Vibration polishing machine

A technology of polishing machine and motor components, which is applied in surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding the edge of workpieces, etc. Unsatisfactory and other problems, to achieve the effect of cost saving, good polishing effect and fast vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It is easy to understand that, according to the technical solution of the present invention, those skilled in the art can imagine various implementations of the vibration polishing machine of the present invention without changing the essence and spirit of the present invention. Therefore, the following specific embodiments and drawings are only exemplary descriptions of the technical solution of the present invention, and should not be regarded as the entirety of the present invention or as a limitation or limitation on the technical solution of the present invention.

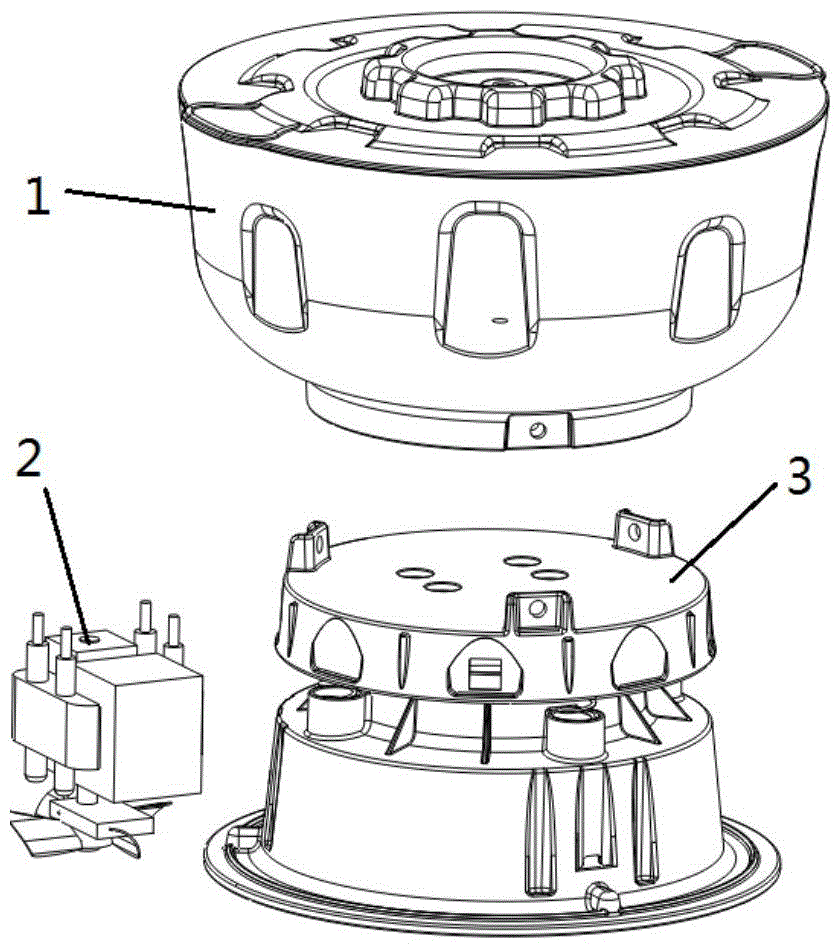

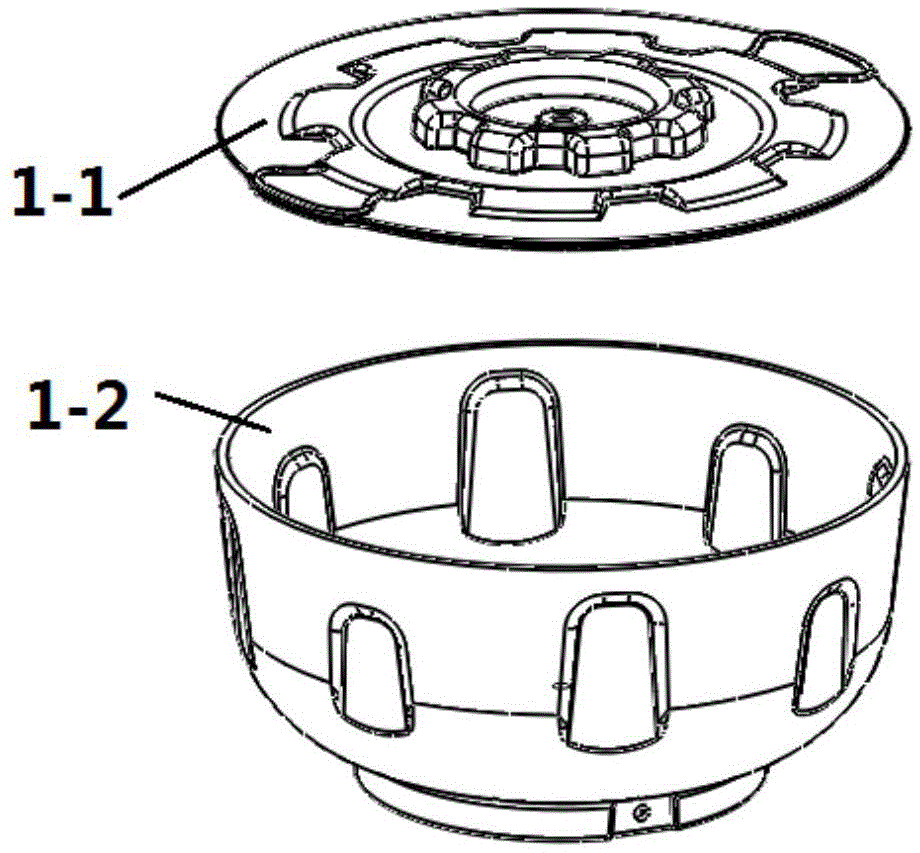

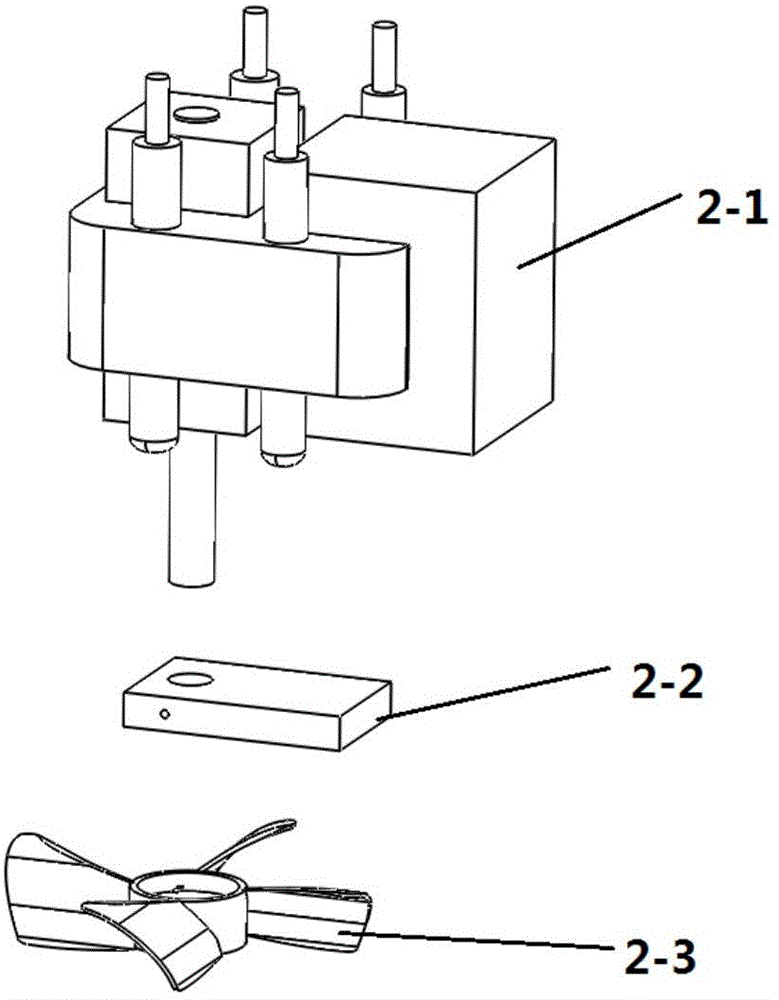

[0024] The vibration polishing machine of the present invention comprises: a vibration bowl assembly 1; a motor assembly 2; a base assembly 3;

[0025] The base assembly 3 is used to support the vibration bowl assembly 1 and install the motor assembly 2; it includes: a motor mounting support 3-1, a spring 3-2, and a base 3-3; the motor mounting support 3-1 is used to install the motor assembly 2 , the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com