Vacuum injection molding die

A vacuum injection molding and mold technology, which is applied in the field of molds, can solve problems such as uneven product shape, uneven force of demolding components, and strain on thin product positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

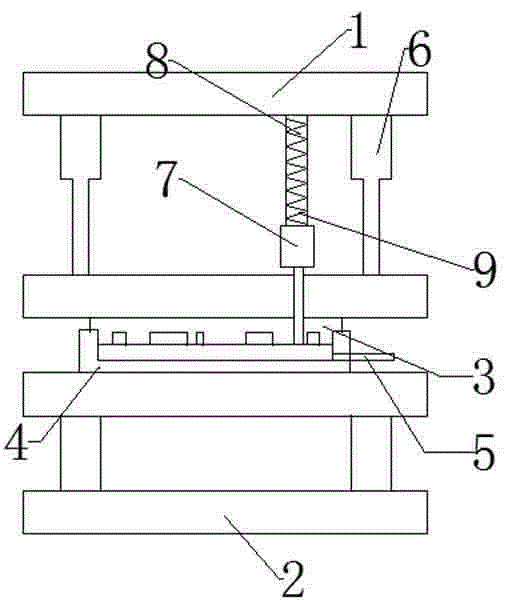

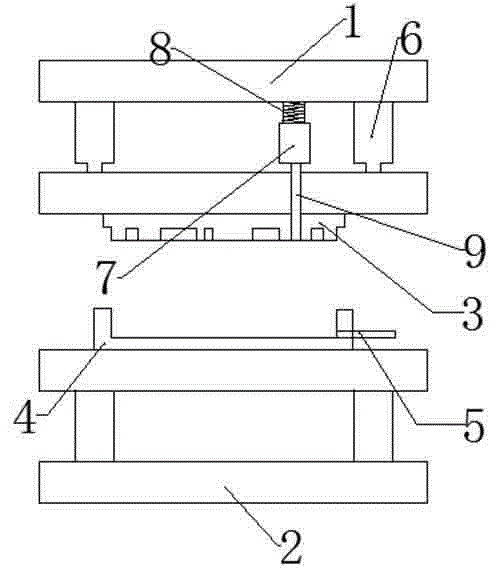

[0017] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0018] The vacuum injection mold includes: an upper mold base 1, a lower mold base 2, an upper template 3 under the upper mold base 1, a lower template 4 fixed on the lower mold base 2, and a connection between the upper mold base 1 and the upper mold base 3 The telescopic part between them, as for the material injection port 5 on the lower formwork 4, is connected to the suction and blowing assembly of the upper formwork 3; as a preference, the telescopic part is an electric telescopic rod 6. Vacuum the molding tank before injection molding, which not only facilitates the entry of materials into the molding tank, but also prevents air bubbles or uneven product shapes due to air pressure when the product is molded. The molding groove is opened from the inside out, and the demoulding is clean and neat.

[0019] The suction and blowing ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com