Substrate tray and substrate processing apparatus including same

A substrate processing and substrate technology, applied in the field of substrate processing equipment, can solve problems such as process unevenness, substrate dislocation, and substrate pickup failure, and achieve the effects of increasing yield, preventing sinking, and preventing process defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

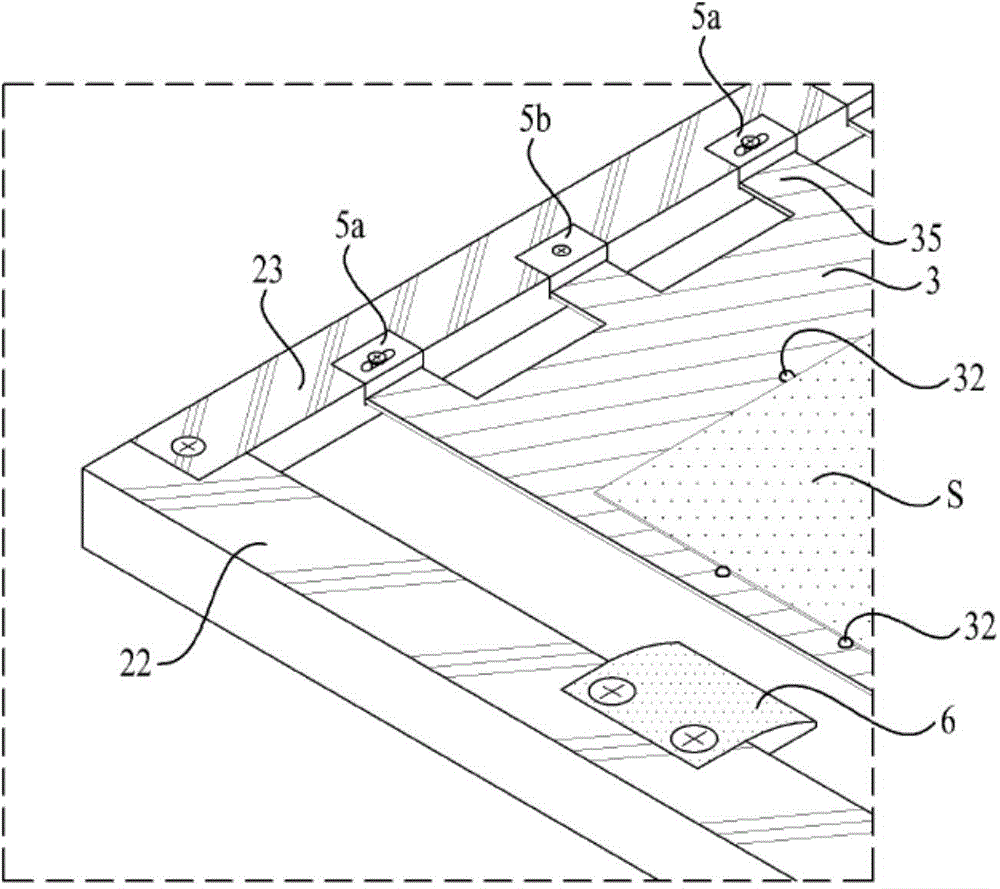

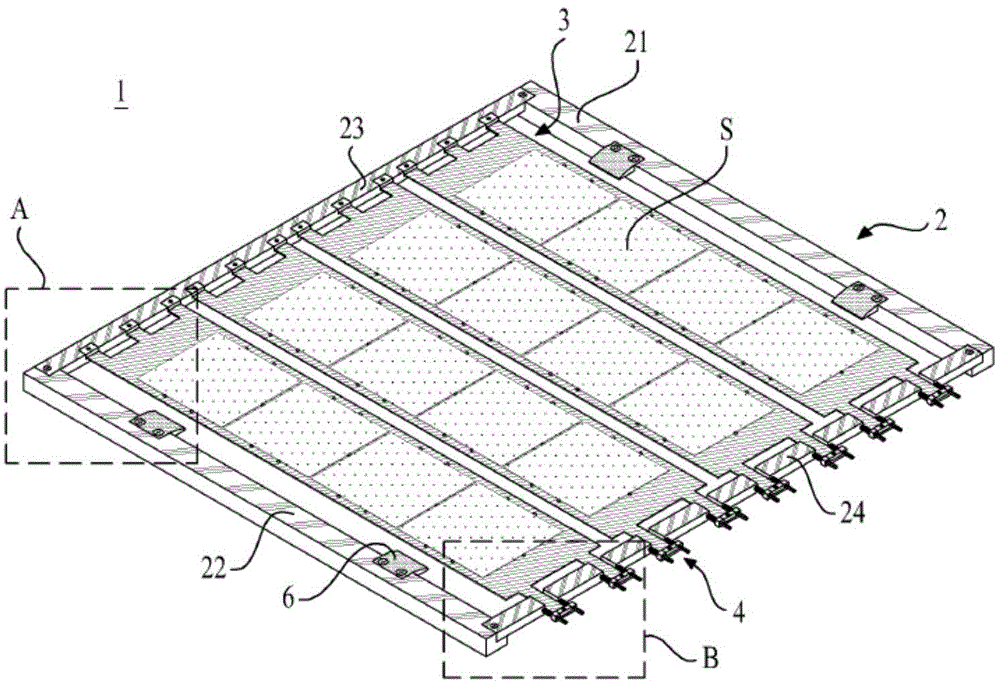

[0030] Description will be made in detail with reference to exemplary embodiments of the invention, which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers are used throughout the drawings to refer to the same or like parts.

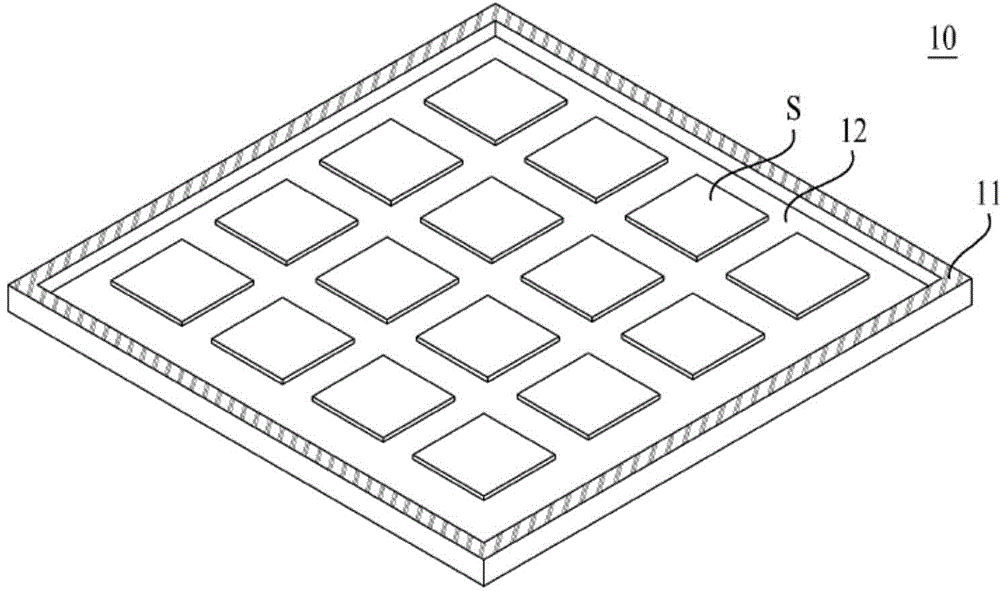

[0031] The substrate tray 1 according to the present invention functions to support a plurality of substrates (S) to be processed and load them into the substrate processing apparatus. Here, substrate processing, such as a deposition process, an etching process, a cleaning process, etc., may be performed on the substrate (S).

[0032] refer to figure 2 , the substrate tray 1 according to the present invention may include: a plurality of belts 3 for supporting a plurality of substrates (S) arranged in the first axis direction (X coordinate axis direction); A plurality of tapes 3 in the second axis direction (Y coordinate axis direction, perpendicular to the first axis direction) are combined. With respect to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com