Preparation method of intelligent surface mosquito-repellent polyester fiber for mosquito net

A polyester fiber and mosquito repellent technology, applied in the field of new functional smart fibers, can solve the problems of easy volatilization or decomposition of mosquito repellent, unsatisfactory mosquito repellent effect, and poor persistence of mosquito repellent effect, so as to prolong the timeliness of mosquito repellent , suitable for long-term storage and use, long-term slow-release mosquito repellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

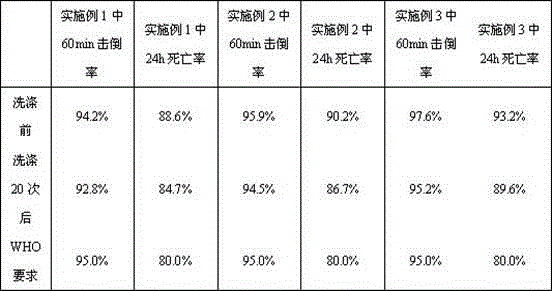

specific Embodiment 1

[0018] A preparation method of intelligent surface mosquito repellent polyester fiber for mosquito nets: comprising the following steps:

[0019] Step 1: Send the polyester fiber raw material into the YH400 type liquid flow automatic alkali weight reduction machine and use a weight reduction bath to carry out weight reduction treatment to obtain alkali-reduced polyester, wherein the weight reduction bath uses NaOH 5g / L and YF-002 refining agent 2g / L, and control the temperature at 90°C, and reduce the amount of time for 40min, then dry the alkali-reduced polyester at 80°C for 30min and then perform oxygen plasma treatment, in which the oxygen flow rate is 30cm 3 / min, radio frequency power 80W, treatment time 3min, obtain the polyester fabric that has introduced —COOH reactive group through the surface of etching, reduction treatment;

[0020] Step 2: Add 1g of mosquito repellent to 20ml of polyurethane adhesive resin, stir at 25°C for 20min, and add the silane coupling agent...

specific Embodiment 2

[0025] A preparation method of intelligent surface mosquito repellent polyester fiber for mosquito nets: comprising the following steps:

[0026] Step 1: Put the polyester fiber raw material into the YH400 liquid-flow automatic alkali weight reduction machine and use a weight reduction bath to carry out weight reduction treatment to obtain alkali-reduced polyester, wherein the weight reduction bath uses NaOH 10g / L and YF-002 refining agent 5g / L, and control the temperature at 90°C, and reduce the amount of time for 50min, then dry the alkali-reduced polyester at 85°C for 30min and then perform oxygen plasma treatment, in which the oxygen flow rate is 35cm 3 / min, radio frequency power 100W, treatment time 6min, obtain the polyester fabric that introduced —COOH reactive group through the surface of etching, decrement treatment;

[0027] Step 2: Add 2g of mosquito repellent to 25ml of polyurethane adhesive resin, stir at 25°C for 25min, and add silane coupling agent drop by dro...

specific Embodiment 3

[0032] A preparation method of intelligent surface mosquito repellent polyester fiber for mosquito nets: comprising the following steps:

[0033] Step 1: Put the polyester fiber raw material into the YH400 liquid flow automatic alkali weight reduction machine and use a weight reduction bath to carry out weight reduction treatment to obtain alkali-reduced polyester, wherein the weight reduction bath uses NaOH 15g / L and YF-002 refining agent 7g / L, and controlled temperature 90 ℃, weight reduction time 60min, then dry the alkali-reduced polyester at 90 ℃ for 30min and then treat it with oxygen plasma, in which the oxygen flow rate is 40cm 3 / min, radio frequency power 120W, processing time 10min, obtain the polyester fabric that has introduced —COOH reactive group through the surface of etching reduction treatment;

[0034] Step 2: Add 3g of mosquito repellent to 30ml polyurethane adhesive resin, stir at 25°C for 30min, and add silane coupling agent drop by drop, and the weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com