Online visual inspection device and method for surface dirt of group origin eggs

A visual inspection device and technology for poultry eggs, which are applied in the direction of optical testing for flaws/defects, etc., can solve the problems of difficulty in batch inspection, large influence of egg shell color, lower detection accuracy, etc., and achieve the effect of good application and promotion prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

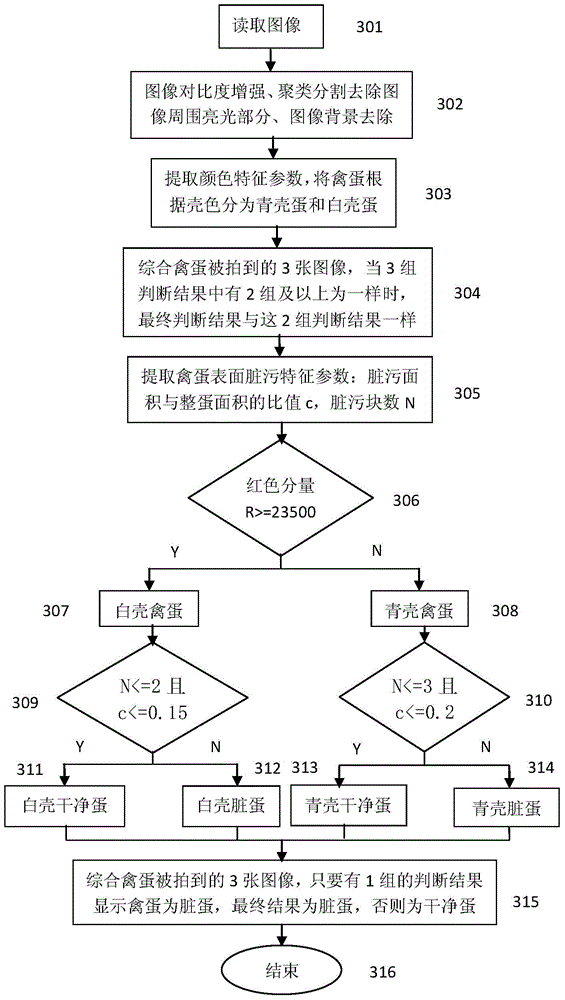

[0070] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0071] 1. Device

[0072] 1. Overall

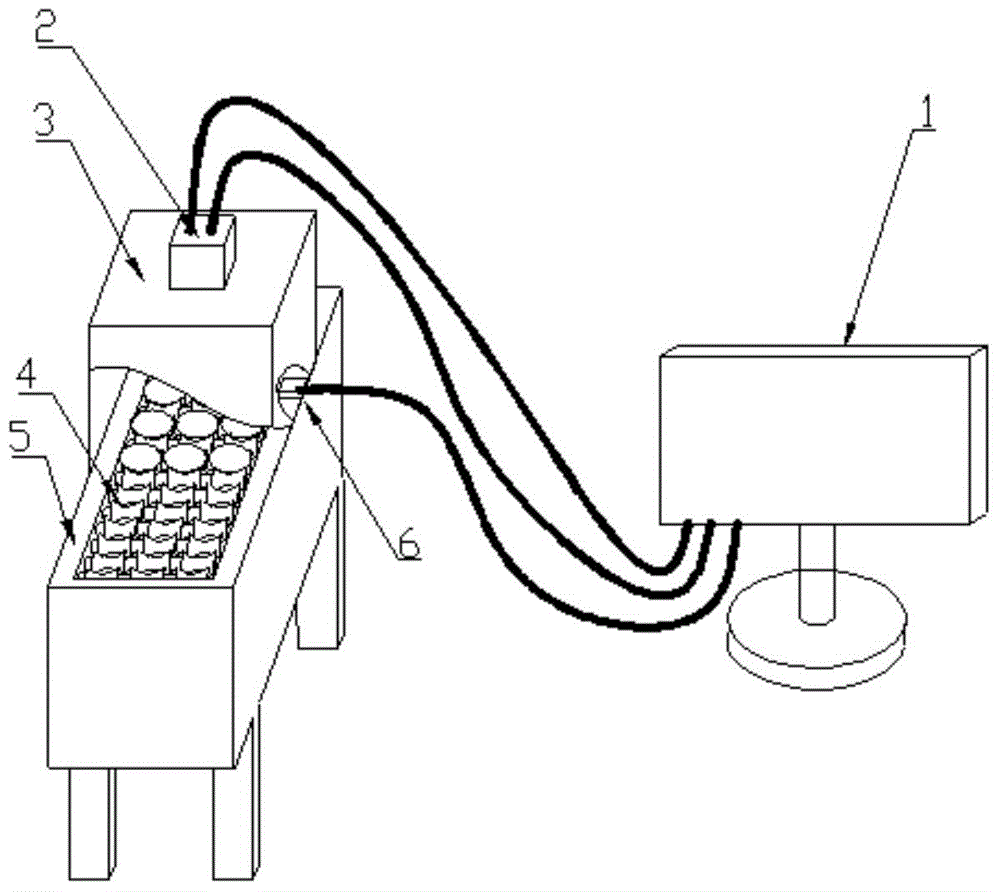

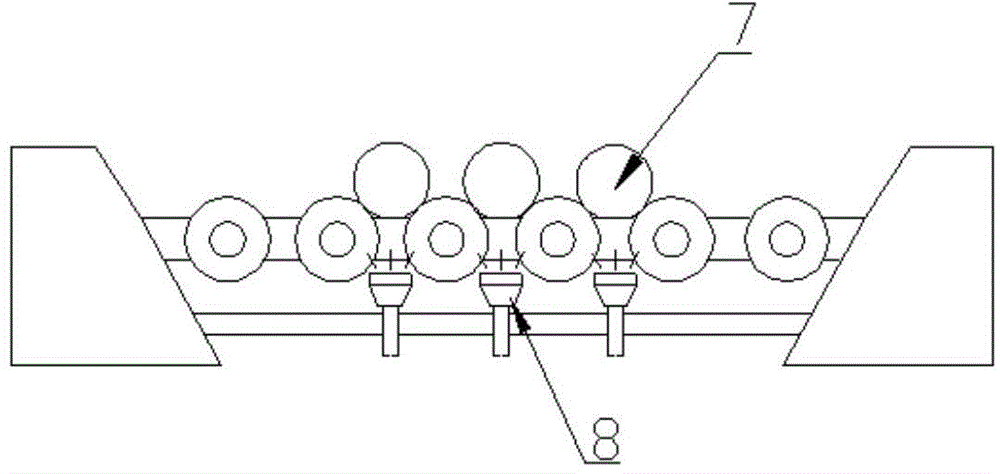

[0073] like figure 1 , figure 2 , the device is composed of a computer 1, an industrial camera 2, a camera obscura 3, a conveyor belt 4, a device table 5, a photoelectric sensor 6, poultry eggs 7 and a light source 8;

[0074] Its location and connection relationship are:

[0075] A conveyor belt 4 is installed on the device table 5, a dark box 3 is arranged above the conveyor belt 4, and an industrial camera 2 is arranged in the middle of the top of the dark box 3; The poultry egg 7 placed on the conveyor belt is transmitted through the gap; a photoelectric sensor 6 is arranged under the side of the dark box 3, and when the poultry egg 7 runs to the same level as the photoelectric sensor 6, the photoelectric sensor 6 is triggered; the industrial camera 2 communicates with the computer through a data line 1 connected.

[0076] 2. Functional c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com