Movable rear paper-neatening device adapted to various types of paper sizes

A technology of paper and specifications, applied in the field of paper finishers, can solve the problems of paper size requirements and the inability to cut 750mm paper, and achieve the effect of low cost, simple structure, and meeting the requirements of paper size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

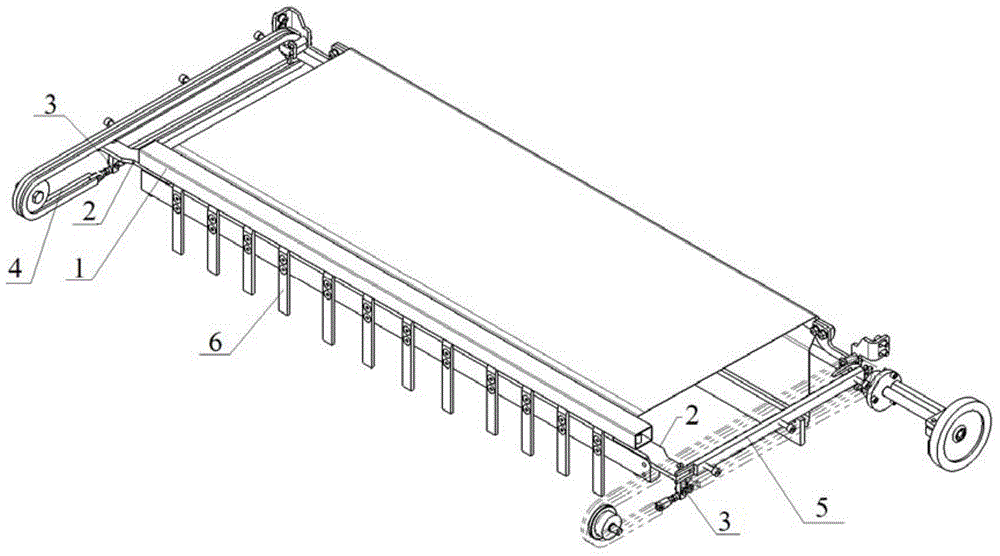

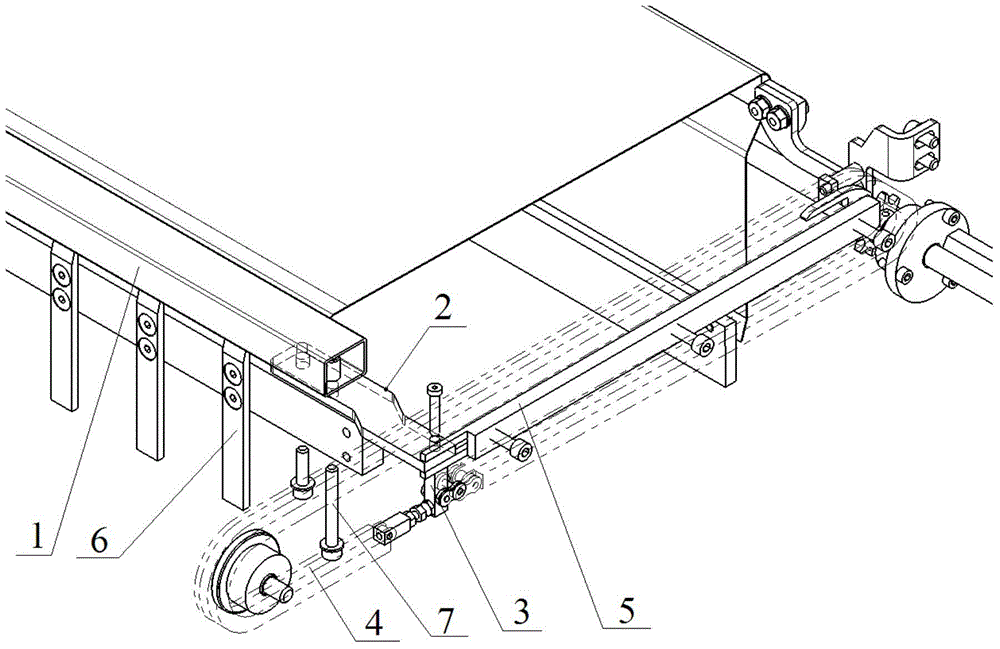

[0023] A finisher that is movable to accommodate various paper sizes, such as figure 1 , figure 2 As shown, the rear trimmer, the front trimmer, the left trimmer and the right trimmer form the delivery part of the die-cutting machine, which is used to receive the stacking and ordering of the paper after die-cutting. The rear trimmer includes longitudinal Beam 1, support plate 2, moving block 3, chain 4, crossbeam 5 and whole paper fence 6, chain 4 is provided with two, is respectively arranged on the both sides of longitudinal beam 1, and crossbeam 5 is provided with two, is arranged in parallel respectively Above the two chains 4, there are two moving blocks 3, which are respectively connected to the middle sections of the two chains 4 and move with the movement of the chains 4. There are two support plates 2, and the inner end of the support plate 2 is connected to the longitudinal beam. The ends of 1 are connected, the outer end of support plate 2 is connected with moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com