A cone-wedge active device and construction method for internal support in foundation pit engineering

A cone-wedge and flexible technology, which is applied in basic structure engineering, excavation, construction, etc., can solve problems such as poor integrity and unreliable force transmission, and achieve the effect of reasonable structure, significant comprehensive benefits, and integrity assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

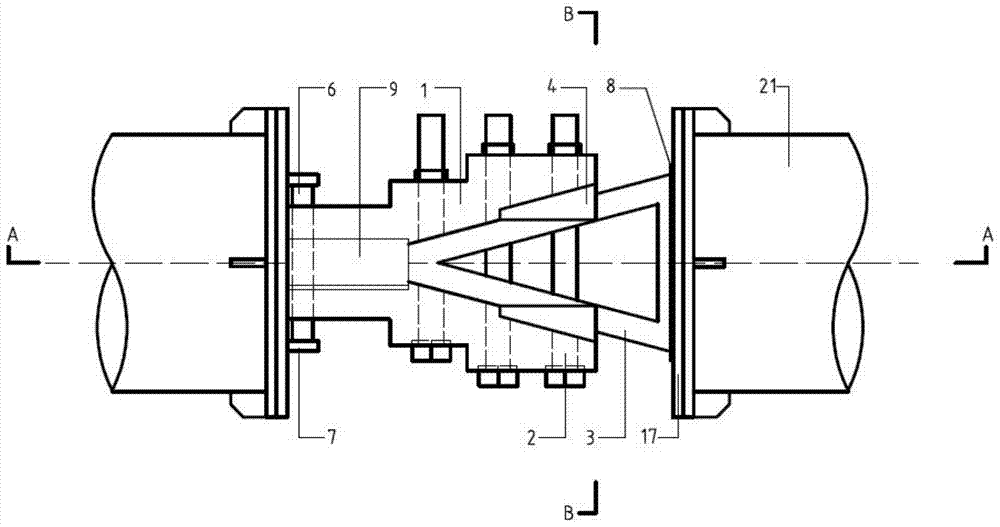

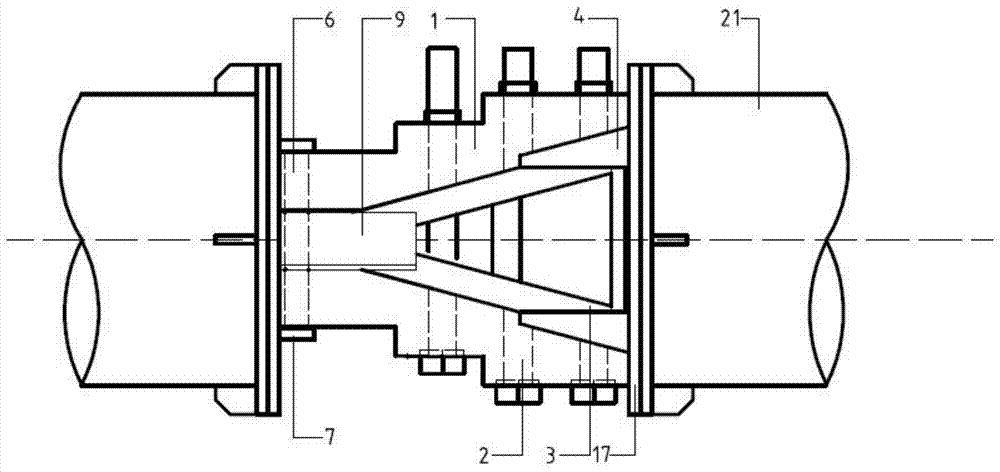

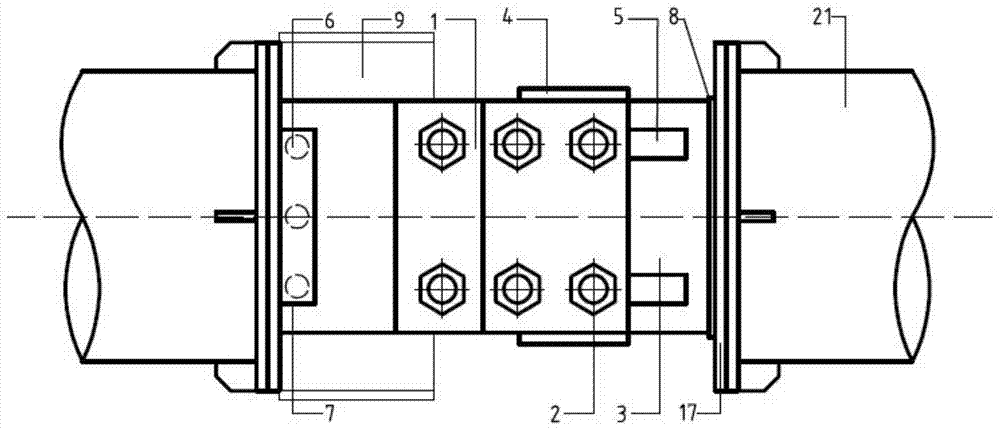

[0040] Through the following example, such as Figure 1-15 Shown, the present invention is further described.

[0041] Design description, a cone-wedge active device of the present invention used for support in foundation pit engineering, the maximum axial force of the steel support is designed to be 2900kN, and the safety factor is considered to be 1.2 to provide a certain safety reserve to prevent accidental loads and formation deformation Accidents such as excessively large accidents cause engineering accidents.

[0042] A cone-wedge movable device for internal support in foundation pit engineering includes a splint 1, high-strength bolts 2, conical outriggers 3, a railing 4, a fixed round rod 6 and a fixed baffle 7; the splint 1 is mainly made of thick-walled steel plates 18 is composed of flange 17 and jack pallet 9. The thick-walled steel plate 18 of splint 1 is connected through screw hole 19, fixed round rod 6 and fixed baffle 7; fixed baffle 7 is welded on flange 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com