Efficient pressure buildup device for die casting machine

A die-casting machine, high-efficiency technology, used in fluid pressure actuation devices, mechanical equipment, fluid pressure converters, etc., which can solve problems such as long time and influence on pressure build-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

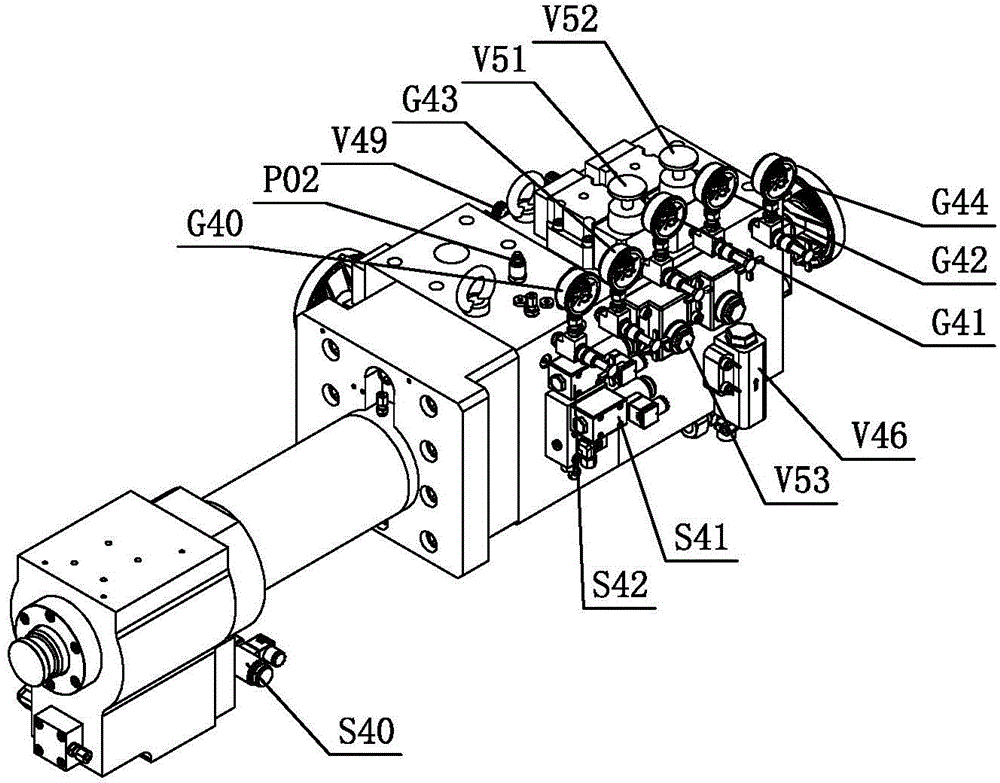

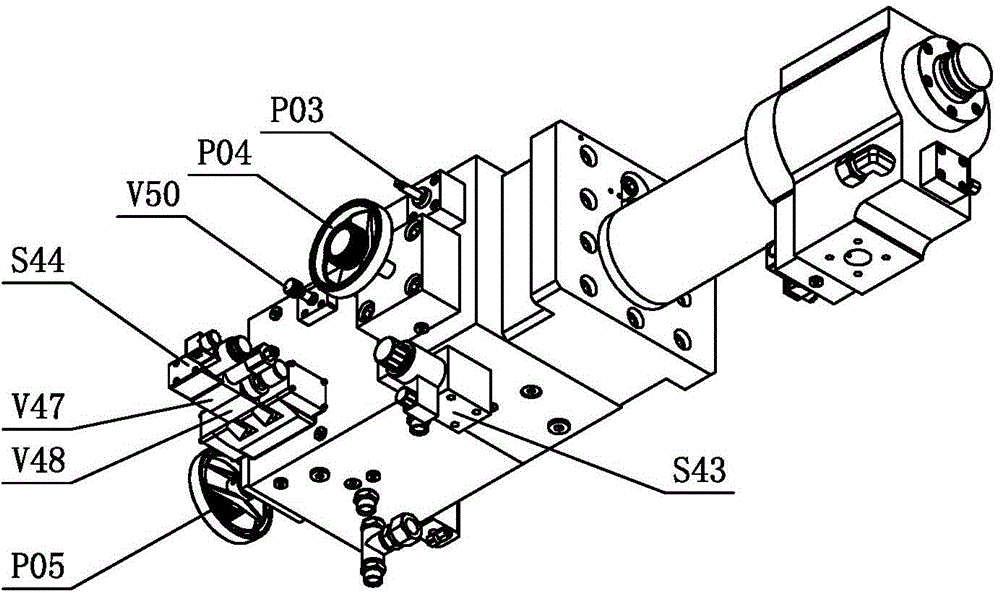

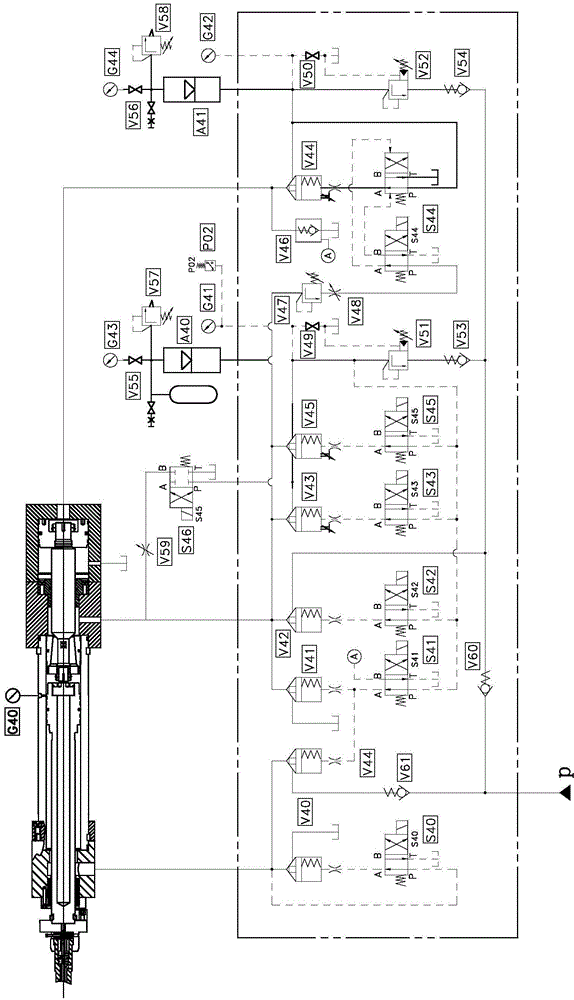

[0016] see Figure 1-Figure 3 , the high-efficiency pressure building device for die-casting machines includes a pressurized oil cylinder and an injection oil cylinder, and also includes a fourth cartridge valve V43 and a fourth electromagnetic reversing valve S43 connected in series on the oil circuit, and a first cartridge connected in series The valve V40 and the first electromagnetic reversing valve S40, the third cartridge valve V42 and the third electromagnetic reversing valve S42 connected in series, the sixth cartridge valve V45 and the sixth electromagnetic reversing valve S45 connected in series, and the interconnected The fifth cartridge valve V44 and the throttling screw V61, the first accumulator A40 connected in series, the first pressure reducing valve V51 and the first one-way valve V53, the overflow valve V47 connected to each other and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com