Hole collapse preventive trenching construction method of underground diaphragm wall

An underground continuous wall and grooved construction technology, which is applied in excavation, infrastructure engineering, construction, etc., can solve problems such as ground subsidence, increase in concrete volume, affecting the normal use of surrounding buildings and municipal facilities, and reduce engineering accidents. , Improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

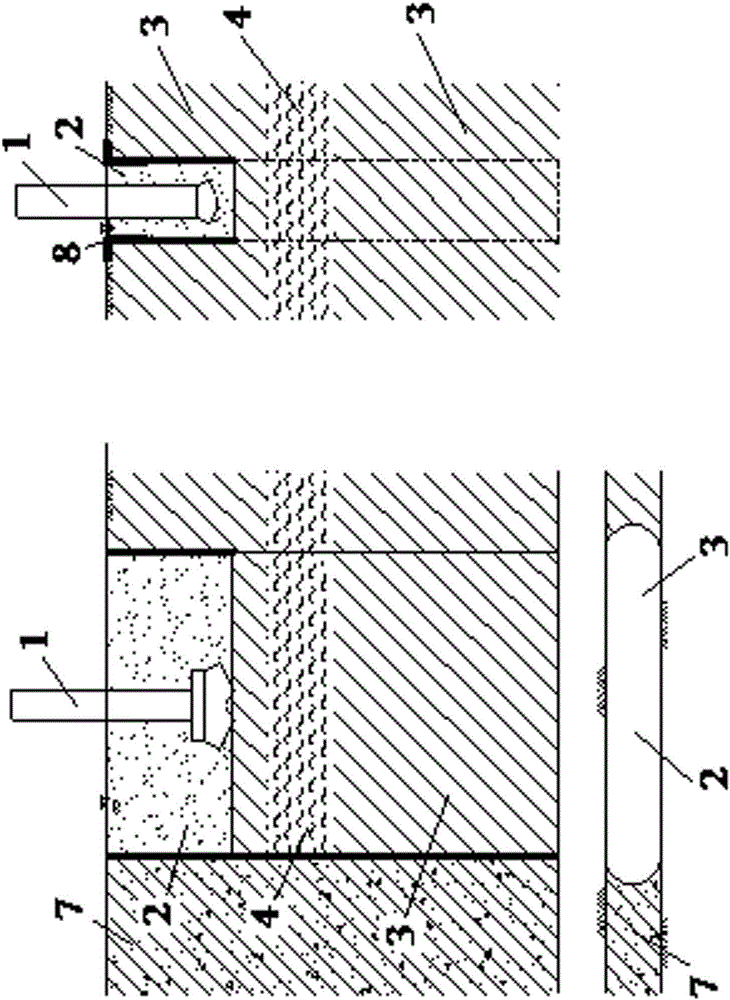

[0022] Example 1 : The first step: such as figure 1 As shown, measure the positioning, determine the excavation position of the guide wall 8, make the guide wall 8, prepare the mud 2, and prepare the mud circulation system, the trough forming machine is in place, the set deviation requirements are reviewed, and the trough forming machine is started. Troughing machine grab 1 starts to take soil to form a trough;

