Method for realizing coaxiality of inner and outer cone mirrors for producing hollow beams

A technology of hollow beams and conical mirrors, which is applied in the field of optics, can solve problems such as the lack of installation and adjustment technology of the inner and outer conical mirror optical systems, and achieve the effect of effective and fast installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

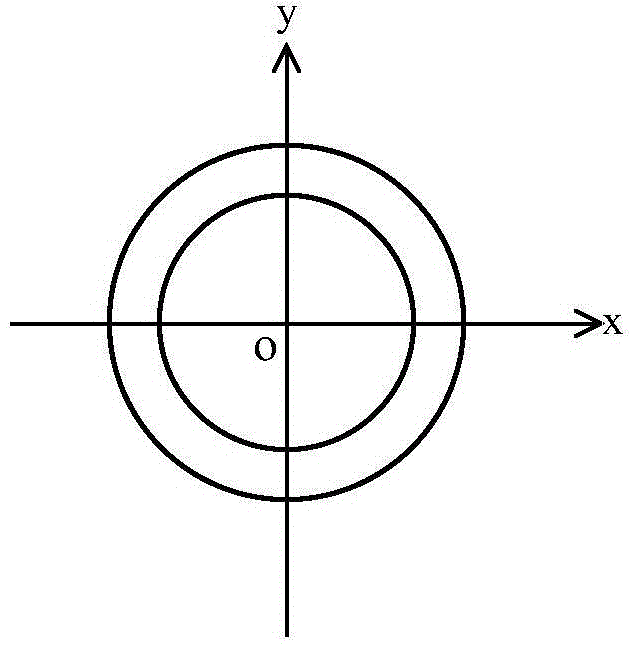

[0009] The implementation of the present invention is used to produce the coaxial method of the inner and outer conical mirrors of the hollow light beam. The specific embodiment is as follows, as Figure 5 shown. At first, on the display 1, display the standard bull's-eye of assembly: the display device 1 is preset as the display device of the CCD image sensor 3 by the character superposition module program; the character superposition module 2 is connected between the CCD image sensor 3 and the display 1, by The program of the character overlay module designates the center of the pixel array of the CCD image sensor 3 as the center of the optical image, and displays it on the display 1 as the bull's-eye of the adjustment reference. Secondly, establish a reference light path: the light path given by the laser 4 is collimated by the telescopic system 5 and then divided into two beams whose optical paths are perpendicular to each other by the half-mirror 6. The light path is He-N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com