Beef beating and chopping machine

A technology of beef and body, applied in the direction of tenderizing meat, processing meat, softening meat by beating, etc., to achieve the effect of liberating manpower, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

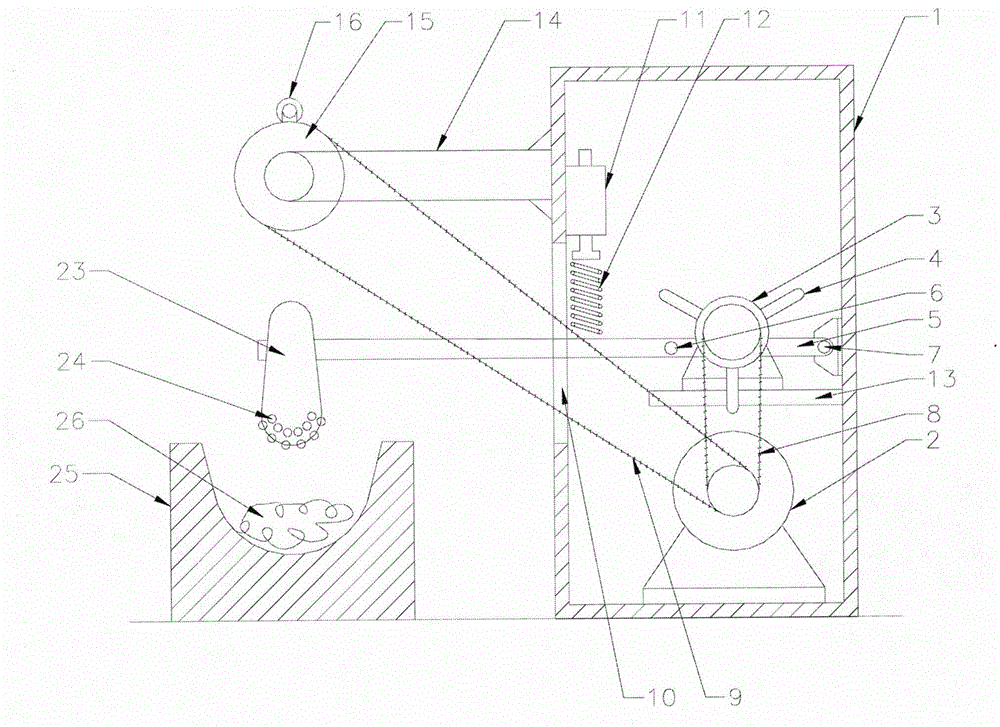

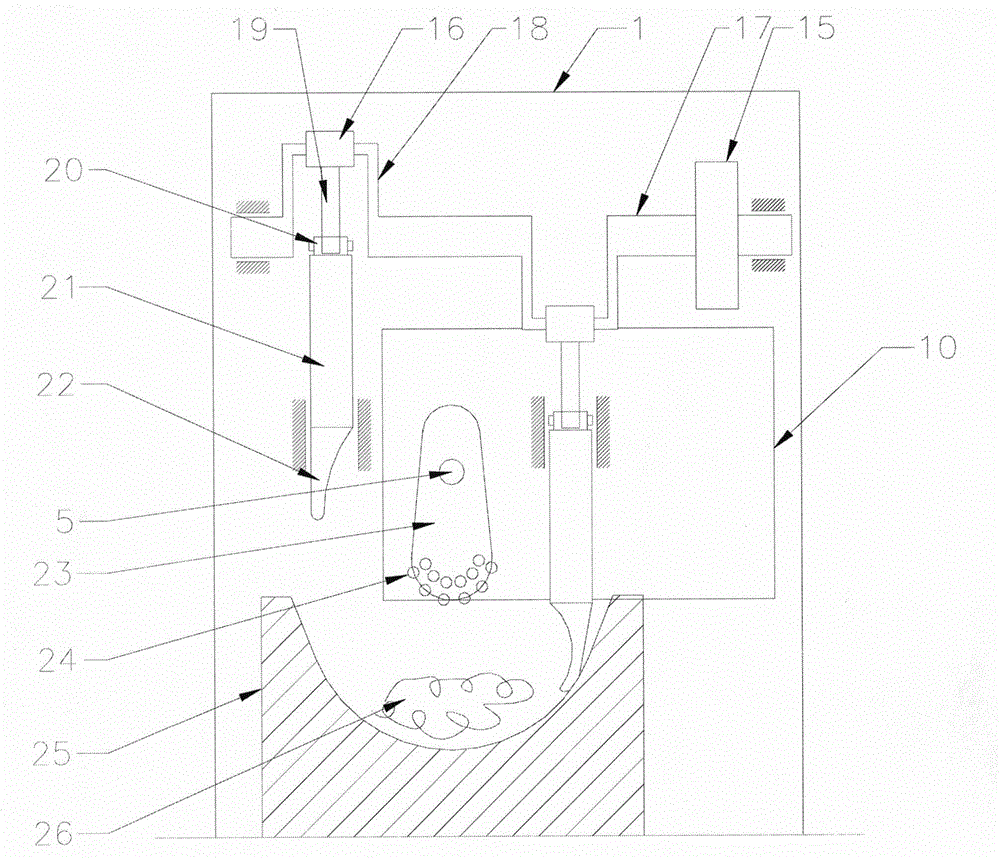

[0020] Attached below figure 1 to attach figure 2 A typical embodiment of the present invention is described:

[0021] A beef chopping machine, mainly composed of a body (1), a motor (2), a three-prong dial (3), a dial fork (4), a meat hammer connecting rod (5), a passive dial handle (6), a crankshaft Wheel (15), push the meat rod rotating shaft (16), crankshaft (17), push away the meat rod (21) in the middle, elastic tongue (22), meat hammer (23), meat stable (25) forms.

[0022] Motor (2) is installed in body (1) bottom, drives trident dial (3) by dial belt (8), drives crankshaft wheel (15) by crankshaft wheel belt (9); On the trident dial (3) has at least Three dial forks (4) arranged at equal intervals around its axis; crank (18), meat pushing rod rotating shaft (16), connecting rod part (19), connecting hinge part (20), and pushing the meat rod ( 21) form the crank-link mechanism; the elastic tongue (22) is installed in the lower end of the meat rod (21) pushed in; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com