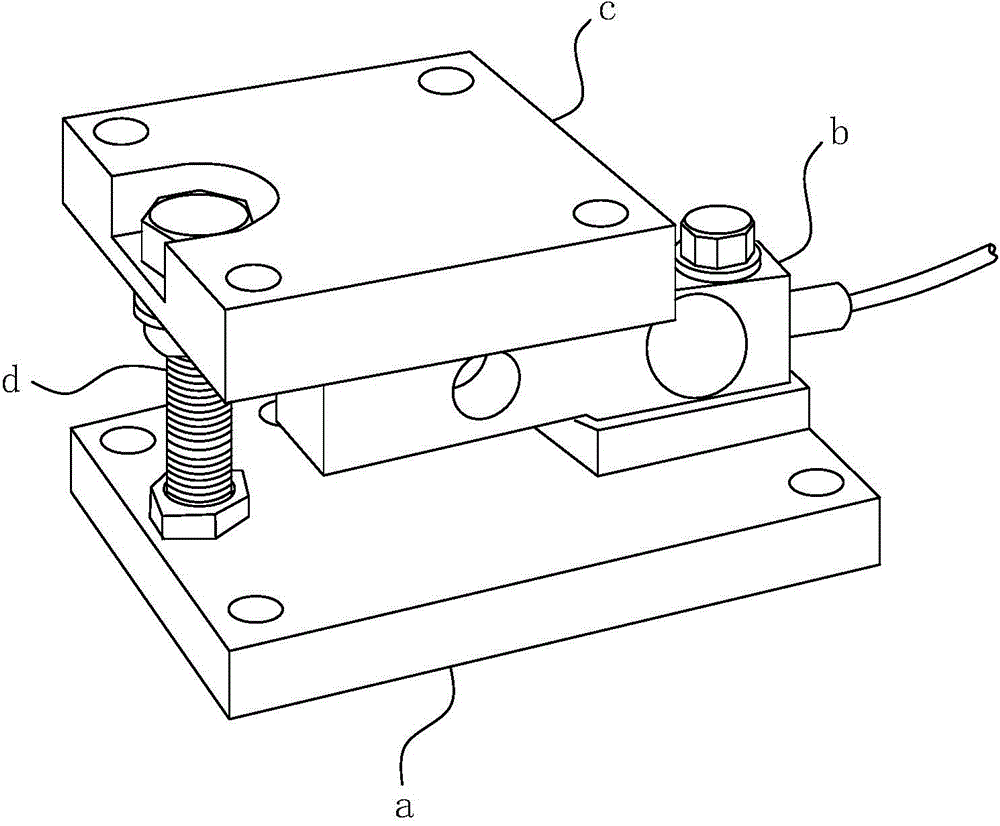

Sensor weighing module

A weighing module and sensor technology, which is applied in the field of weighing and packaging, can solve the problems of the sensor being suffocated, insensitive, and the weighing accuracy is enlarged, and achieves a system that is not easy to suffocate and lock up, the sensor is responsive, and the force sensitivity is guaranteed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

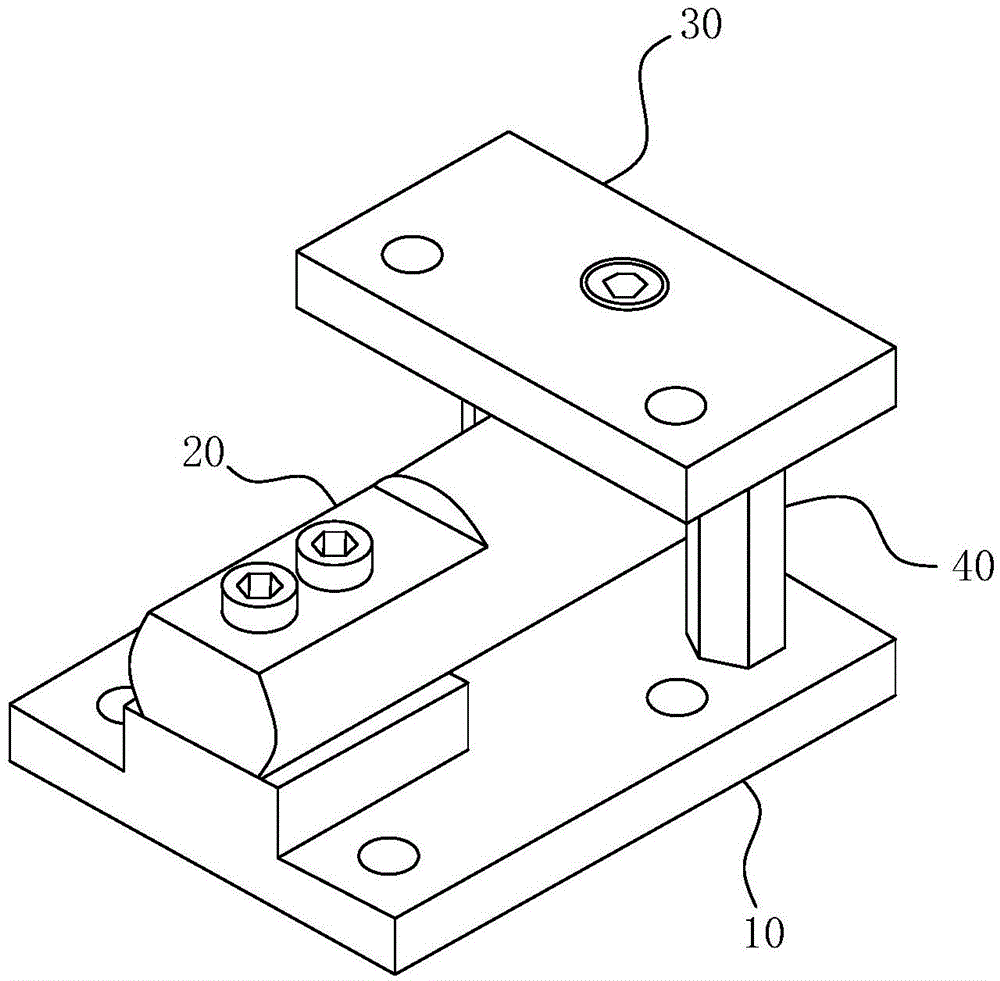

[0027] For ease of understanding, combined here Figure 2-5 The specific implementation structure and work flow of the present invention are further described as follows:

[0028] The actual structure of the present invention is as Figure 2-5As shown, it includes a base 10 as a bottom installation base, and a horizontal cantilever beam sensor 20 is arranged on the base 10. In actual selection, such as a Toledo load cell can be selected. The cantilever end of the beam sensor 20 is provided with a load-bearing plate 30 and the bolts are fixedly fitted between them. In terms of anti-overturning treatment, the load-bearing plate 30 is in the shape of a rectangular plate, and the center of gravity of the middle section forms the above-mentioned bolt connection point, and its two ends are respectively fixed by 10 bolts at the base and extend vertically upwards. The strut 40 performs balanced support at both ends. More specifically, a hemispherical spherical groove 41 is recessed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com