Corrugated cardboard turning, stacking and unloading production line and its control method

A corrugated cardboard and production line technology, applied in the research field of corrugated cardboard blanking production line, can solve problems such as time-consuming, laborious, messy, and wear-and-tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

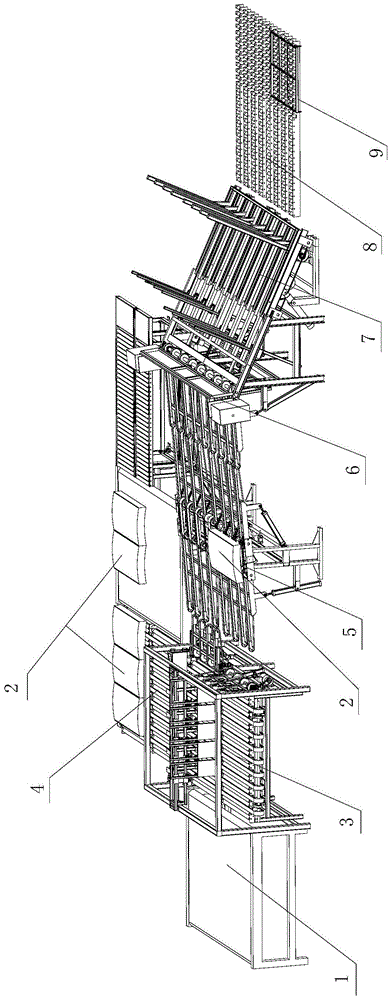

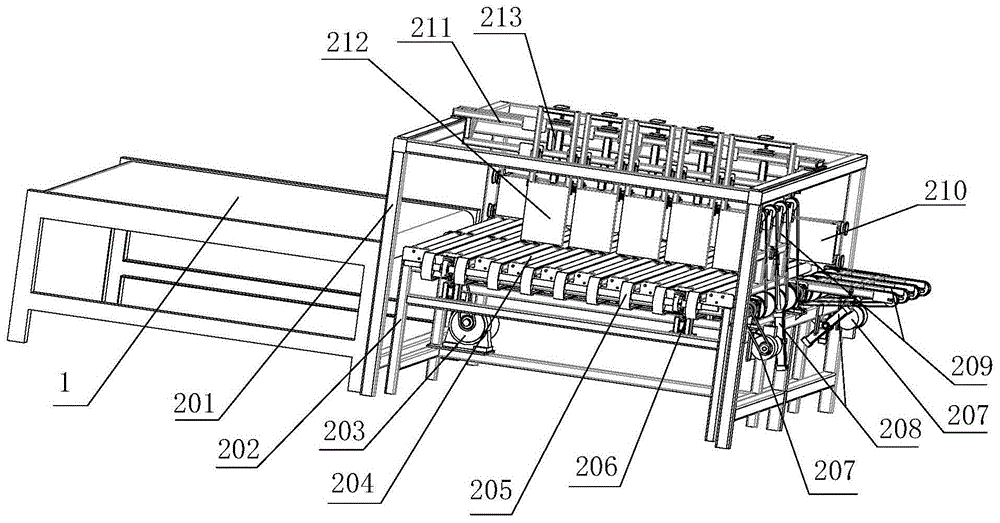

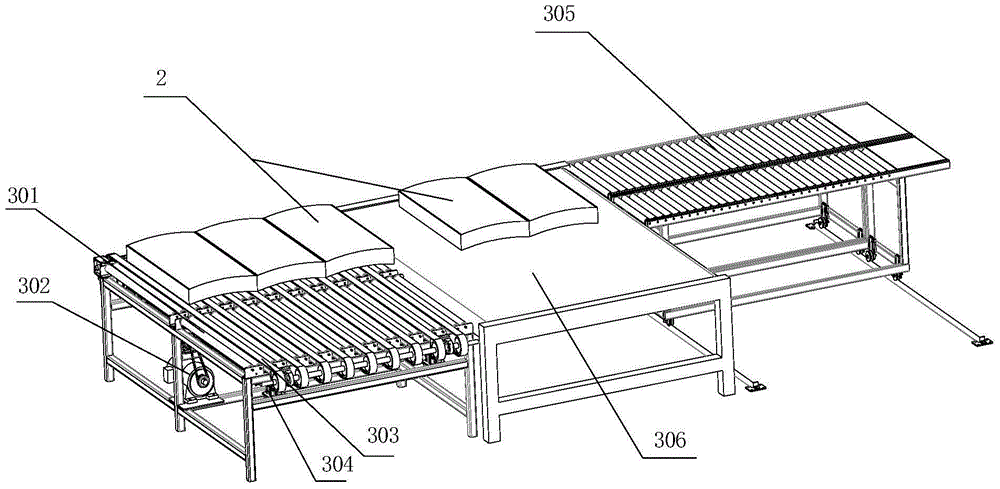

[0073] like figure 1 As shown, the corrugated cardboard turnover, stacking and unloading production line in this embodiment includes an automatic overturning and stacking line and a manual unloading backup device, wherein the automatic overturning and stacking line includes a paper separating and pushing device connected in sequence, a buckle type overturning device, Buffer moving device, stacking upright device, paper pile conveying device. The manual unloading standby device is arranged on the longitudinal side of the paper separating and pushing device. In practical application, it is also possible to only set the automatic turning and stacking line as the blanking production line. The reason why the manual blanking backup device is also provided in this embodiment is to prevent the automatic turning and stacking line from malfunctioning.

[0074] In this embodiment, the corrugated cardboards on the blanking production line are processed in groups, and each group is 4 in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com