A pile head crushing device

A crushing device and pile head technology, which is applied in the direction of sheet pile walls, buildings, foundation structure engineering, etc., can solve the problems of difficult operation, high labor intensity, and inability to meet pile heads of different diameters, and achieve the effect of wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

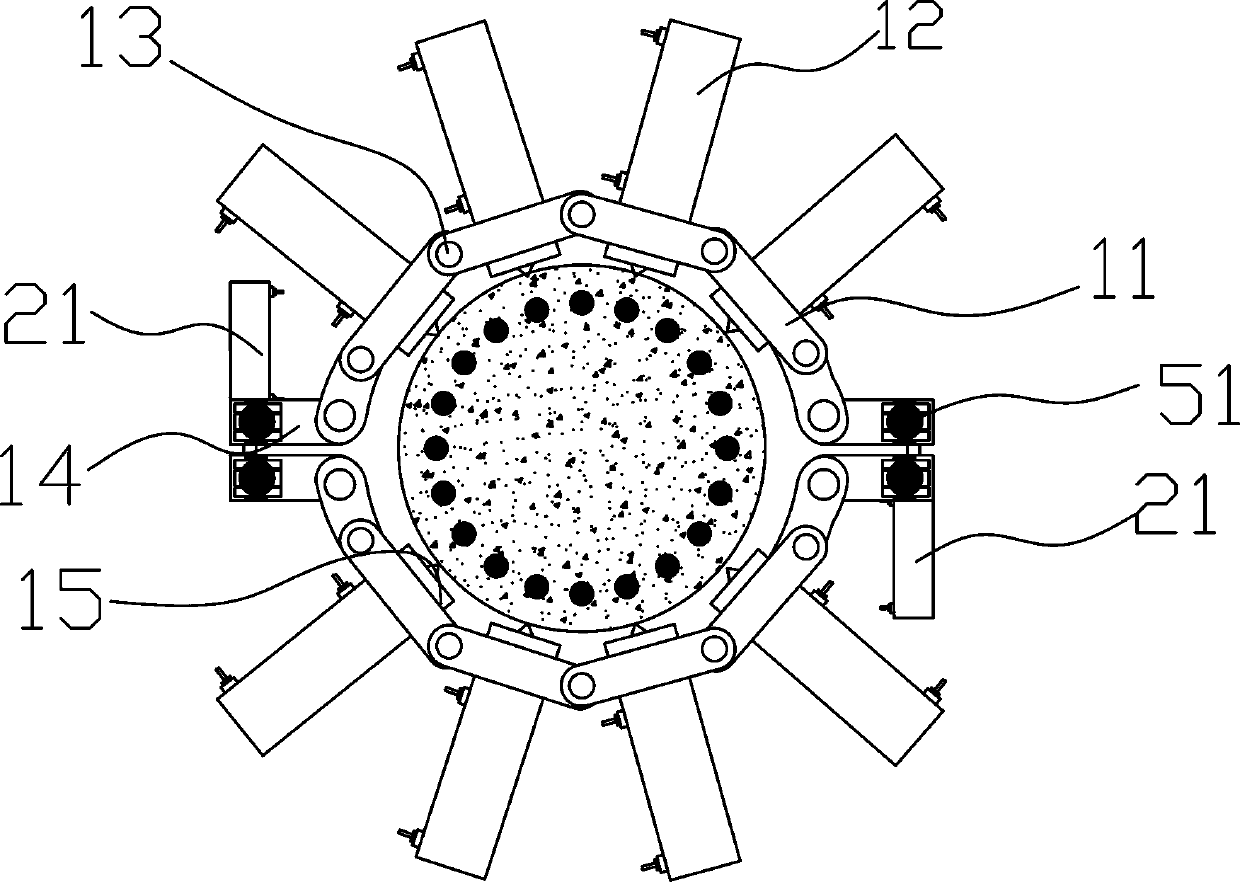

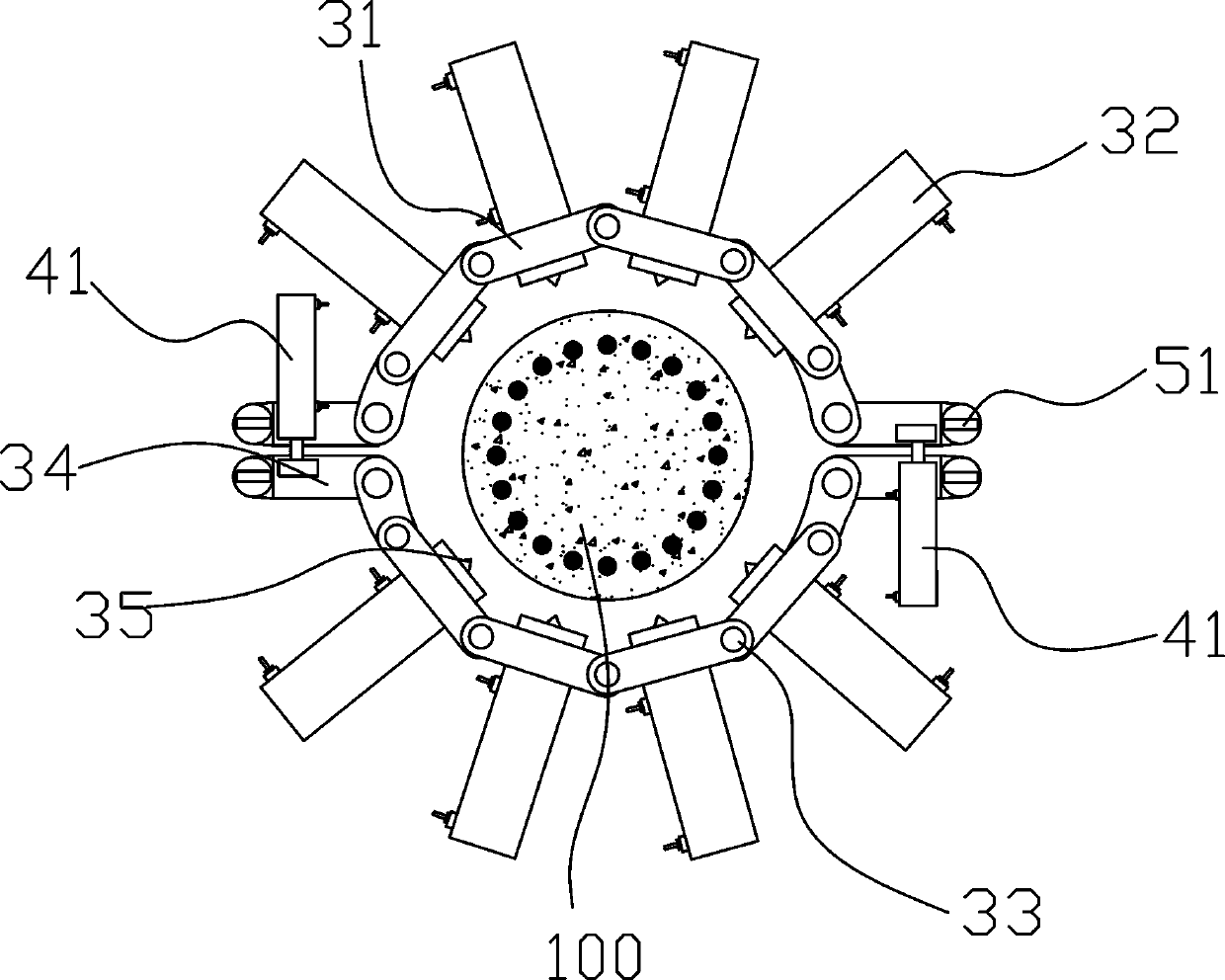

[0020] The following is attached Figure 1-3 The present invention is further described in detail.

