Integrated unequal-length double-wishbone suspension wheel drive system to reduce unsprung mass

An unsprung mass and wheel-side drive technology, which is applied in the direction of suspension, elastic suspension, motion deposition, etc., can solve the problems of difficult steering, the installation of reduction gear and the distribution of mass are not well unified, and achieve Effects of improving layout and unsprung mass issues, reducing unsprung mass, and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

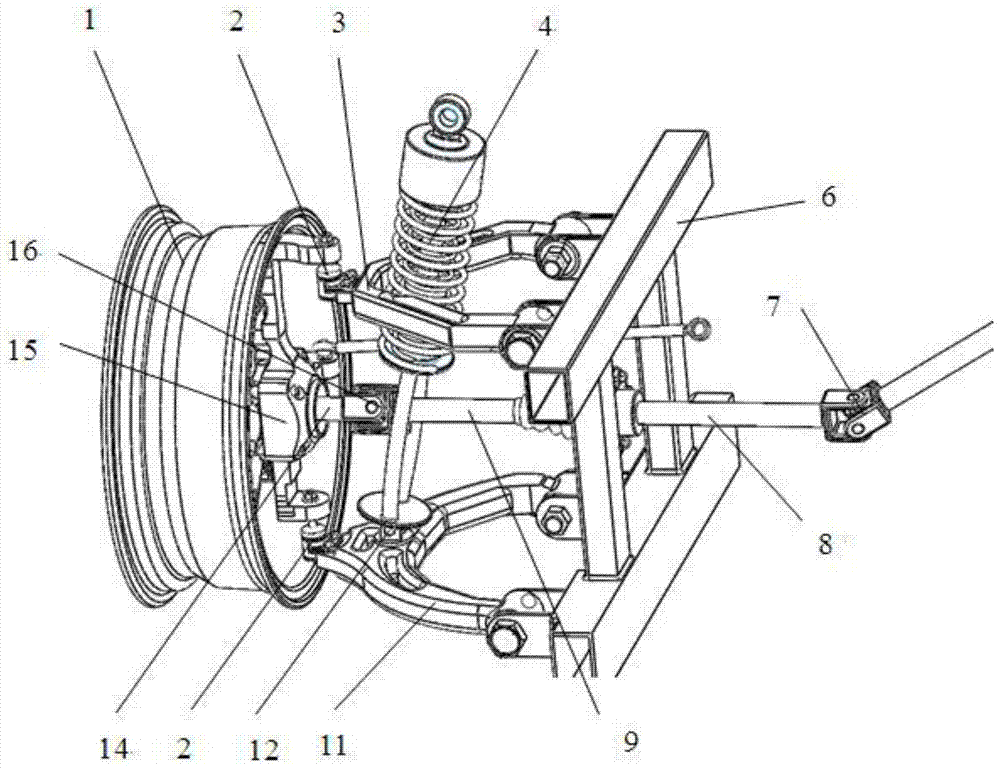

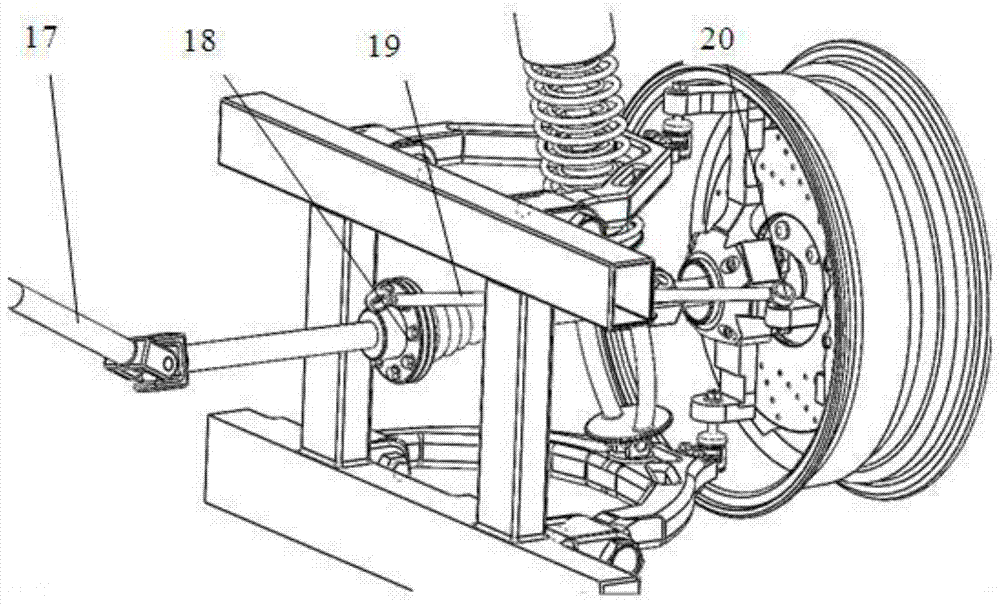

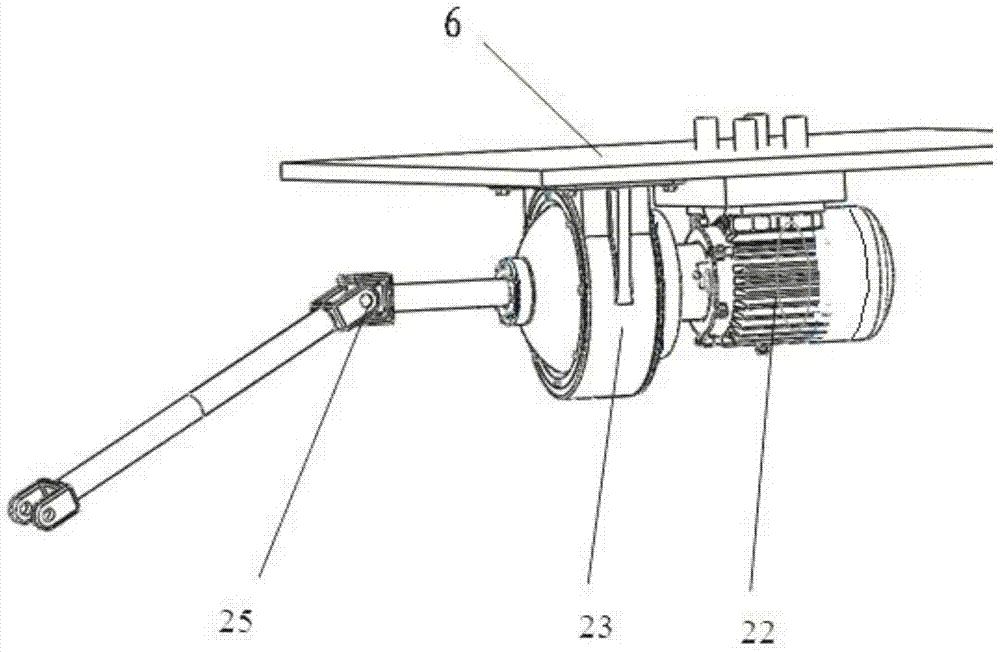

[0024] Such as figure 1 , 2 Shown in and 4 is an integrated unequal-length double-wishbone suspension wheel-side drive system that reduces unsprung mass, including a vehicle frame 6, an integrated drive device, a No. 2 cross cardan coupling 25, a universal Joint transmission shaft 17, No. 1 cross universal joint coupling 7, transmission shaft 8, disc coupling 18, wheel transmission shaft 9, ball cage type constant velocity universal joint 16 and wheel hub 1, the drive integration The device is set with the frame 6, and the shaft system of the drive integration device is connected with the universal joint transmission shaft 17 through the No. 2 cross universal joint coupling 25, and the universal joint transmission shaft 17 is connected with the The joint shaft coupling 7 is connected with the transmission shaft 8, and the transmission shaft 8 is connected with the wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com