Machine tool with lubricating oil recycling function

A lubricating oil and function technology, applied in the field of machine tools with lubricating oil recovery function, can solve problems such as environmental damage, save lubricating oil costs, improve recovery efficiency, and solve the effect of waste oil discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

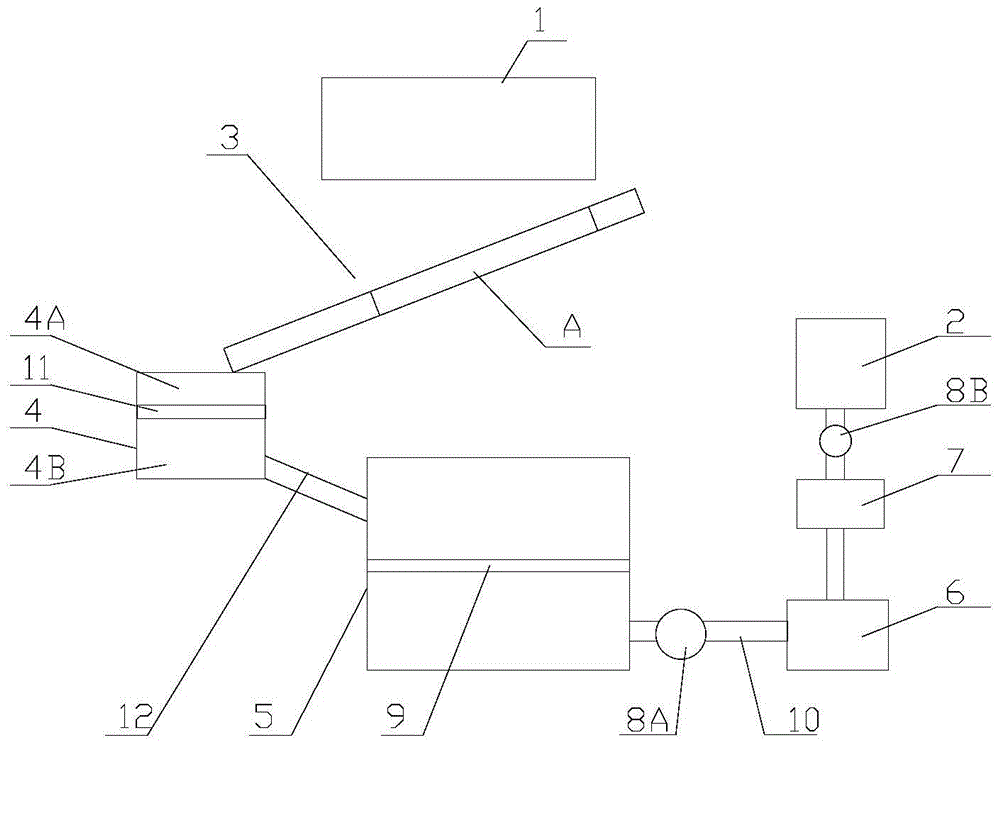

[0015] refer to figure 1 , a kind of machine tool with lubricating oil recovery function that the present invention proposes, comprises: frame, processing mechanism 1, oil storage tank 2, oil residue separating sieve plate 3, slag collecting box 4, oil collecting box 5, lubricating oil filter 6, Recovery tank 7, first suction pump 8A, and second suction pump 8B.

[0016] The processing mechanism 1 is installed on the frame for processing workpieces, and the oil storage tank 2 can provide lubricating oil to the processing mechanism 1 to lubricate parts.

[0017] The oil residue separation sieve plate 3 is obliquely installed on the frame and is located directly below the processing mechanism 1. There are multiple sieve holes on the oil residue separation sieve plate 3, and the area where the oil residue separation sieve plate 3 is equipped with sieve holes forms a filtering area. a.

[0018] The oil collection tank 5 is installed on the side of the oil residue separation siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com