A construction quality inspection method for vertical composite water-stop curtain body

A technology of water-stop curtain and construction quality, which is applied in the direction of basic structure engineering, basic structure test, construction, etc. It can solve the problems of improper drilling core operation, high drilling cost, low cement soil strength, etc., and achieve high working frequency, The effect of high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

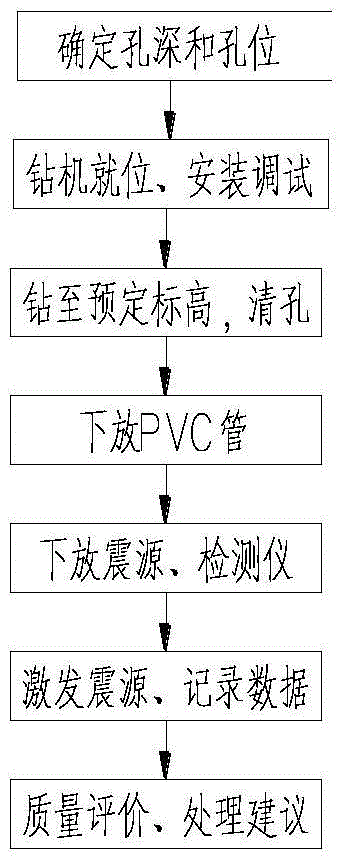

[0044] figure 1 It is the construction process flow chart of the construction quality inspection method of the direct composite water-stop curtain body. First conduct site survey to determine the hole position and depth of the test hole, then place the drilling rig in place, install and debug, then drill the hole to the predetermined elevation, clean the hole, then lower the PVC pipe in the test hole, and then place the vibration source and detector , then excite the source, record the data, and finally combine the data into four grades for quality evaluation, and give corresponding processing suggestions according to the four grades.

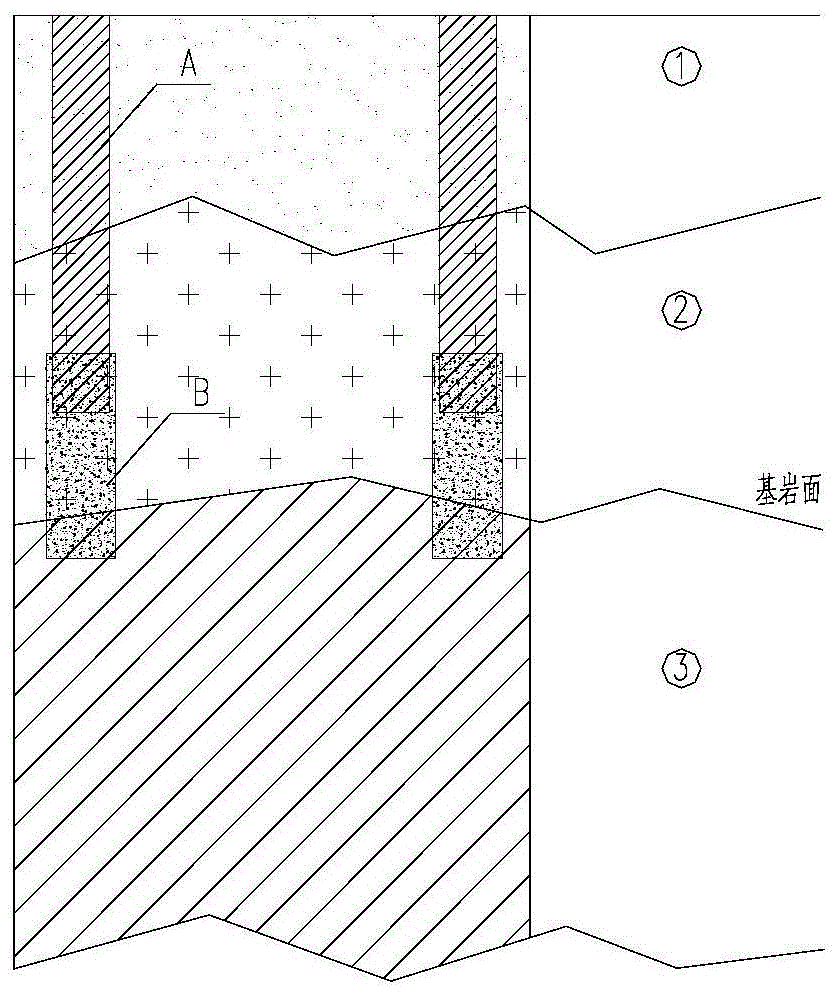

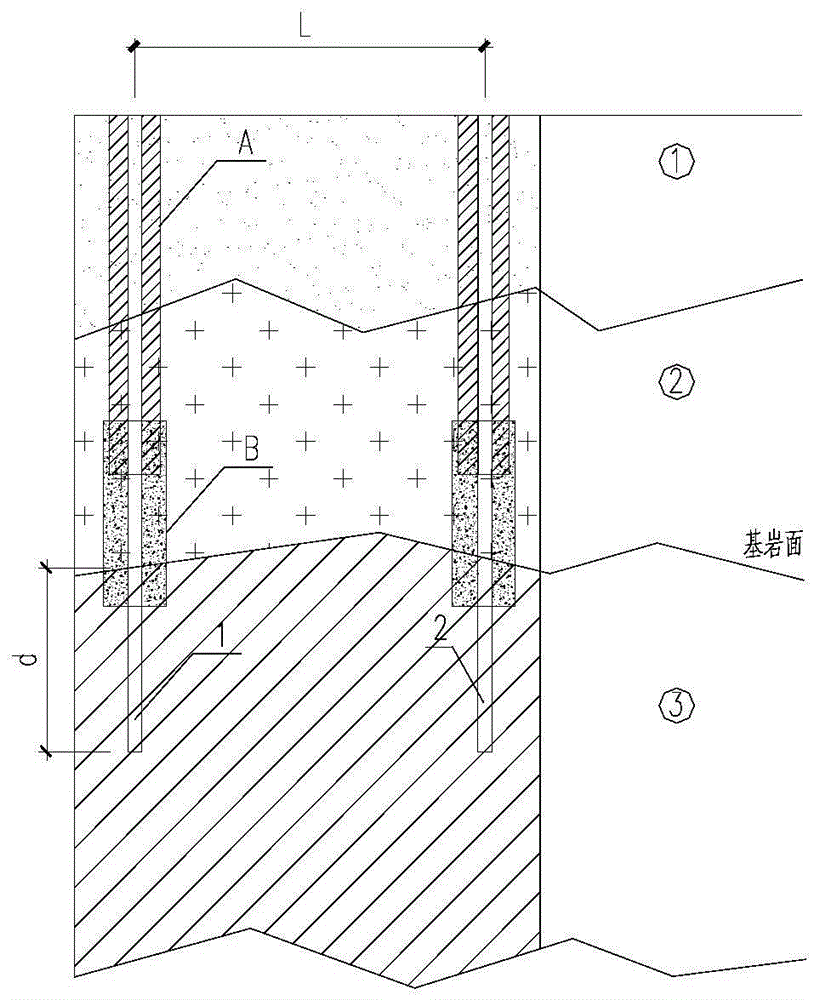

[0045] Please refer to Figure 2 to Figure 5 , the vertical composite water-stop curtain body is composed of a single row of φ850@1200 three-axis mixing piles above the bedrock surface, and a single row of φ900@600 high-pressure jet grouting piles concentric with the three-axis mixing piles and embedded in the bedrock. The two piles overlap 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com