Automatic electrical control cabinet

A technology of electrical control cabinets and controllers, applied in the field of control cabinets, can solve the problem that electrical control cabinets cannot meet mass production and automatic production, cannot effectively utilize the production efficiency and production quality of control cabinets, and cannot set feeding materials for electrical control cabinets The length and feeding speed and other issues can be shortened to shorten the time for adjusting and testing the feeding distance, the structure is novel, and the effect of avoiding industrial accidents is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

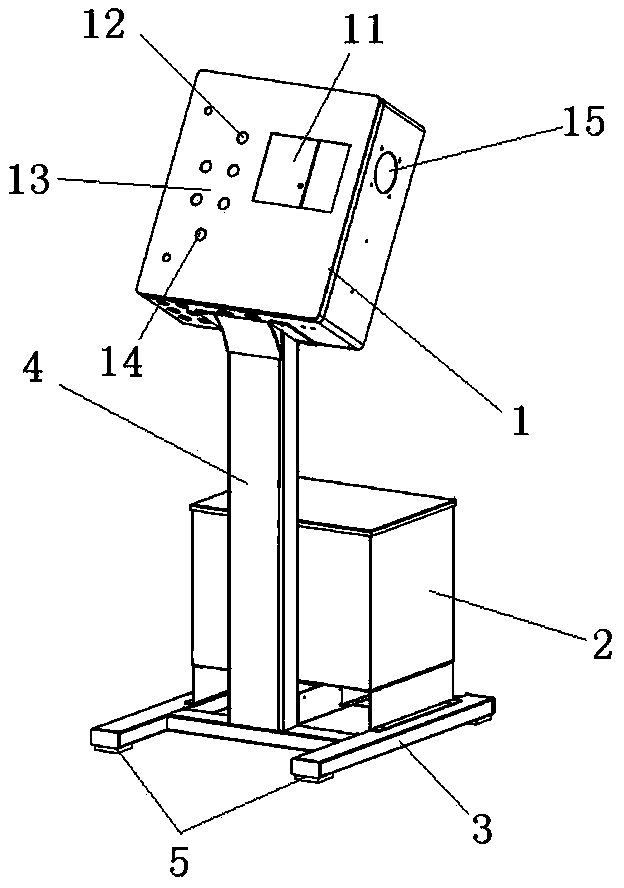

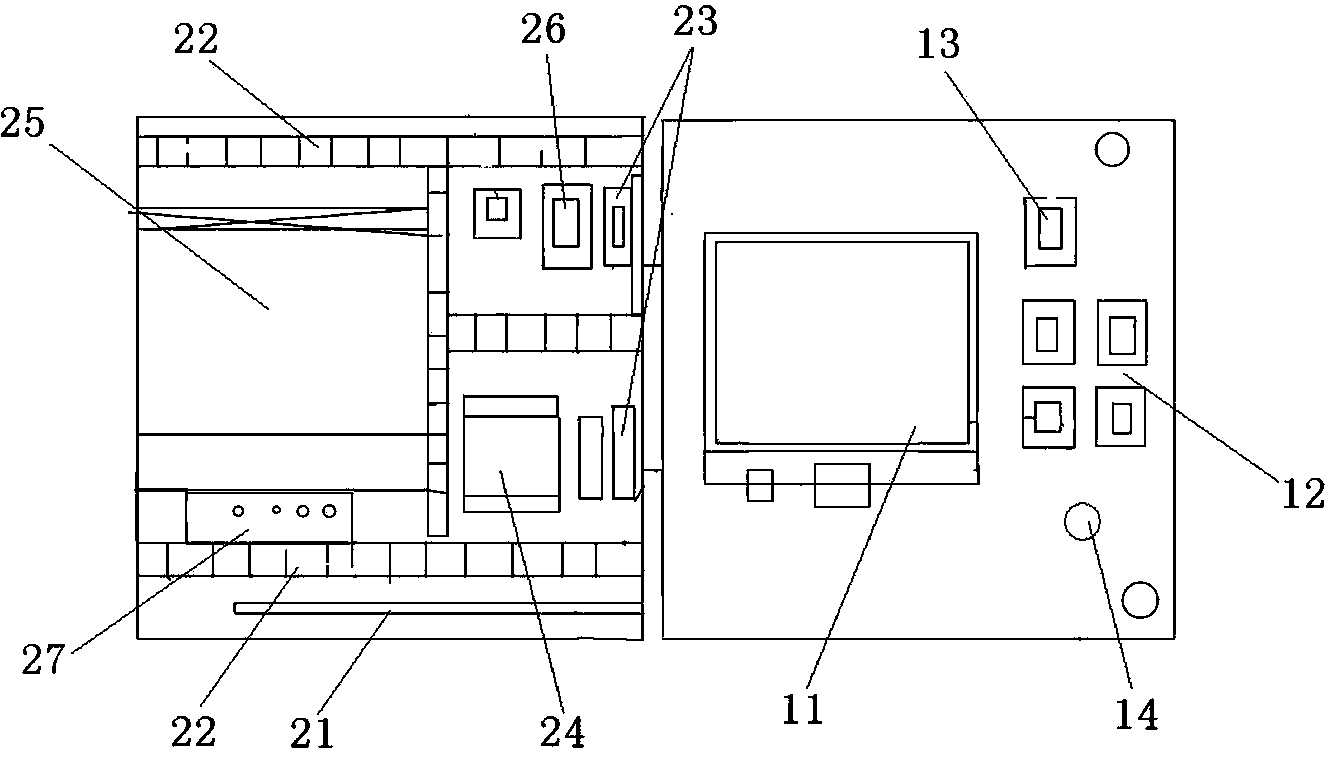

[0017] figure 1 It shows an embodiment of an automated electrical control cabinet of the present invention, comprising an upper cabinet 1, a lower cabinet 2, a bracket 3 and a support column 4, the lower cabinet 2 is arranged on the bracket 3, and the support The bottom of the column 4 is connected to the lower cabinet body 2, and the top of the support column 4 is connected to the upper cabinet body 1. The upper cabinet body 1 is inclined at an angle of 20-45 degrees. The control panel of the upper cabinet body 1 is provided with a touch control panel 11 , a control button 12, a power switch 13 and a control cabinet lock 14; the upper cabinet is provided with a terminal block 21, a trunking 22, a relay 23, a controller 24, a servo driver 25, a safety device 26 and a power supply 27; There is a transformer inside the cabinet 2; the side of the upper cabinet 1 is provided with a cooling fan 15 installed at the air outlet; At the bottom of the cabinet 1, a relay 23, a controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com