Swarm robot collaborative scheduling measurement and control method and system platform

A collaborative scheduling, group robot technology, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as low production efficiency, large floor space, and a single designated action of the robot, so as to improve production efficiency and save production. The effect of equipment investment and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

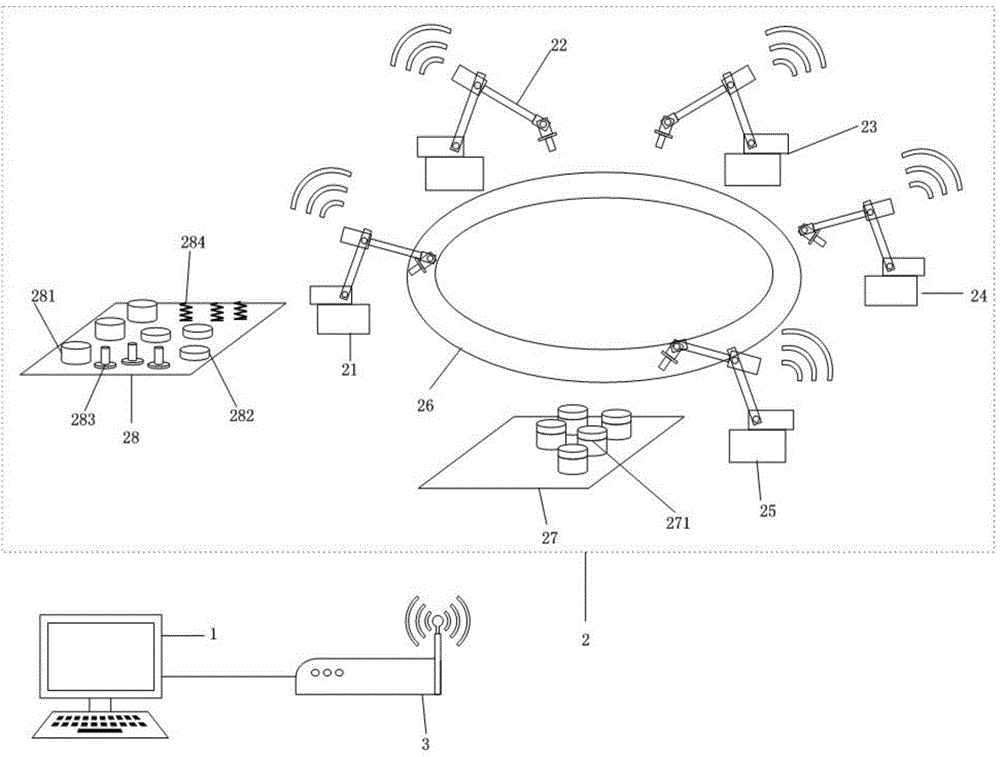

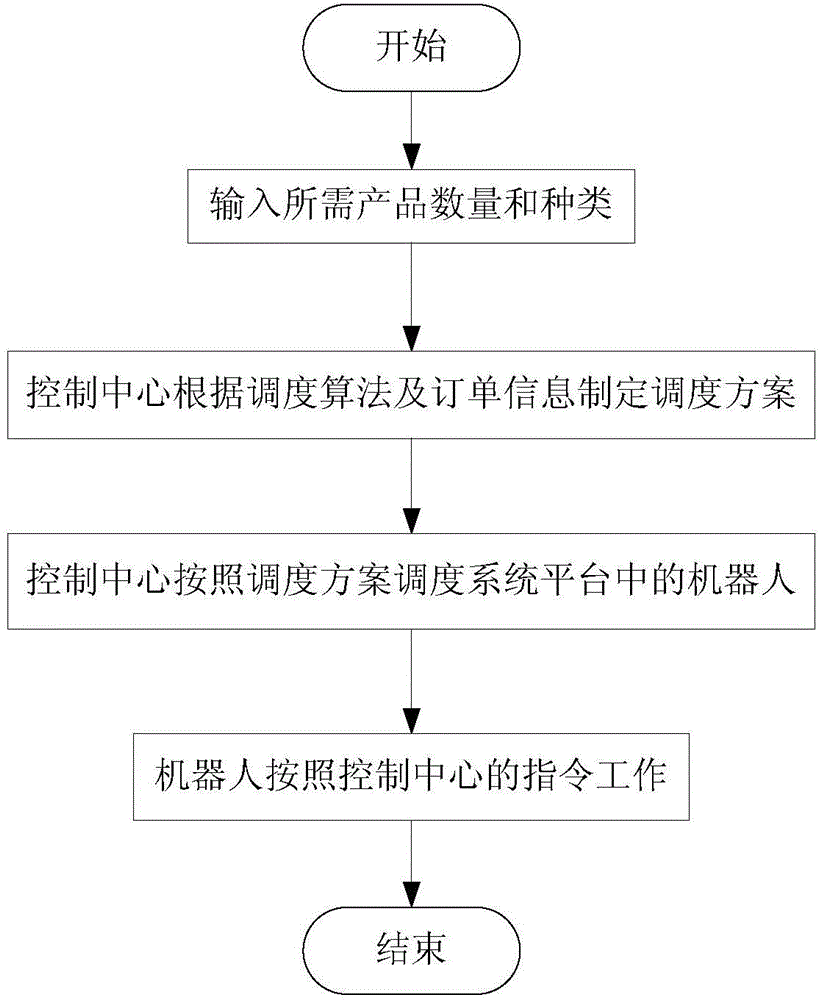

[0021] like figure 1 As shown, the group robot cooperative scheduling measurement and control system platform of the present invention includes a control center 1, a robot workstation 2, and a wireless module 3 for