Preparation method of natural milk-flavored base material

A milk-based, natural technology, applied in food preparation, dough processing, baking, etc., can solve the problems of high acid value, thin taste, etc., and achieve good taste, good heat resistance and fragrance, milk Fragrant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

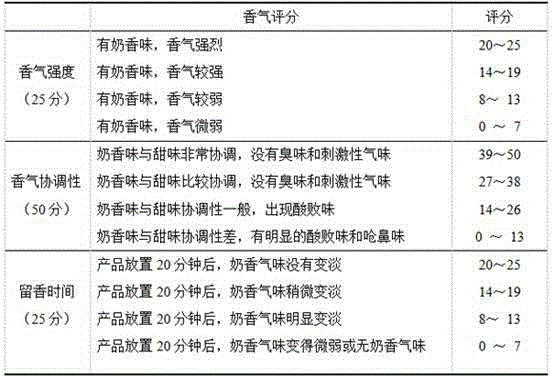

Image

Examples

Embodiment 1

[0033] 1) Weigh an appropriate amount of butter, add water and whey powder, wherein the amount of water added is 40% of the mass of butter, and the amount of whey powder added is 25% of the mass of butter, pre-sterilized at 75°C for 20 minutes, and cooled to room temperature;

[0034] 2) Add lipase and mix evenly, wherein the amount of enzyme added is 0.15% of the mass of butter, enzymolyze at 45°C for 5 hours, and inactivate the enzyme at 90°C for 10 minutes;

[0035] 3) Add protease and mix evenly, wherein the amount of enzyme added is 0.03% of the mass of butter, enzymatically hydrolyze at 45°C for 8 hours, and inactivate the enzyme at 90°C for 10min to obtain enzymatic hydrolyzate a;

[0036] 4) Add lactose and mix evenly. The amount of lactose added is 8% of the mass of the enzymatic solution a. After reacting at 90°C for 30 minutes, the natural milk flavor base is prepared.

[0037] Conclusion: The obtained milk-flavored base material is sweet and milk-flavored, with a s...

Embodiment 2

[0039] 1) Weigh an appropriate amount of butter, add water and whey powder, the amount of water added is 40-60% of the mass of butter, and the amount of whey powder added is 25% of the mass of butter, pre-sterilize at 70-80°C for 16-24min, and cool down to room temperature;

[0040] 2) Add lipase and mix evenly, wherein the amount of enzyme added is 0.15% of the mass of butter, enzymolyze at 45°C for 5 hours, and inactivate the enzyme at 90°C for 10 minutes;

[0041] 3) Add protease and mix evenly, wherein the amount of enzyme added is 0.03% of the mass of butter, enzymatically hydrolyze at 45°C for 8 hours, and inactivate the enzyme at 90°C for 10min to obtain enzymatic hydrolyzate a;

[0042] 4) Add lactose and mix evenly. The amount of lactose added is 8% of the mass of the enzymatic solution a. After reacting at 90°C for 30 minutes, the natural milk flavor base is prepared.

[0043] Conclusion: The obtained milk-flavored base material is sweet and milky-flavored, with a s...

Embodiment 3

[0045] 1) Weigh an appropriate amount of butter, add water and whey powder, wherein the amount of water added is 40% of the mass of butter, and the amount of whey powder added is 25% of the mass of butter, pre-sterilized at 75°C for 20 minutes, and cooled to room temperature;

[0046] 2) Add lipase and mix evenly, wherein the amount of enzyme added is 0.15% of the mass of butter, enzymolyze at 45°C for 5 hours, and inactivate the enzyme at 90°C for 10 minutes;

[0047] 3) Add protease and mix evenly, wherein the amount of enzyme added is 0.03% of the mass of butter, enzymatically hydrolyze at 45°C for 8 hours, and inactivate the enzyme at 90°C for 10min to obtain enzymatic hydrolyzate a;

[0048] 4) Add lactose and mix evenly. The amount of lactose added is 6-9% of the mass of the enzymatic solution a. After reacting at 90°C for 30 minutes, the natural milk flavor base is prepared.

[0049] Conclusion: The obtained milk-flavored base material is sweet and milky-flavored, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com