Hooping apparatus for concrete column construction joints

A technology of concrete columns and construction joints, which is applied in the fields of formwork/formwork/work frame, on-site preparation of building components, construction, etc., to achieve the effect of ensuring implementation accuracy, tight gap sealing, and not easy to swing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

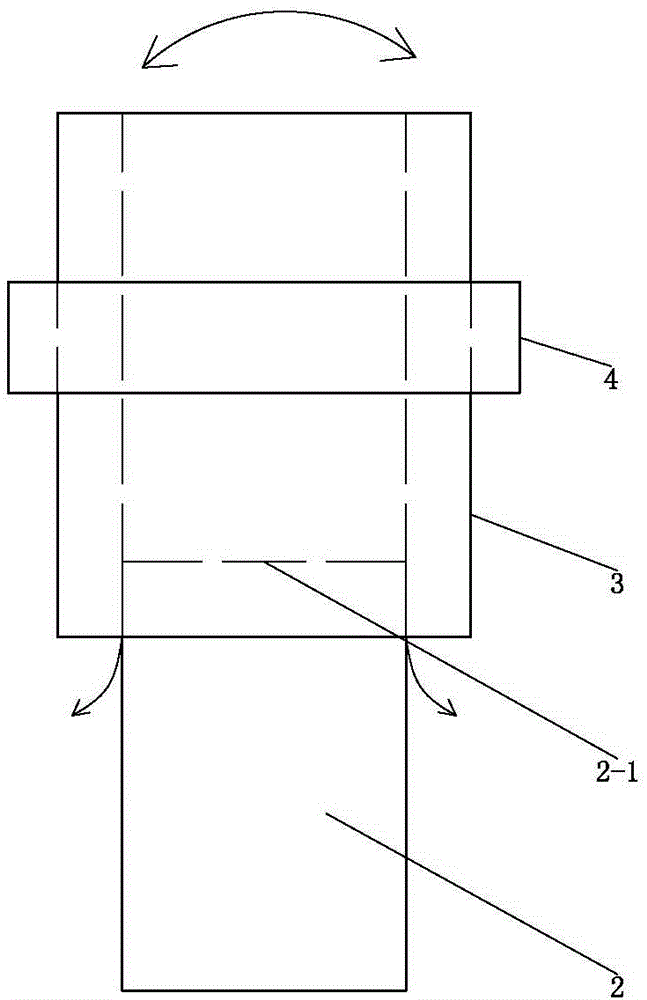

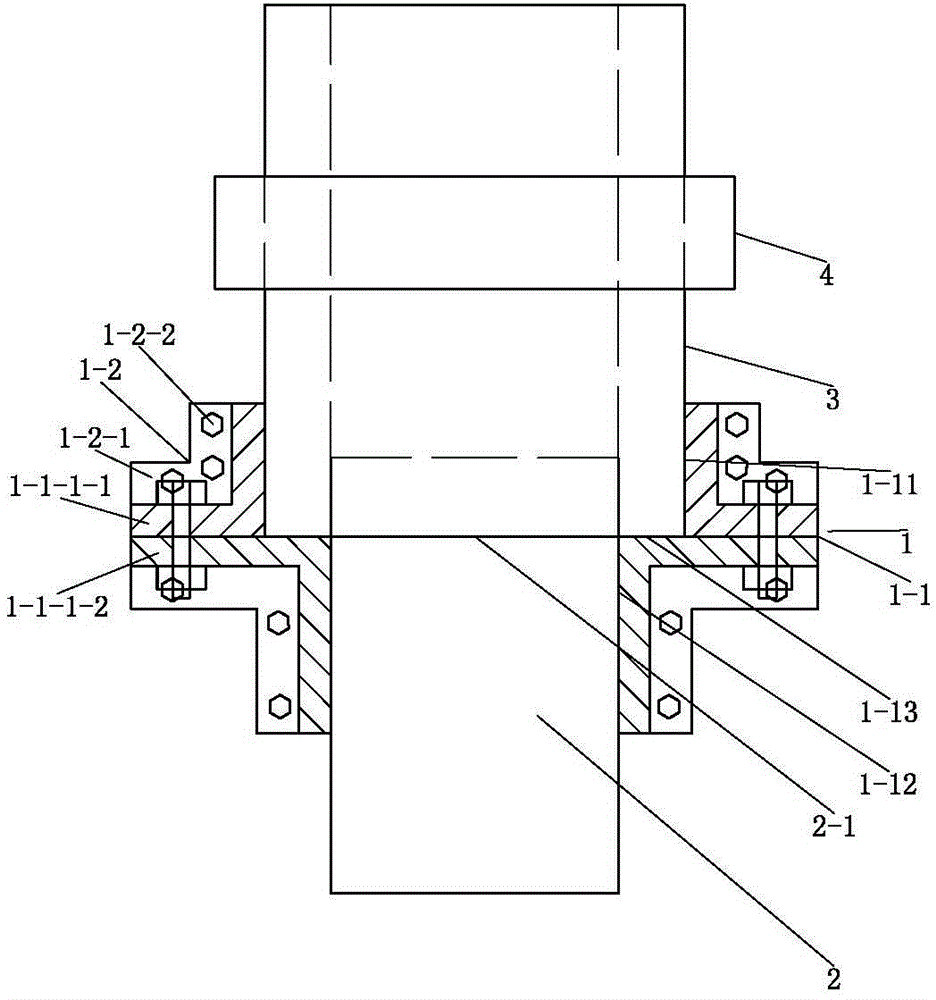

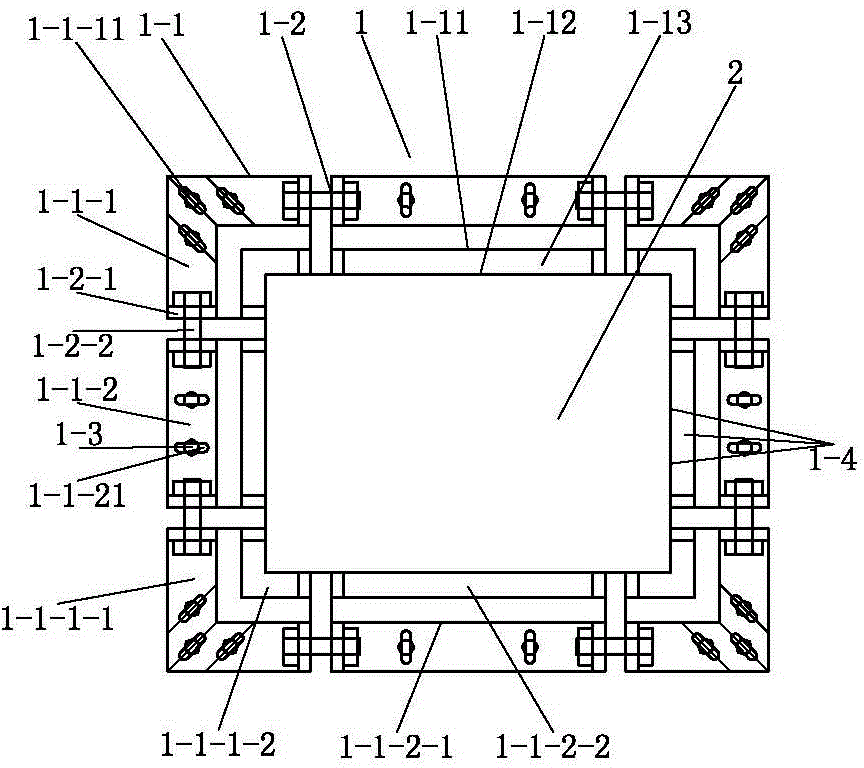

[0060] Such as Figure 2 to Figure 6 As shown, this embodiment provides a tightening device 1 at the construction joint of a concrete column, including a tightening ring 1-1, and the tightening ring 1-1 has a cylindrical formwork tightening surface for tightening the formwork 3 1-11, the cylindrical template hoop surface 1-11 used to clamp the template 3 is a cylindrical template hoop surface 1-11 used to clamp the lower end side of the template 3, the cylindrical template hoop surface The lower end edge of 1-11 shrinks inwardly to form an annular template supporting surface 1-13 for supporting the lower end surface of the template 3. The width of the annular template support surface 1-13 is adapted to the thickness of the template 3. The annular template The inner edge of the supporting surface 1-13 extends downward to form a columnar concrete column clamping surface 1-12 for clamping the upper end side of the concrete column 2.

[0061] In this embodiment, the cylindrical templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com