realizing platform wireless communication. The control center 1 and the robot workstation 2 form an interconnected network with the control center 1 as the center. Use Wifi wireless network communication technology for communication.

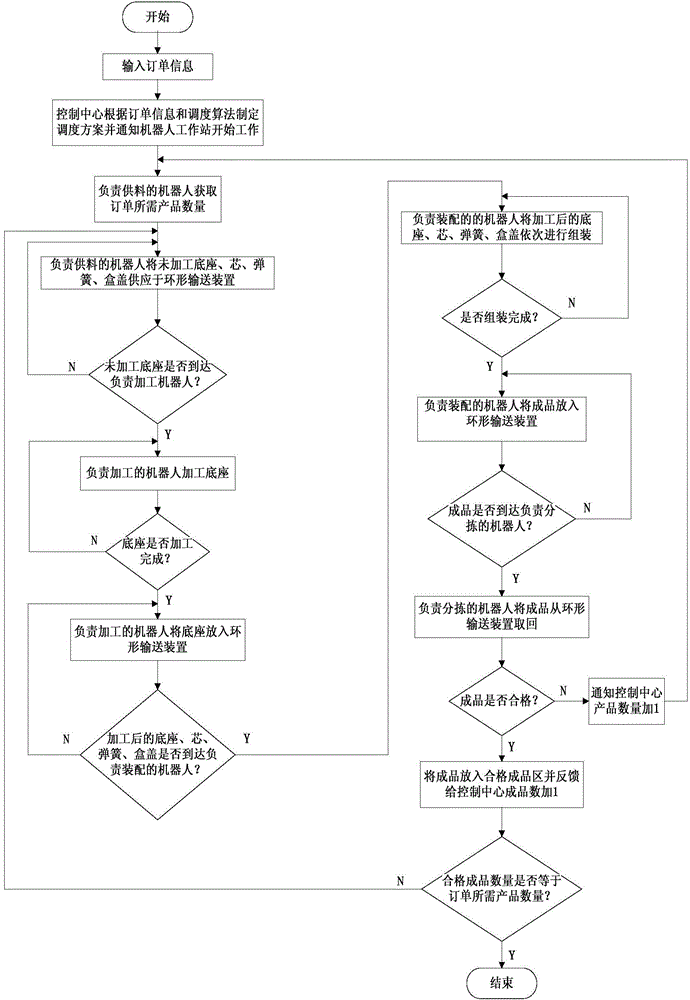

[0022] The robot workstation 2 includes a circular conveying device 26, and several intelligent robots are arranged around the circular conveying device 26. Each intelligent robot has a feeding module, a processing module, an assembly module, a sorting module and a communication module that can communicate with the wireless module 3. The module has the functions of feeding, processing, assembling and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com