First-order buoyancy principle based magnetic liquid damping shock absorber with magnetic shielding covers

A technology of magnetic liquid and magnetic isolation cover, which is applied in the direction of shock absorber, magnetic spring, spring/shock absorber, etc., can solve the problems of difficult flow of magnetic liquid, fragile permanent magnet, and can not be applied, so as to reduce leakage Magnetic phenomenon, avoid flow difficulties, enhance the effect of frequency difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described with accompanying drawing as specific embodiment:

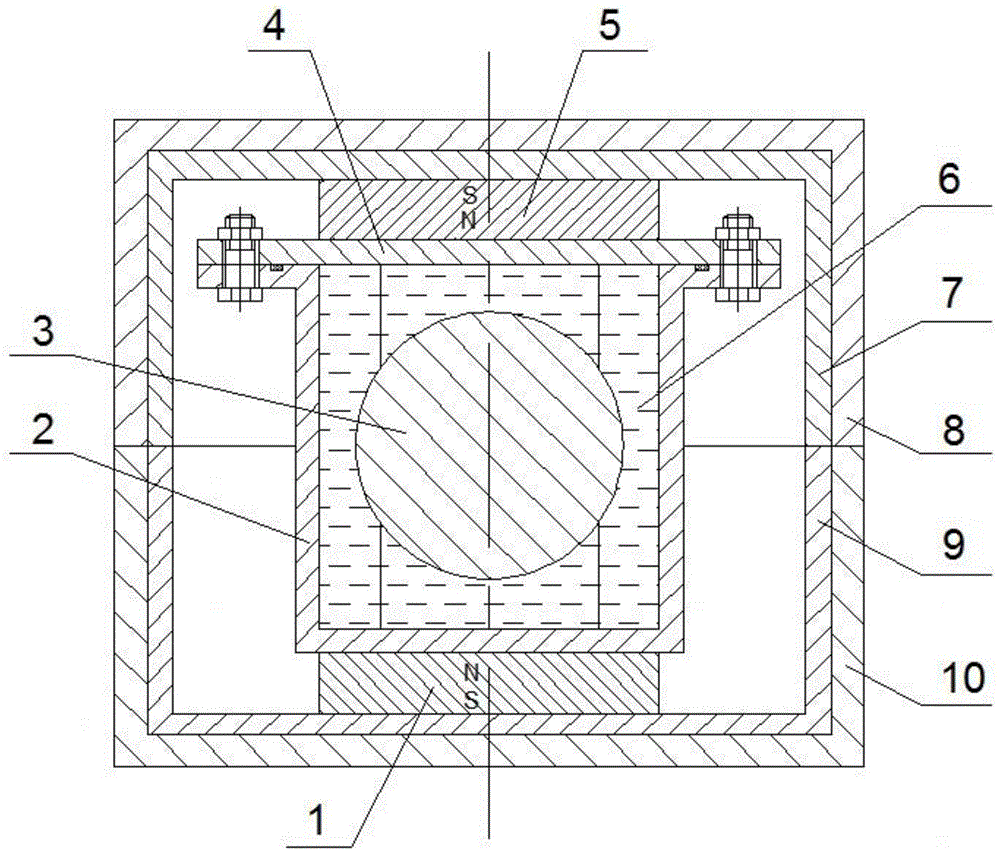

[0026] A first-order buoyancy principle magnetic liquid damping shock absorber with a magnetic isolation cover, such as figure 1 , the vibration damping device includes: a first permanent magnet 1, a housing 2, a mass block 3, an end cover 4, a second permanent magnet 5, a magnetic liquid 6, an upper magnetically conductive inner sleeve 7, an upper magnetically isolated outer sleeve 8, a lower guide Magnetic inner sleeve 9, the lower magnetic insulation overcoat 10.

[0027] Connections between the parts making up the device:

[0028] First inject the magnetic liquid 6 into the shell 2, and stop injecting the magnetic liquid when the height of the magnetic liquid 6 is half of the height of the shell 2. Then put the mass block 3 into the housing 2, and after the mass block 3 completely sinks into the bottom of the housing 2, continue to inject the magnetic liquid 6 into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com