Highly-stable anticorrosion complete set heat supply system

A heating system and a complete set of technology, applied in the energy field, can solve problems such as hydraulic imbalance, reduce debugging difficulty, low temperature corrosion, etc., and achieve the effect of adapting to dynamic changes and improving hydraulic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Concrete structure of the present invention is referring to accompanying drawing. The accompanying drawings are provided only for better understanding of the present invention, and they should not be construed as limiting the present invention.

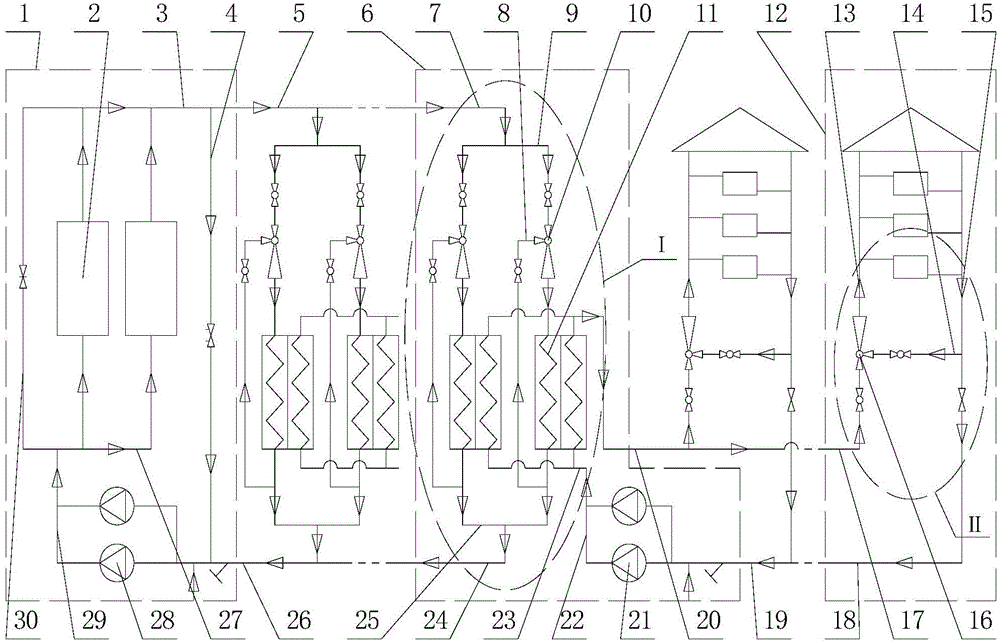

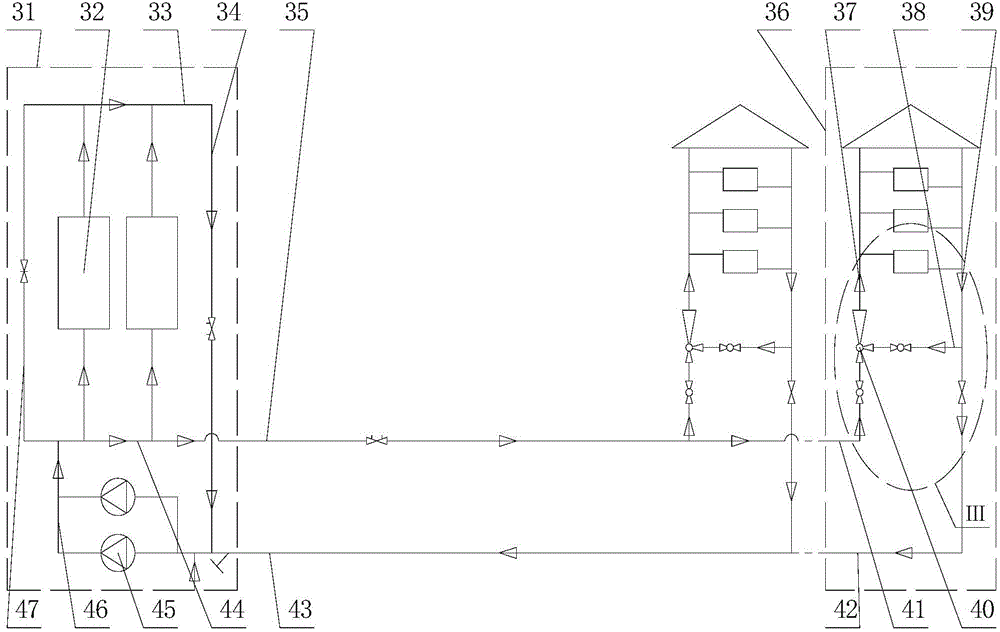

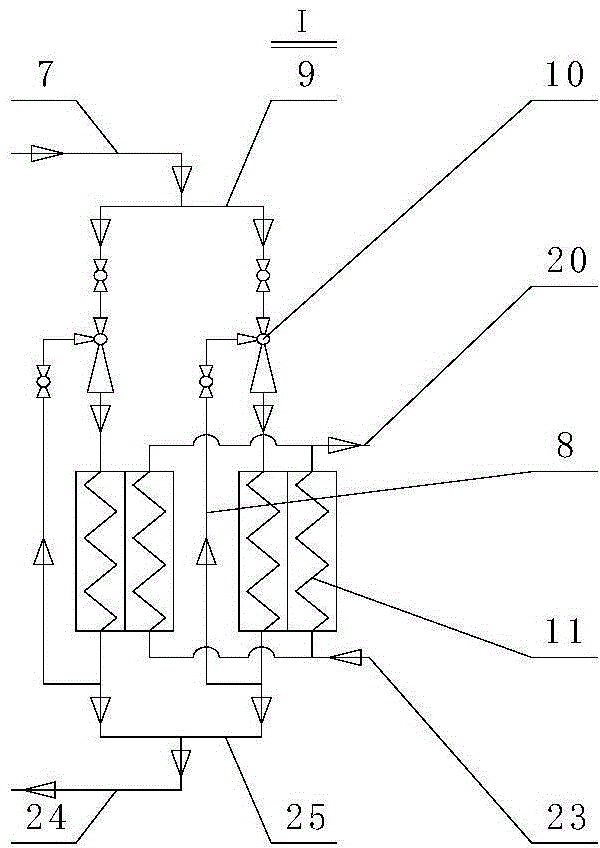

[0085] see figure 1 , 3 4. The structure of the high-stable anti-corrosion complete heating system shown in 4, the left side is the schematic diagram of the primary system, and the right side is the secondary system. For the primary supply system, jet pumps (10) are installed on the primary side of each heat exchange station to form a composite heat exchange unit (I) with the heat exchanger (11). Using the self-priming function of the jet pump (10), it will Part of the primary return water is sucked into the primary water supply pipe, mixed with the primary water supply, and then enters the heat exchanger (11). 1) Converging to form a "primary main cycle", install an anti-corrosion water mixing pipe (4) between the boiler ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com