Natural plant stabilizer for beverage products as well as formulation method and application of natural plant stabilizer

A natural plant and stabilizer technology, used in food ingredients as clouding agents, food science, polysaccharide/gum-containing food ingredients, etc., can solve food safety doubts or panic problems, and achieve improved taste and flavor, unique flavor, prolonged shelf life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

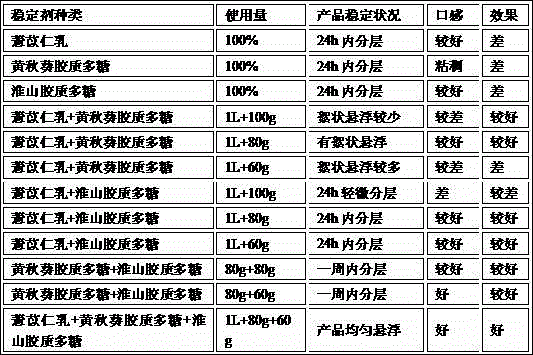

Method used

Image

Examples

Embodiment 1

[0039] According to Scheme 1: 1L Coix seed milk added 80g gum okra polysaccharide and 60g yam yam gum as the reference ratio. Take 25ml of concentrated coix seed milk, 2g of okra gum polysaccharide, and 1.5g of yam yam polysaccharide, the powder fineness of the components is 200 mesh, and the solid content of concentrated coix seed milk is 30%.

[0040] Preparation of concentrated Coix Seed Milk:

[0041] (1) Baking: Baking the coix seed moderately to produce a strong fragrance, the baking temperature is 150~180℃, and the time is 10~15 min;

[0042] (2) Soaking: The volume ratio of material to water during soaking is 1:3, and 0.5% NaHCO is added according to the volume ratio of 1:100 3 Soak in the solution at room temperature for 6-10 hours until the Coix seed is soft, drain and set aside;

[0043] (3) Refining: The volume ratio of grinding slurry to water is 1:6, and it is separated by filtering through a 100-mesh sieve;

[0044] (4) Heating up: heating the liquid material after sievi...

Embodiment 2

[0071] According to the scheme 1: 1L concentrated coix seed milk added with 120g okra gum polysaccharide and yam yam gum 80g as the reference ratio. Take 30ml concentrated coix seed milk, 3.6g okra gum polysaccharide, 2.4g yam yam polysaccharide, the powder fineness of the components is 200 mesh, and the solid content of concentrated coix seed milk is 30%.

[0072] The preparation method of natural plant stabilizer for beverage products includes the following steps:

[0073] (1) Mixing and preparation: take the materials of the proportioning components of claim 1 and mix them evenly;

[0074] (2) Degassing: Use a vacuum degasser to degas the mixture at a temperature of 45°C and a vacuum of 93.5 k Pa;

[0075] (3) Homogenization: The degassed mixture is heated to 65~85℃ for partial homogenization, the first homogenization pressure is 20-30MPa, and the second homogenization pressure is 30-40MPa;

[0076] (4) Sterilization and cooling: use pasteurization to heat the mixture to 68~70℃ and ...

Embodiment 3

[0082] According to the second plan: take L concentrated coix seed milk, 2L concentrated buckwheat saccharification liquid, 1L concentrated corn juice mixture, and add 200g okra gum polysaccharide and 150g yam gum polysaccharide according to 1L mixture as the reference ratio. Take 30ml concentrated coix seed milk, 30ml concentrated buckwheat saccharification liquid, 15ml concentrated corn juice, 15g okra gum polysaccharide, 11.2g yam gum polysaccharide, the powder fineness of the components is 200 mesh, and the solid content of concentrated coix seed milk is 30 %, the solid content of concentrated corn juice is 40%, and the sugar content of concentrated buckwheat saccharification liquid is 20

[0083] Be'.

[0084] The preparation method of the natural plant stabilizer is as in Example 1.

[0085] Preparation method of nut mixed grain beverage:

[0086] Take 30g of roasted mung beans, 10g of ginseng, 10g of kudzu root and natural plant stabilizer and pour it into a high-speed refiner...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com