D-column structure for automobile and D-column structure manufacturing method

A column structure, automobile technology, applied in the direction of superstructure, sub-assembly of superstructure, vehicle parts, etc., can solve the problems such as the difficulty in realizing the welding spot of the body frame, the difficulty in stamping and forming of parts, and the low rigidity mode of the body, so as to achieve the improvement Body performance, improved work efficiency, effects of improved stiffness and modal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

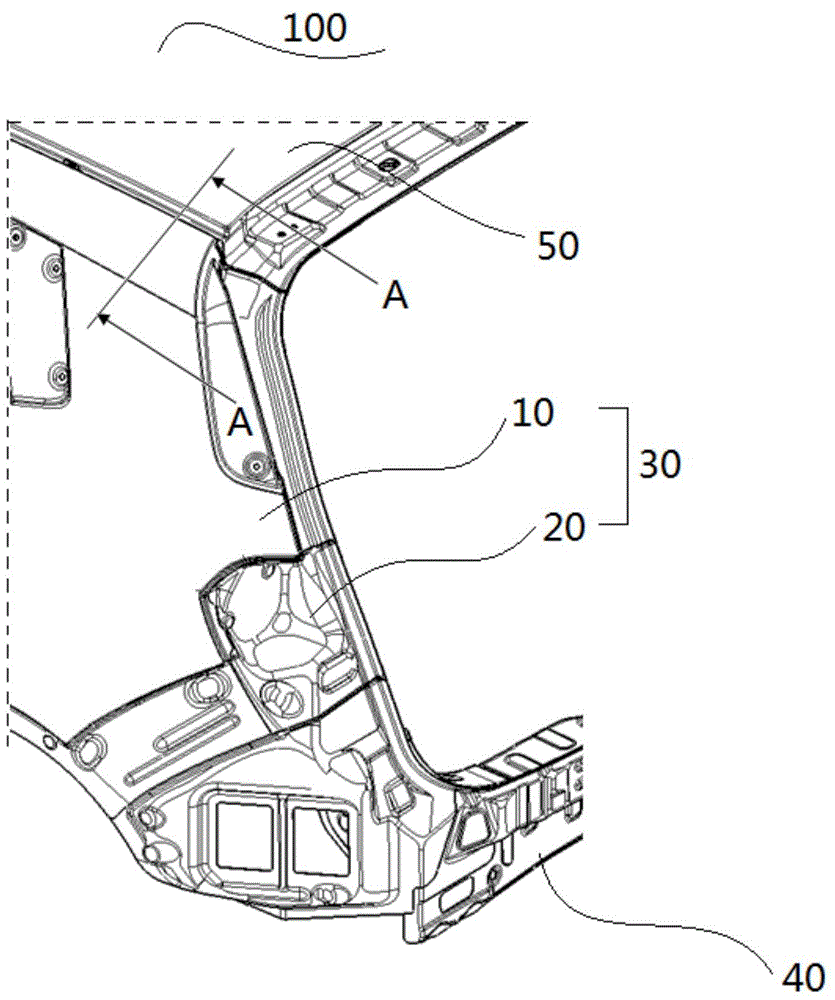

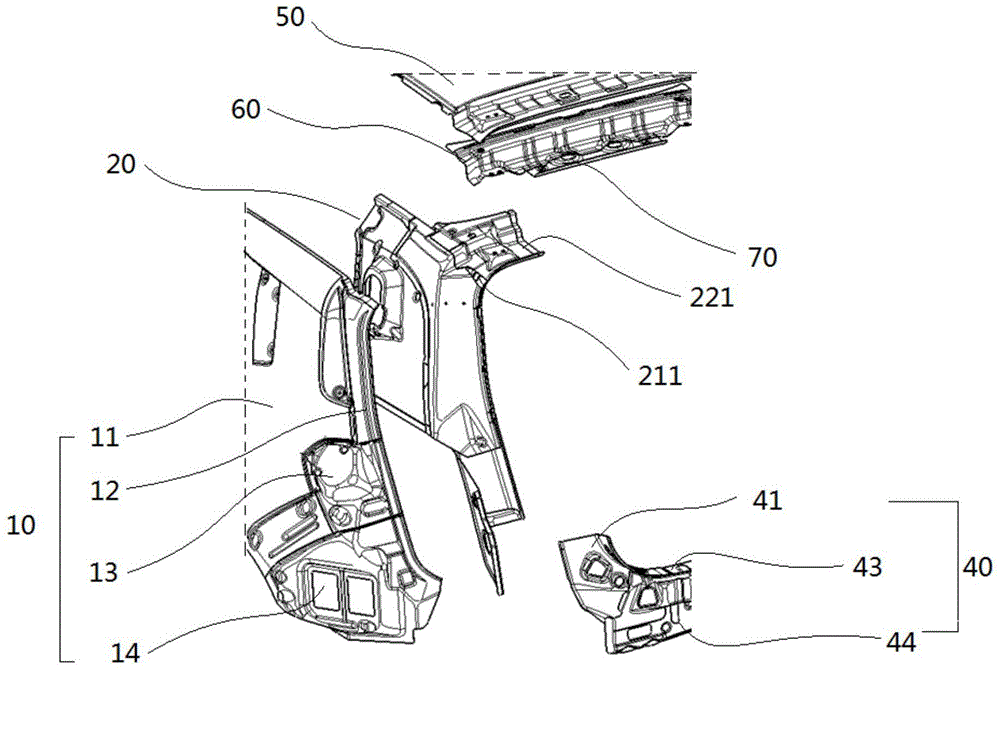

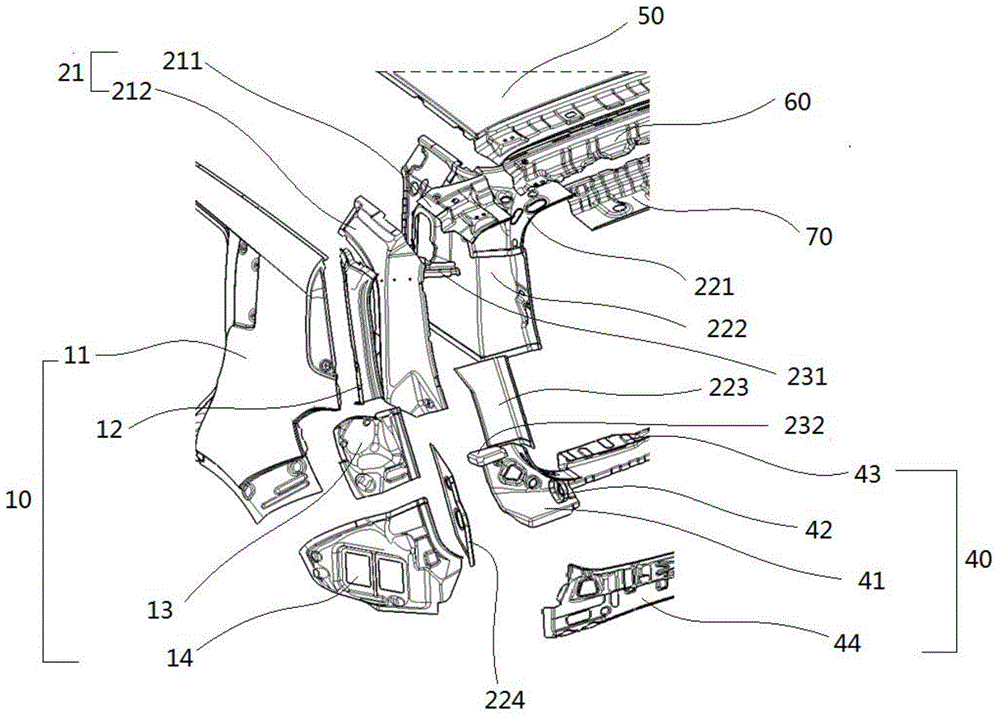

[0048] see figure 1 , which shows a D-pillar structure 100 for an automobile according to an embodiment of the present invention. combine figure 2 As shown, the D-pillar structure 100 includes a side panel assembly 30 , an underbody assembly 40 , a roof outer panel 50 , a rear roof cross member reinforcement panel 60 and a rear roof cross member inner panel 70 . The upper end of the side wall assembly 30 , the roof outer panel 50 , the rear roof beam reinforcement plate 60 and the rear roof beam inner panel 70 are fixedly connected to each other, and the lower end of the side wall assembly 30 is fixedly connected to the lower body assembly 40 . Specifically, such as figure 2As shown, the side wall assembly 30 includes a side wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com