Preparation method of anhydrous neodymium chloride

A neodymium chloride and pure water technology, applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., can solve the problems of poor solubility, high content of oxychloride, and can not fully meet user requirements, etc. Impurities, the effect of improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

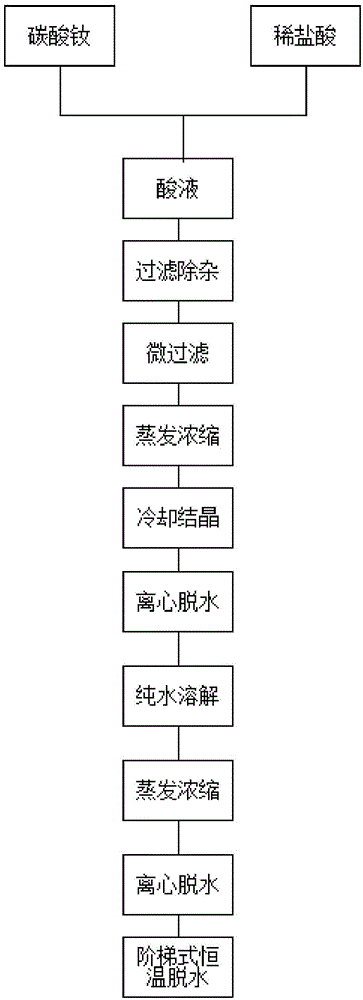

[0038] Such as figure 1 Shown, a kind of preparation method of anhydrous neodymium chloride comprises the following steps:

[0039] (1) 1 part of neodymium carbonate and 1.5 parts of dilute hydrochloric acid are added in the reactor to form a mixed solution;

[0040] (2) Acid

[0041] Adjusting the pH value of the mixed solution in step (1) to 1.5, stirring and reacting for 1 hour to obtain a mixed solution containing precipitate;

[0042] (3) Filtration and impurity removal

[0043] Obtain filtrate after the mixed solution that also has precipitation in step (2) is filtered through 1000 mesh sieves;

[0044] (4) microfiltration

[0045] The filtrate of step (3) is added into a microporous filter to obtain the filtrate after microfiltration;

[0046] (5) Evaporation and concentration

[0047] Heating the filtrate of step (4) to 150° C., and incubating for 5 hours to obtain a concentrated solution;

[0048] (6) cooling crystallization

[0049] Cool the concentrated solu...

specific Embodiment 2

[0066] A preparation method of anhydrous neodymium chloride, comprising the following steps:

[0067] (1) 1 part of neodymium carbonate and 2 parts of dilute hydrochloric acid are added in the reactor to form a mixed solution;

[0068] (2) Acid

[0069] Adjusting the pH value of the mixed solution in step (1) to 2, stirring and reacting for 1 hour to obtain a mixed solution containing precipitate;

[0070] (3) Filtration and impurity removal

[0071] Obtain filtrate after the mixed solution that also has precipitation in step (2) is filtered through 1000 mesh sieves;

[0072] (4) microfiltration

[0073] The filtrate of step (3) is added into a microporous filter to obtain the filtrate after microfiltration;

[0074] (5) Evaporation and concentration

[0075] Heating the filtrate of step (4) to 150° C., and incubating for 7 hours to obtain a concentrated solution;

[0076] (6) cooling crystallization

[0077] Cool the concentrated solution of step (5) to 20°C, crystalli...

specific Embodiment 3

[0094] A preparation method of anhydrous neodymium chloride, comprising the following steps:

[0095] (1) 1 part of neodymium carbonate and 1.8 parts of dilute hydrochloric acid are added in the reactor to form a mixed solution;

[0096] (2) Acid

[0097] Adjusting the pH value of the mixed solution in step (1) to 1.8, stirring and reacting for 1 hour to obtain a mixed solution containing precipitate;

[0098] (3) Filtration and impurity removal

[0099] Obtain filtrate after the mixed solution that also has precipitation in step (2) is filtered through 1000 mesh sieves;

[0100] (4) microfiltration

[0101] The filtrate of step (3) is added into a microporous filter to obtain the filtrate after microfiltration;

[0102] (5) Evaporation and concentration

[0103] Heating the filtrate of step (4) to 150° C. and insulated for 6 hours to obtain a concentrated solution;

[0104] (6) cooling crystallization

[0105] Cool the concentrated solution of step (5) to 20°C, crystal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com