Device for grinding ultrasonic wave guide probe

A technology of ultrasonic and sliding rails, which is used in material analysis, measuring devices, and grinding machines using sonic/ultrasonic/infrasonic waves. It can solve problems such as uneven force, scrapped probes, and irregular shapes to ensure accurate positioning and enhance stability. function, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is further described in conjunction with the following examples.

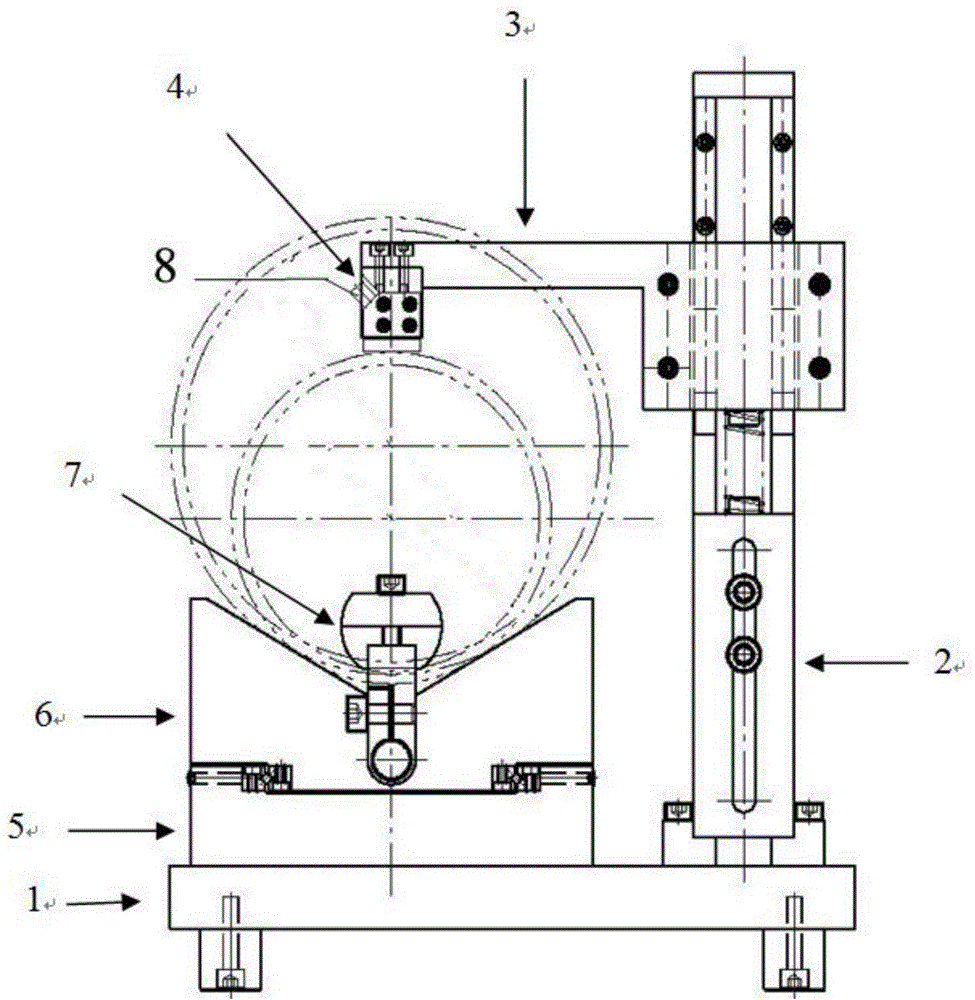

[0023] The embodiment of the present invention provides a device for grinding the ultrasonic guided wave probe, which is used for grinding the probe 8, such as figure 1 As shown, it includes a base 1, a column 2, a cantilever 3, a probe fixture 4, a slide rail base 5, a V-shaped sample tube fixing groove 6 and a sample tube fixing card 7.

[0024] The base 1 is located at the lower part of the device, and an adjustment member that can adjust the level of the base 1 is arranged below it, and the adjustment member is vertically arranged with the base 1 . The upright column 2 is arranged on one side above the base 1 , preferably, the upright column 2 is perpendicular to the base 1 , and the upright column 2 is fixedly connected to the base 1 through the bolt holes arranged above the base 1 . One end of the cantilever 3 is clamped on the column 1, and it can slide vertically up and dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com