Marine natural gas liquefaction and NGL recycling system and application

A recovery system and natural gas technology, applied in liquefaction, refrigeration and liquefaction, solidification, etc., can solve the problems of long construction period, flare ignition, high risk, etc., and achieve convenient start-up, shutdown and maintenance, compact equipment layout, and simplified equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

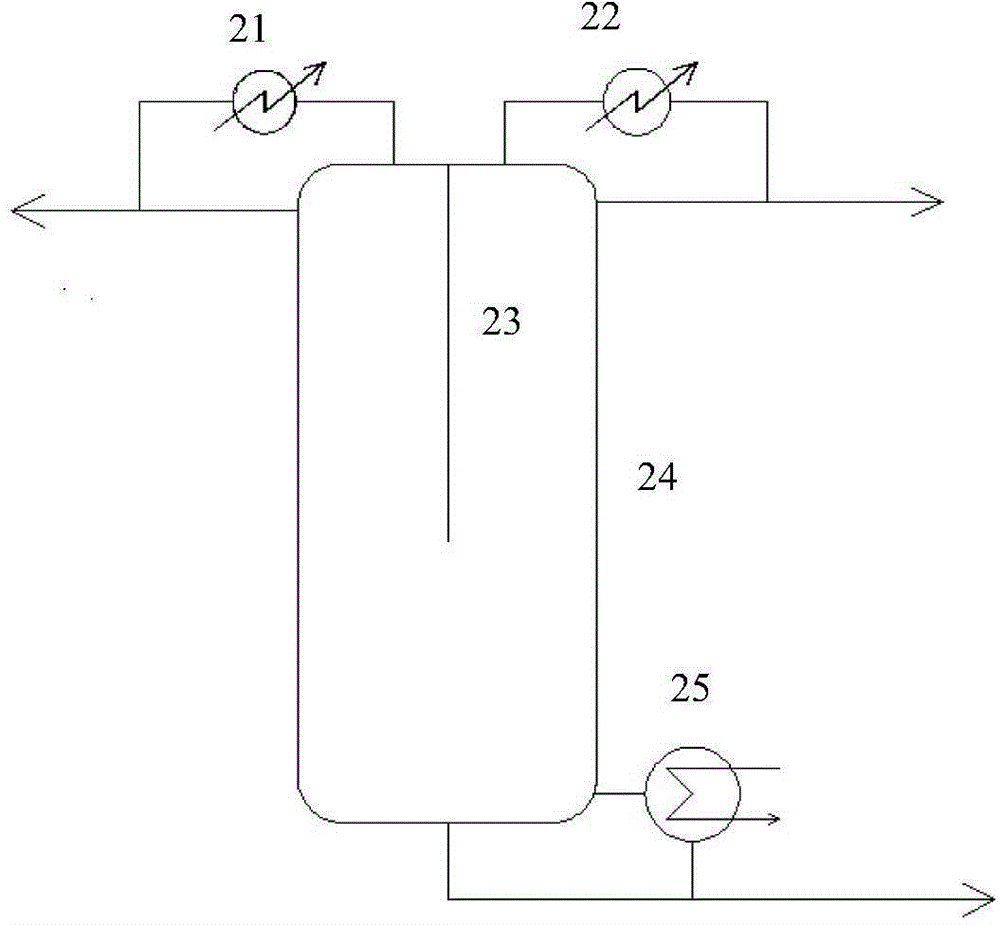

Image

Examples

Embodiment 1

[0056] Natural gas molar composition 1.54% N 2 , 86.39%CH 4 , 6.47%C 2 h 6 , 2.87%C 3 h 8 , 0.72% i-C 4 h 10 , 0.82% n-C 4 h 10 , 0.41% i-C 5 h 12 , 0.31% n-C 5 h 12 , 0.31% n-C 6 h 14 , 0.16% C7+, pressure 4.9MPa, temperature 35°C, flow 1.512*10 4 kgmol / h, the specific steps of the skid-mounted nitrogen expansion natural gas liquefaction and NGL recovery process are as follows:

[0057] 1. Raw natural gas enters the demethanizer 1 for rectification, and heavy hydrocarbons are obtained from the bottom with a temperature of 84.95°C and a pressure of 4.9MPa, and natural gas is obtained from the top with a temperature of -78.24°C and a pressure of 4.89MPa;

[0058] 2. The heavy hydrocarbons obtained in step 1 enter the TDWC synthesis tower 2 for rectification, and obtain C from the bottom 5+ , the temperature is 166.7°C, the pressure is 2.11MPa, and the top end gets C 1 、C 2 、C 3 , the temperature is 6.142℃, the pressure is 2.725MPa, and the other end gets C 3...

Embodiment 2

[0068] Example 2 (for the associated gas source of an offshore oilfield in the South my country Sea):

[0069] Natural gas molar composition 1.1% N 2 , 90.9%CH 4 , 4.2%C 2 h 6 , 1.6%C 3 h 8 , 0.4% i-C 4 h 10 , 0.4% n-C 4 h 10 , 0.2% i-C 5 h 12 , 0.1% n-C 5 h 12 , 0.2% n-C 6 h 14 , 0.9%C 7+ , pressure 5MPa, temperature 40°C, flow rate 20*10 4 N m 3 / d, the specific steps of the skid-mounted nitrogen expansion natural gas liquefaction and NGL recovery process are as follows:

[0070] 1. Raw natural gas enters the demethanizer 1 for rectification, and heavy hydrocarbons are obtained from the bottom with a temperature of 136.8°C and a pressure of 4.9MPa, and natural gas is obtained from the top with a temperature of -74.73°C and a pressure of 4.89MPa;

[0071] 2. The heavy hydrocarbons obtained in step 1 enter the TDWC synthesis tower 2 for rectification, and obtain C from the bottom 5+ , the temperature is 195.3°C, the pressure is 2.11MPa, and the top end get...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com