Waste gas purification apparatus

A technology of exhaust gas purification device and air intake device, which is applied in the direction of combination device, chemical instrument and method, and separation of dispersed particles, which can solve the problems of inability to collect dust, flow out of dust, and pollute the environment, so as to reduce workload and prolong service life , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] specific implementation plan

[0035] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

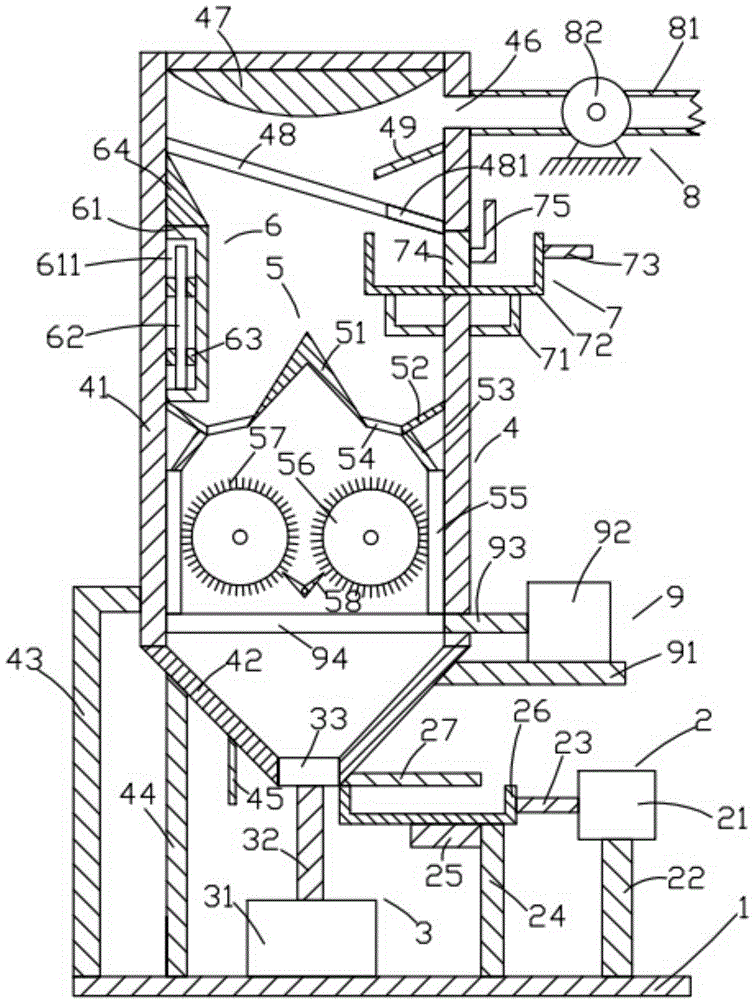

[0036] like figure 1As shown, the exhaust gas purification device proposed by the present invention includes a base 1, a first dust collecting device 2 located above the base 1, a cylinder device 3 located on the left side of the first dust collecting device 2, and a cylinder device 3 located on the left side of the cylinder device 3. The upper frame device 4, the heating device 6 located inside the frame device 4, the first filter device 5 located below the heating device 6, and the second dust collection device 7 arranged on the frame device 4 , the air intake device 8 located on the right side of the frame device 4 and the second filter device 9 arranged below the frame device 4 .

[0037] like figure 1 As shown, the base 1 is in the shape of a cuboid, and the base 1 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com