Heat supply system for adjustable jet pumps

A heating system and jet pump technology, applied in the field of regulating systems, can solve problems such as difficult debugging and unsatisfactory results, and achieve the effects of simple debugging, increased resistance, and reduced operating flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

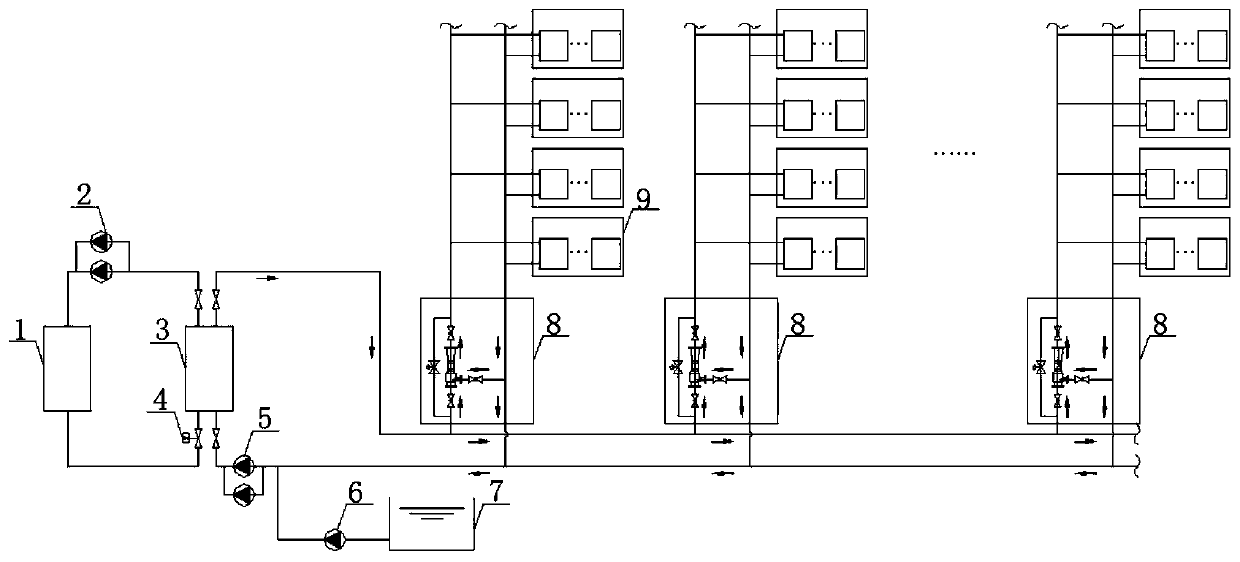

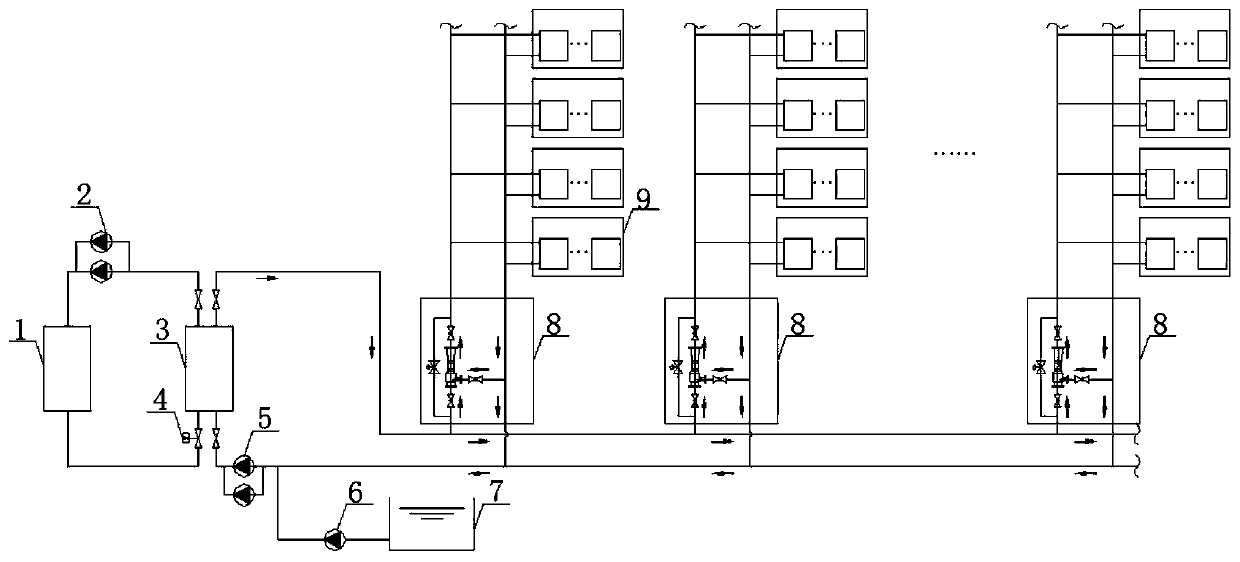

[0010] An adjustable jet pump heating system according to the present invention is composed of the following parts: heat source plant or boiler 1, primary network circulation pump 2, plate heat exchanger 3, electric control valve 4, secondary network circulation pump 5, Supplementary water pump 6, supplementary water tank 7, adjustable jet pump device 8, heat user 9.

[0011] see figure 1 As shown, the heat source plant or boiler 1, the electric regulating valve 4 and the primary circulation pump 2 are connected in series on one side of the plate heat exchanger 3 to form a primary circulation pipeline; the other side of the plate heat exchanger 3 is connected in series with two The secondary circulation pipeline composed of the secondary network circulation pump 5 and the heat user 9; an adjustable jet pump 8 is installed in front of each heat user 9.

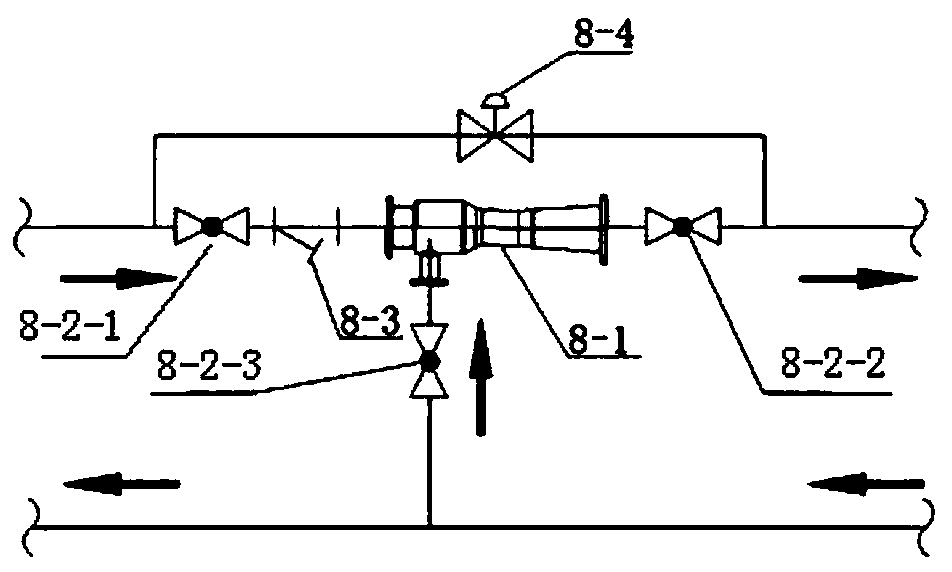

[0012] see figure 2 As shown, the adjustable jet pump consists of the following parts: jet pump 8-1, three ball valves 8-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com