High-resolution dense fiber grating laying method

A fiber grating and high-resolution technology, which is applied in the direction of transmitting sensing components with optical devices, can solve the problem that a single optical fiber cannot provide sufficient spatial resolution, and achieve the effect of convenient material collection and improved spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The method for laying out high-resolution dense fiber gratings of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

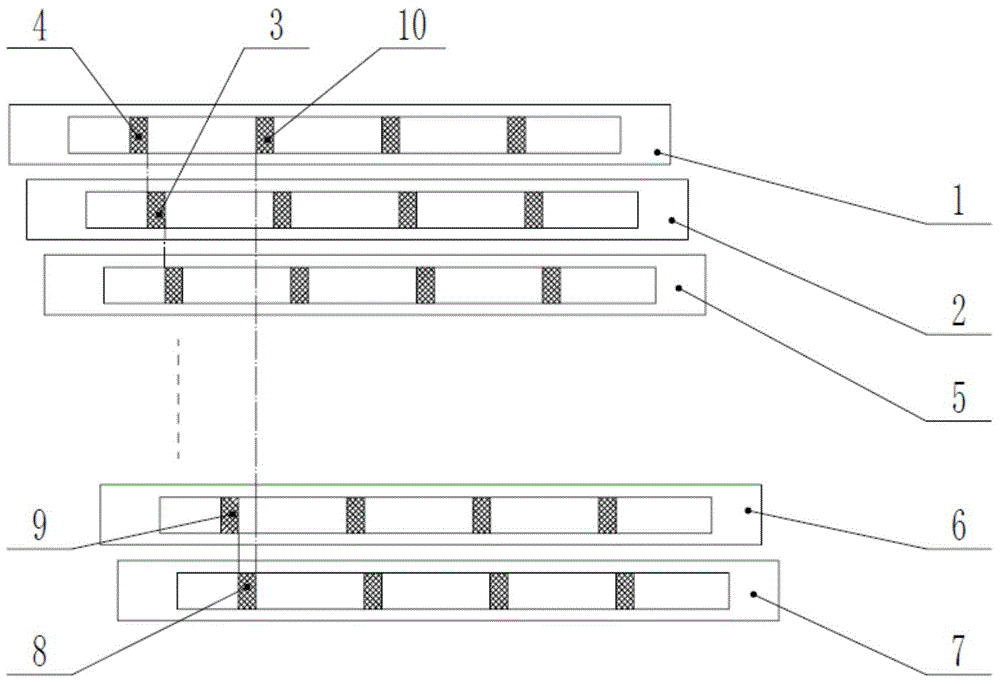

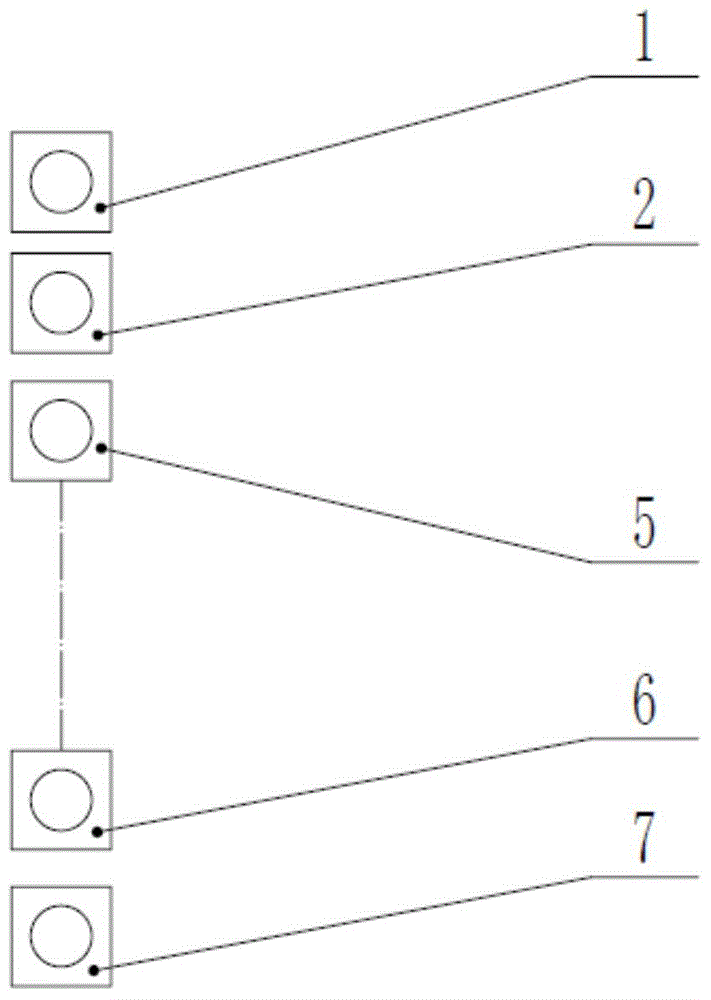

[0022] Such as figure 1 As shown, in this specific embodiment, the surface of the object to be tested is a plane where the fiber grating is to be bonded. In order to ensure that it can be decrypted and bonded with the plane, as figure 2 As shown, in this specific embodiment, the shape of the end face of each fiber Bragg grating is quadrangular. In other words, in this specific embodiment, the fiber Bragg grating is packaged in a square shape.

[0023] In this specific embodiment, the specific steps of the high-resolution dense fiber grating laying method of the present invention are as follows:

[0024] a. First, use absorbent cotton dipped in an appropriate amount of analytical pure alcohol to scrub the n optical fiber gratings to be bonded, and then put them in a drying oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com