature of the storage tank is 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com