Three-dimensional imaging method of wood internal defects based on top-k inverse distance weighting

An inverse distance weighting, wood interior technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of low implementation efficiency, high cost, difficult to implement, etc., to achieve high imaging accuracy, simple technology, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

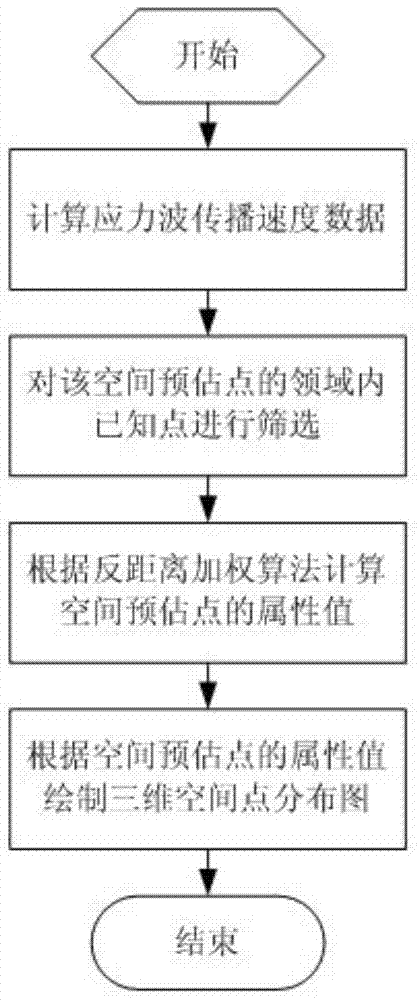

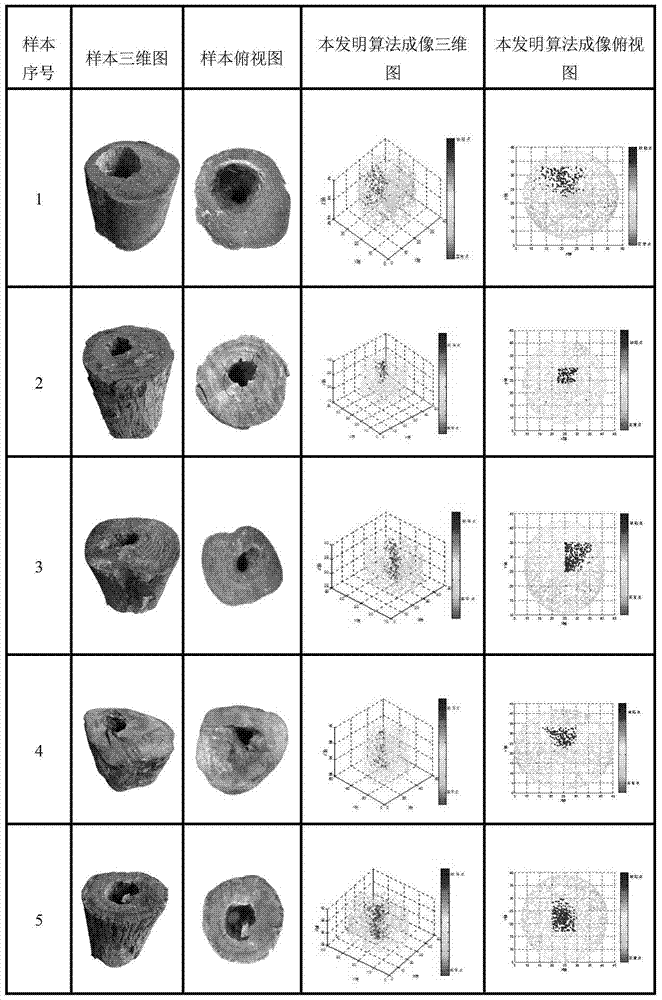

[0036] The three-dimensional imaging method of wood internal defects based on Top-k inverse distance weighting proposed by the present invention, refer to figure 1 , including the following steps:

[0037] Fix the sensors around the wood to be tested so that the sensors are evenly distributed around the wood to be tested and the sensors are fixed at different heights around the wood to be tested, wherein the maximum height difference between the sensors fixed on the wood to be tested ranges from 15cm to 30cm, tap the sensors one by one to make the stress wave propagate inside the material to be tested, record the propagation time of the stress wave inside the wood, and calculate the propagation speed of the stress wave between any two sensors;

[0038] According to the stress wave propagation velocity data, the known point velocity data set in the neighborhood of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com