Papermaking sewage flocculant and preparation method thereof

A papermaking sewage and flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, processing wastewater treatment, etc., can solve the problems of high cost, secondary pollution, poor flocculation effect, etc., and achieve fast settlement speed and high improvement. The effect of excellent rate and coagulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

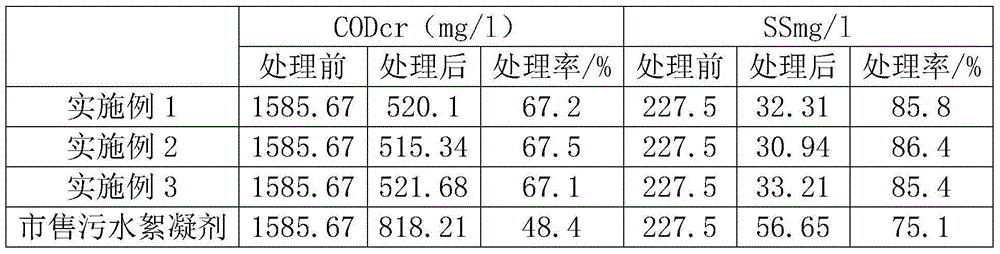

Examples

Embodiment 1

[0021] A kind of flocculant for papermaking sewage, the composition of the mass parts of the flocculant is as follows: 10 parts of modified chitosan, 5 parts of polyferric magnesium silicate, 5 parts of sodium carboxymethyl cellulose, 1 part of ferrate, 2 parts of raw gypsum parts, 12 parts of zeolite, 12 parts of activated carbon, 100 parts of distilled water; the ferrate is sodium ferrate.

[0022] Preferably, the modified chitosan is prepared by the following method: chitosan and glacial acetic acid are mixed to form chitosan acetic acid solution, then mixed with water-soluble polymer additive PS, and stirred in a constant temperature water bath at 60°C for 2 hours Finally, the desired modified chitosan is obtained; the molecular weight of the chitosan is 220,000.

[0023] Preferably, the pH value of the chitosan acetic acid solution is 4.5.

[0024] Preferably, the sodium ferrate is prepared by the following method: sodium peroxide and ferrous sulfate hydrate are heated a...

Embodiment 2

[0026] A papermaking wastewater flocculant, the mass parts of the flocculant are composed as follows: 15 parts of modified chitosan, 10 parts of polyferric magnesium silicate, 7 parts of sodium carboxymethyl cellulose, 6 parts of ferrate, 5 parts of raw gypsum parts, 13 parts of zeolite, 16 parts of activated carbon, 120 parts of distilled water, and the ferrate is sodium ferrate.

[0027] Preferably, the modified chitosan is prepared by the following method: chitosan and glacial acetic acid are mixed to form chitosan acetic acid solution, then mixed with water-soluble polymer additive PS, and stirred in a constant temperature water bath at 75°C for 1.5 After h, the desired modified chitosan was obtained.

[0028] Preferably, the chitosan has a molecular weight of 280,000.

[0029] Preferably, the pH value of the chitosan acetic acid solution is 5.

[0030] Preferably, the sodium ferrate is prepared by the following method: sodium peroxide and ferrous sulfate hydrate are hea...

Embodiment 3

[0032] A paper-making wastewater flocculant, the mass parts of the flocculant are composed as follows: 20 parts of modified chitosan, 15 parts of polyferric magnesium silicate, 8 parts of sodium carboxymethyl cellulose, 10 parts of ferrate, 8 parts of raw gypsum parts, 15 parts of zeolite, 20 parts of activated carbon, and 150 parts of distilled water; the ferrate is sodium ferrate.

[0033] Preferably, the modified chitosan is prepared by the following method: chitosan and glacial acetic acid are mixed to form chitosan acetic acid solution, then mixed with water-soluble polymer additive PS, and stirred in a constant temperature water bath at 80°C for 1 hour Finally, the desired modified chitosan is obtained.

[0034] Preferably, the chitosan has a molecular weight of 300,000.

[0035] Preferably, the pH value of the chitosan acetic acid solution is 5.5.

[0036] Preferably, the sodium ferrate is prepared by the following method: sodium peroxide and ferrous sulfate hydrate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com