High-structural-strength three-dimensional solid wood composite board and forming method thereof

A high-structure, composite panel technology, which is applied in the jointing of wooden veneers, chemical instruments and methods, and wood layered products, can solve problems such as difficulty in maintaining consistency, inability of panels to bear loads, and inconvenience in practical application, and achieve reduction Thickness, improved load-bearing capacity, and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

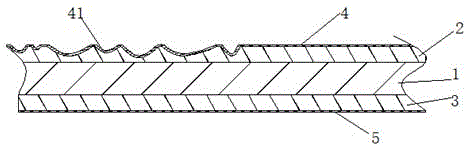

[0043] The present embodiment provides a kind of three-dimensional solid wood composite panel with high structural strength, such as figure 1 , including a hard base layer 1, and a first capacity layer group 2 and a second capacity layer group 3 arranged on both sides of the base layer; a flexible capacity layer is respectively arranged in the first capacity layer group and the second capacity layer group; It includes a surface layer 4 arranged on the surface of the first capacity layer.

[0044] In this embodiment, the above-mentioned hard base layer is a commercially available Ozon board. The flexible capacity layer is pine wood. Natural wood veneer for the finish.

[0045] Further, the thickness of the surface layer 4 is 1 mm, the thickness of the first capacity layer is 1 mm, the thickness of the second capacity layer group is 1.2 mm, and the thickness of the base layer is 25 mm.

[0046] Further, the surface layer is provided with a decorative groove 41, and the bottom...

Embodiment 2

[0051] Such as figure 2 , the present embodiment provides the preparation method of embodiment 1 high structural strength three-dimensional solid wood composite board, specifically as follows:

[0052] a. Polish the Ozon board, 1, and apply glue on both sides of the Ozon board;

[0053] b. Paste a layer of pine board 2 and pine board 3 on both sides of the European pine board;

[0054] c. coating glue on the surface of one of the pine boards 2;

[0055] d. Paste one deck of natural veneer 4 on the surface of above-mentioned pine board 2;

[0056] e. Heat the above plate to 101°C under 6MP high pressure and keep it for 9 minutes;

[0057] f. Cold pressing the above plate at 5°C for 16 minutes to obtain a semi-finished plate;

[0058] g. Using a mold with embossed lines, press the semi-finished board under a pressure of 13 MP for 5 minutes to obtain the high structural strength three-dimensional solid wood composite board of this embodiment.

Embodiment 3

[0060] The present embodiment provides a kind of three-dimensional solid wood composite panel with high structural strength, such as image 3 , including a hard base 1, and a first capacity layer group 2 and a second capacity layer group 3 arranged on both sides of the base layer; a flexible capacity layer is respectively arranged in the first capacity layer group and the second capacity layer group; It includes a surface layer 4 arranged on the surface of the first capacity layer.

[0061] In this embodiment, the hard base layer is a reconstituted board. The capacity layer is poplar board.

[0062] Further, the thickness of the surface layer is 2 mm, the thickness of the first capacity layer is 5 mm, the thickness of the second capacity layer group is 5 mm, and the thickness of the base layer is 31 mm.

[0063] The surface layer is provided with a decorative groove 41, and the bottom of the decorative groove is embedded in the first capacity layer group.

[0064] The ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com