Coaxial graphene fiber supercapacitor and manufacturing method thereof

A technology of graphene fibers and supercapacitors, which is applied in the manufacture of hybrid/electric double layer capacitors and electrodes of hybrid capacitors. It can solve the problems of bulky capacitors, bulky capacitors, and limited application range of capacitors, and achieve excellent flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

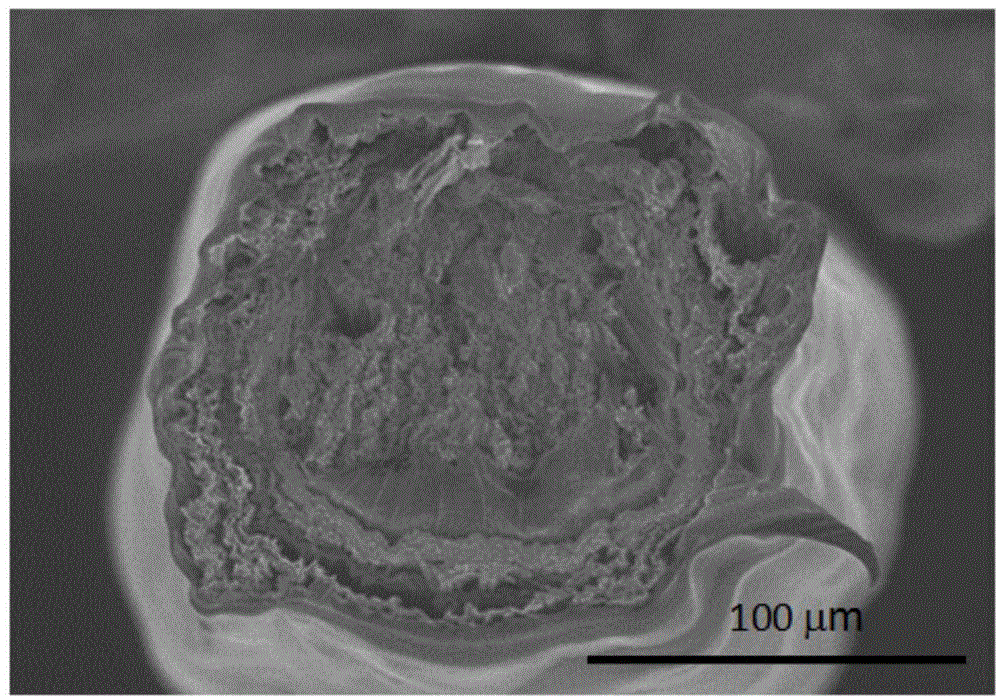

Image

Examples

preparation example Construction

[0025] The preparation method of above-mentioned coaxial graphene fiber supercapacitor comprises the following steps:

[0026] (1) Dissolving 1 part by weight of graphene oxide in 50-1000 parts by weight of deionized water, and dispersing to obtain a graphene oxide dispersion with a mass fraction of 0.1-2%;

[0027] (2) Extrude the graphene oxide dispersion liquid into the coagulation liquid with a spinning head with a diameter of 100-500 microns to obtain a gel fiber; take out the obtained gel fiber after standing still, and form a single or multiple strands Dry naturally at room temperature (20~30°C) (because drying at high temperature will reduce the effective area of the fiber for charge storage) to obtain graphene oxide fibers with a diameter in the range of 20 to 150 microns;

[0028] (3) Restore the graphene oxide fiber obtained in step 2, soak the reduced fiber in a mixed solvent obtained by mixing ethanol and water at a volume ratio of 1:1 for more than 12 hours, an...

Embodiment 1

[0039] 1) Dissolving 1 part by weight of graphene oxide raw material in 50 parts by weight of deionized water, and treating it in an ultrasonic bath to obtain a 2% mass fraction graphene oxide dispersion;

[0040] 2) Extrude the graphene oxide dispersion liquid into the coagulation liquid with a spinning head with a diameter of 100 microns, take out the obtained gel fiber after standing still, and dry naturally at room temperature in a single form to obtain graphene oxide fibers;

[0041] 4) Place the graphene oxide fiber in a 50% hydroiodic acid aqueous solution by mass fraction, reduce it at 95 degrees Celsius for 12 hours, soak it in a mixed solvent of ethanol and water (volume ratio 1:1) for more than 12 hours, take it out and put it in Dry naturally at room temperature for 24 hours to obtain a graphene fiber as the axis in the coaxial graphene fiber;

[0042] 5) Coat the graphene fiber with an aqueous solution of 20% polyvinyl alcohol by mass fraction, and dry it at room ...

Embodiment 2

[0047] 1) Dissolving 1 part by weight of graphene oxide raw material in 1000 parts by weight of deionized water and treating it in an ultrasonic bath to obtain a 0.1% mass fraction graphene oxide dispersion;

[0048] 2) