Aerospace specific food cooking and kitchen smoke purifying system

A purification system and kitchen smoke technology, which is applied in applications, household stoves, household heating, etc., can solve the problems of aerospace food diversity restrictions, etc., and achieve strong smoke removal effects and strong purification capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

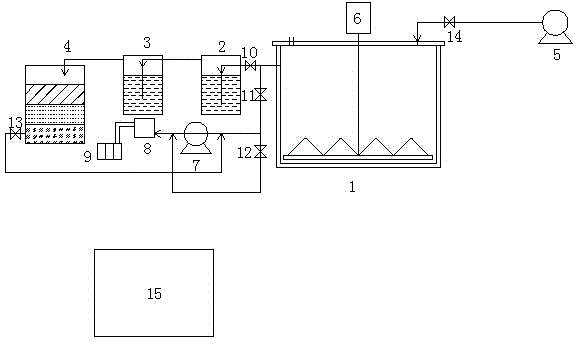

[0016] Specific implementation mode one: as figure 1 As shown, the aerospace-specific food cooking and kitchen fume purification system provided in this embodiment is composed of a cooking device, a smoke removal system and a pressure pump 5, wherein:

[0017] Described cooking device comprises cooking pot 1, stirrer 5, heater, and cooking pot 1 top is fixedly connected stirrer 6, and the transmission shaft of stirrer 6 stretches into inner cavity from cooking pot 1 upper end and is flexibly connected with cooking pot 1 upper surface, A stirring paddle is arranged at the bottom of the transmission shaft, and a heater is installed at the bottom of the cooking kettle 1;

[0018] The smoke removal system includes a smoke cooling buffer 2, a kitchen smoke purifier 3, a purified gas compressor collector 4, a vacuum pump 7, a steam generator 8, and a storage battery 9. The smoke outlet of the cooking kettle passes through an electronically controlled valve F 8 10 is connected with...

specific Embodiment approach 2

[0029] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step (1), the radius of the cross-section of the cylinder of the smoke cooling buffer 2 is 50-80 cm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one is: step (2) the adsorption liquid in the kitchen smoke purifier 3 The anionic surfactant in the adsorption liquid is sodium alkyl sulfonate, alkyl aryl Any one of sodium sulfonate and sodium alkyl sulfate, and the nonionic surfactant is any one of polyoxyethylene fatty alcohol ether and polyoxyethylene alkylphenol ether. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com