Purification process of methionine

A methionine and process technology, which is applied in the field of methionine purification process, can solve problems affecting product quality and yield, environmental secondary pollution, and accompanying precipitation of salt substances, etc., to simplify the production process, improve product quality, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

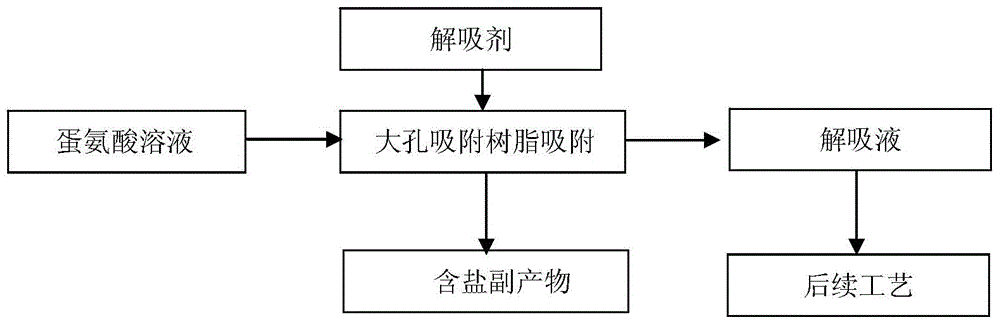

Method used

Image

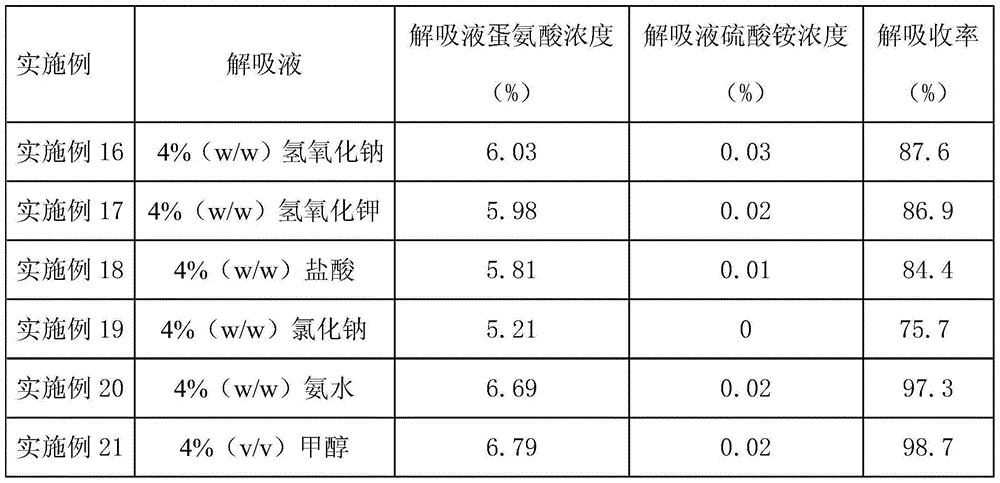

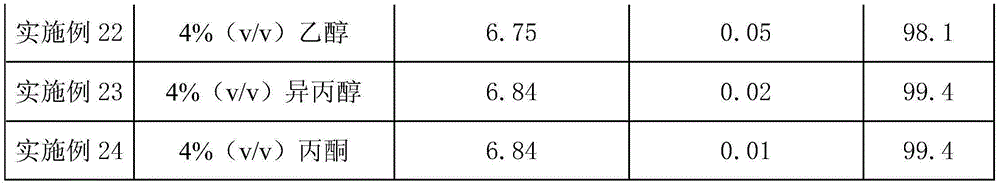

Examples

Embodiment 1

[0031] 1. Resin adsorption: Pass methionine solution (pH: 10.72, methionine content 17.24% (w / w), sodium carbonate content 10.35% (w / w)) through 100ml XDA- 1 Resin bed (produced by Xi'an Lanxiao Technology New Material Co., Ltd.), collect the resin effluent separately, and stop feeding into the resin column when the methionine content in the effluent at the bottom of the resin column is 1.7%.

[0032] 2. Resin desorption: 2BV of 3% sodium hydroxide solution desorbs the resin from top to bottom at a flow rate of 1BV / h, and collects the desorption solution.

[0033] 3. Collect 300 ml of resin effluent, and detect that the content of methionine is 0.02%, and the content of sodium carbonate is 10.35%. 200ml of the desorption solution was collected, the content of methionine was detected to be 24.60%, and the yield of methionine was 95.15%.

Embodiment 2

[0035] 1. Resin adsorption: adjust the pH of the liquid methionine solution to 2.2 with 2% sulfuric acid solution (the content of methionine is 2.8% (w / w), the content of potassium sulfate is 17.4% (w / w)), and the flow rate is 1BV / h from top to bottom Pass through a 100ml XDA-8 resin bed (produced by Xi'an Lanxiao Technology New Materials Co., Ltd.) at a lower uniform speed, collect the resin effluent separately, and stop feeding to the resin column when the methionine content in the effluent at the bottom of the resin column is 0.3%.

[0036] 2. Resin desorption: 3BV of 4% methanol solution desorbs the resin from top to bottom at a flow rate of 1BV / h, and collects the desorption solution.

[0037] 3. Collect 700 ml of resin effluent, and detect that the content of methionine is 0.01%, and the content of potassium sulfate is 17.38%. 302ml of the desorption solution was collected, the content of methionine was detected to be 6.45%, and the yield of methionine was 98.76%.

Embodiment 3- Embodiment 9

[0039] The specific embodiment is the same as that in Example 1, mainly investigating the influence of methionine solutions with different pH on the adsorption capacity of the resin. (Not stated in the experiment are all mass percentage concentrations)

[0040] Methionine content: 2.80%, ammonium sulfate content 43.5%, potassium carbonate content 2.1%. Feed volume 7BV, feed flow rate 1BV / h, prepare 5 parts of XDA-1 resin, each 100ml resin. The methionine solution was adjusted to pH 1.0, 3.0, 7.0, 9.0, 10.0 with 4% sodium hydroxide or 4% sulfuric acid solution respectively, and the adsorption control test was carried out.

[0041] Resin adsorption capacity = (feed methionine content * feed volume - effluent methionine content * effluent volume) / resin volume

[0042] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com