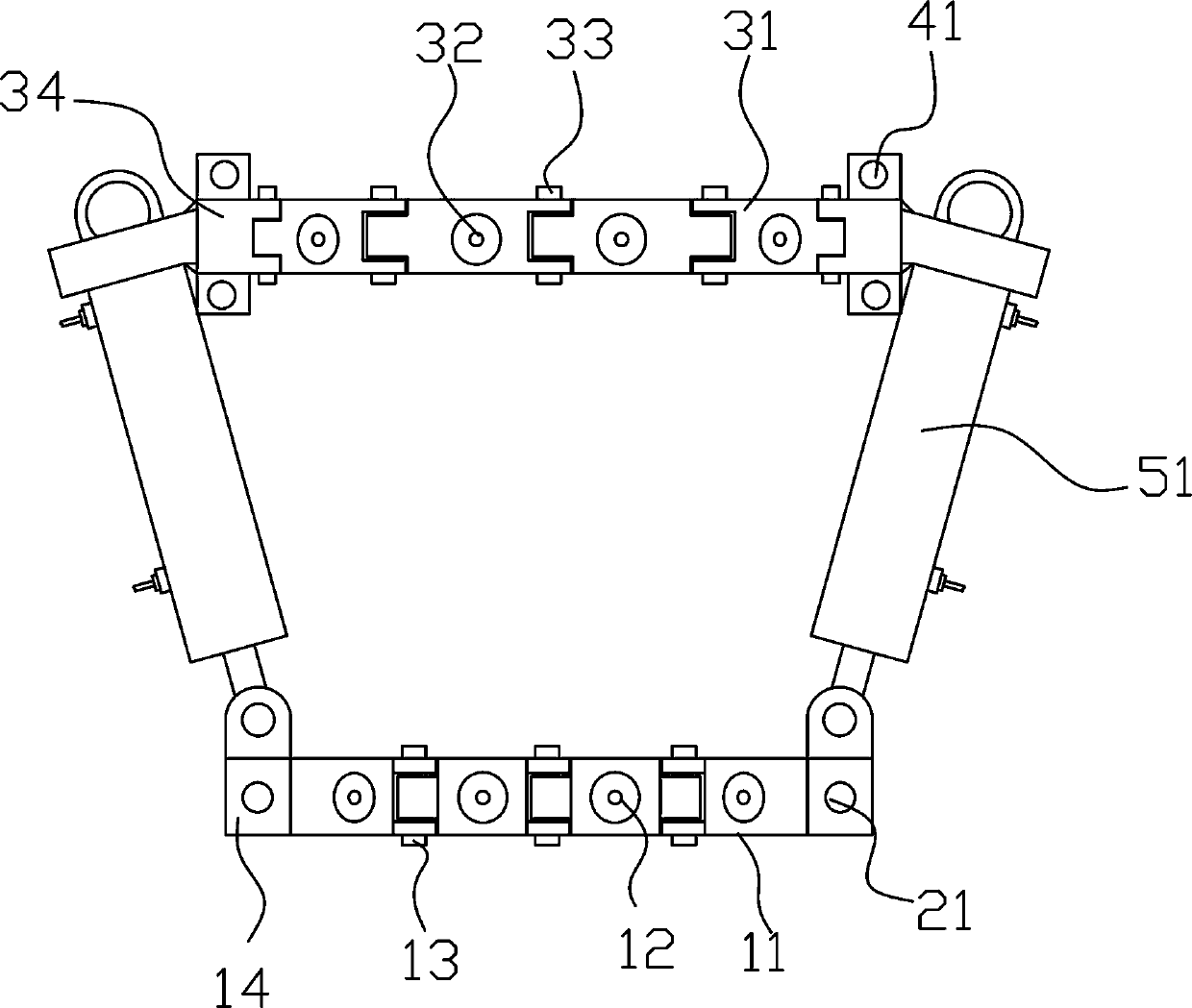

[0021] as attached figure 1 , 2 As shown in and 3, a pile head crushing device includes a lower positioning crushing mechanism, an upper crushing mechanism and a telescopic connector arranged between the lower positioning crushing mechanism and the upper crushing mechanism;

[0022] The lower positioning crushing mechanism is composed of two semicircular lower crushing assemblies butted together. The lower crushing assembly includes eight lower crushing units connected to each other. The lower crushing units include a lower mounting frame 11 fixedly arranged on the lower The lower hydraulic cylinder 12 on the mounting frame 11 and the lower crushing head 15 arranged at the top of the piston of the lower hydraulic cylinder 12; the two ends of the lower mounting frame 11 are provided with lower connection holes, and the two adjacent lower crushing units Connected by the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com