Bending system and method with detection feedback function and phased bending function

A detection feedback, staged technology, applied in the field of sheet metal processing, can solve the problems of inability to adjust, excessive bending, safety hazards, etc., to achieve the effect of convenient height and angle, reduce the proportion of cracks, and prevent excessive bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be described below in conjunction with the drawings.

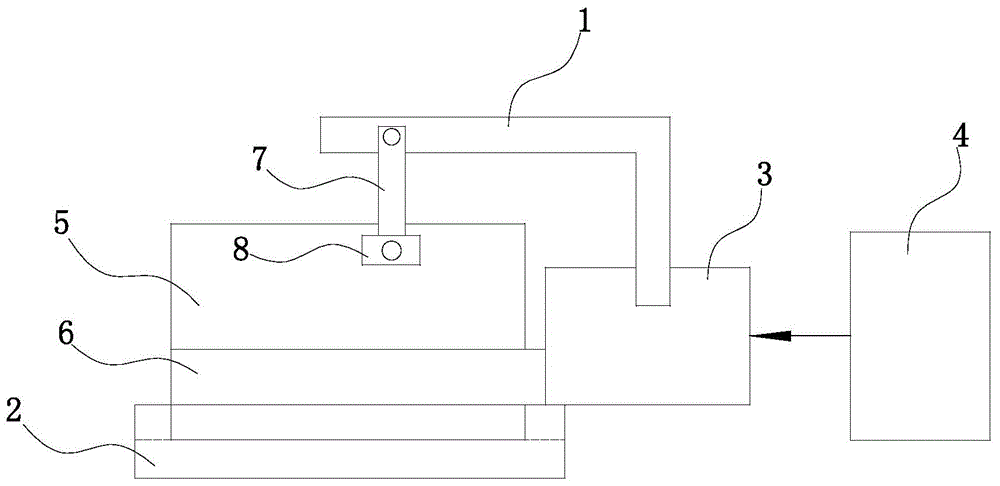

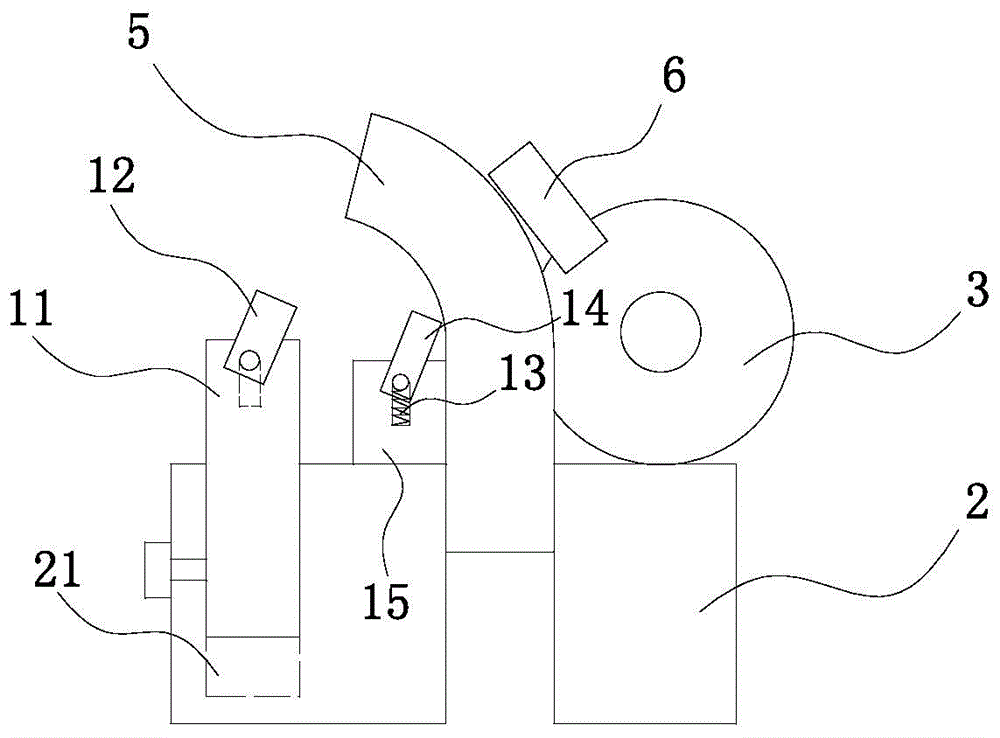

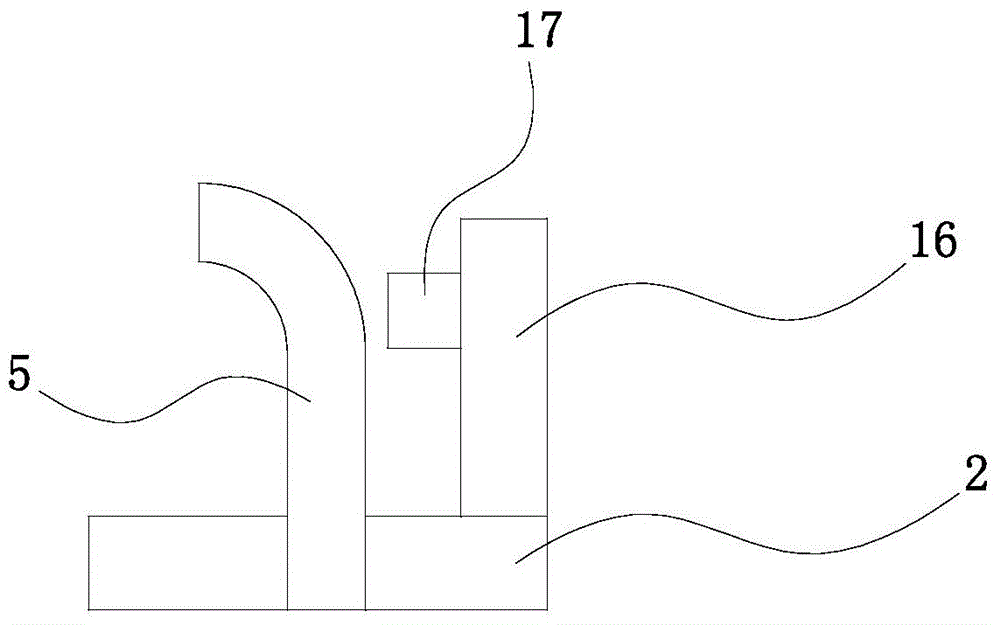

[0028] Such as Figure 1 to Figure 4 As shown, the bending processing system with detection feedback and stepwise bending of this embodiment includes a drive motor 3 installed on the frame 1, a clamping fixture 2 and a host 4 that controls the drive motor 3. A bending shaft 6 is installed on the motor shaft of the motor 3, and the workpiece 5 is installed on the clamping fixing seat 2;

[0029] It also includes a capacitance sensing thickness detector 8 installed on the frame 1 with the aid of a first bracket 7, a pressure sensor 14 and a proximity switch 12 installed on the clamping and fixing seat 2, a detection feedback device, and a controller 10 connected to the host 4, The pressure sensor 14 is installed in the installation groove of the stopper 15 by means of a spring 13, the stopper 15 is installed on the bending side of the workpiece 5, and the proximity sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com