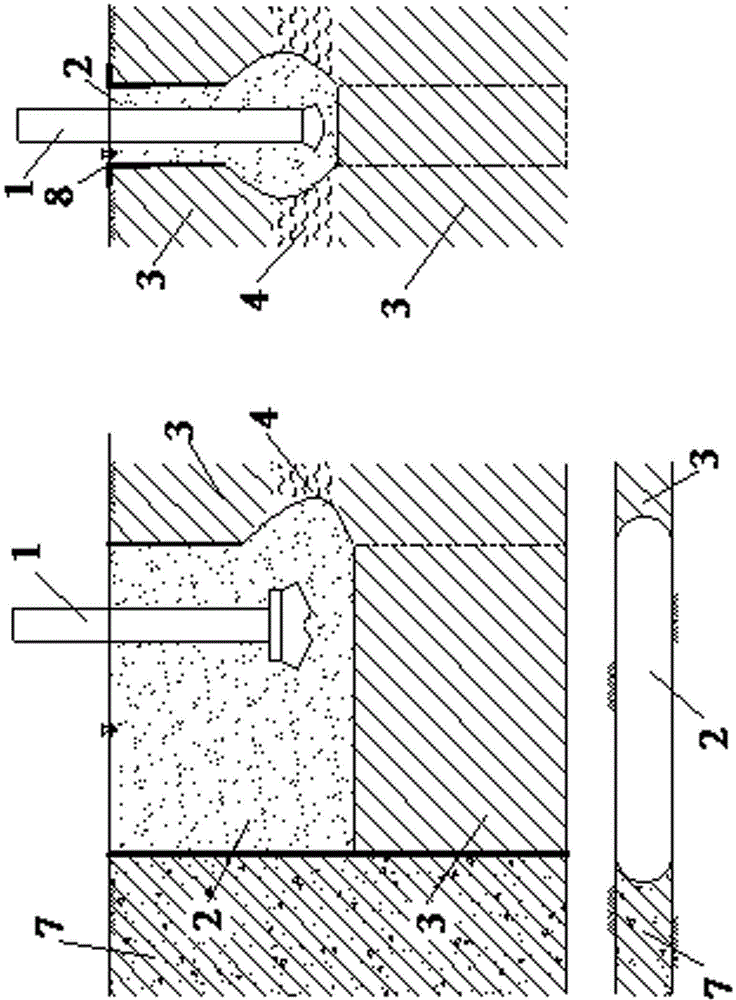

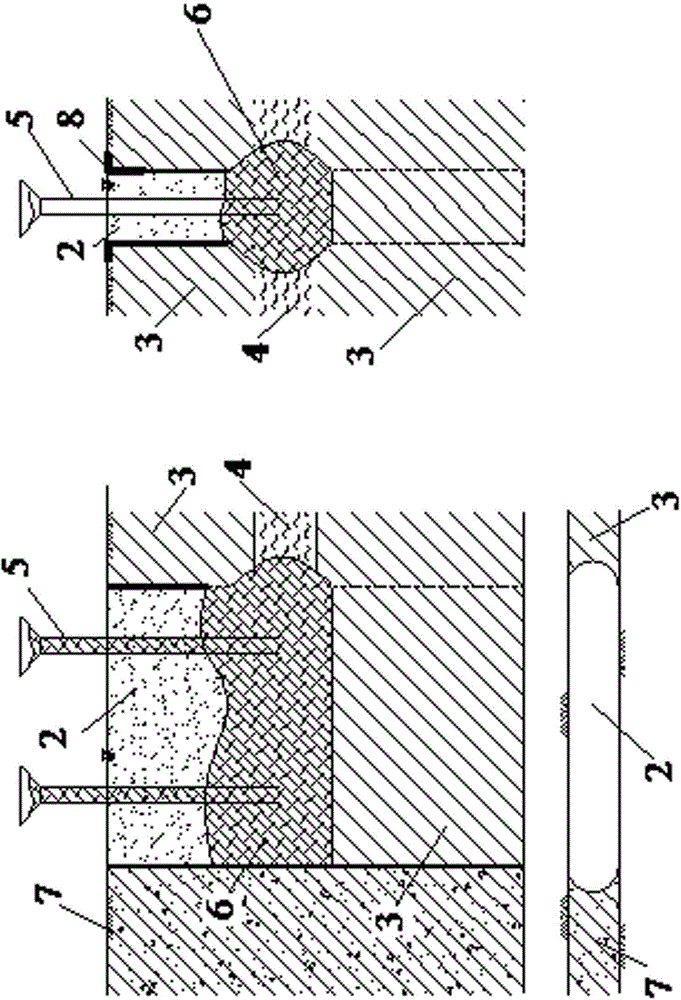

[0023] The second step: such as figure 2 As shown, the trough forming machine excavates soil in the soil layer 3 to form a trough, and maintains the mud water level in the trough section during trough formation to ensure that the hydrostatic pressure generated by the mud meets the design requirements. When the trough reaches the weak soil layer 4, if the trough wall collapses, such as a large amount of mud leakage in the trough, the mud level will drop significantly; a lot of foam or agitation appears in the mud 2; the amount of mud discharged is significantly larger th...

Embodiment 2

[0027] Example 2 : The first step: such as figure 1 As shown, measure the positioning, determine the excavation position of the guide wall 8, make the guide wall 8, prepare the mud 2, and prepare the mud circulation system, the trough forming machine is in place, the set deviation requirements are reviewed, and the trough forming machine is started. Troughing machine grab 1 starts to take soil to form a trough;

[0028] The second part: such as figure 2 As shown, the trough forming machine excavates soil in the soil layer 3 to form a trough, and maintains the mud water level in the trough section during trough formation to ensure that the hydrostatic pressure generated by the mud meets the design requirements. When the trough reaches the weak soil layer 4, if the trough wall collapses, such as a large amount of mud leakage in the trough, the mud level will drop significantly; a lot of foam or agitation appears in the mud 2; the amount of mud discharged is significantly larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com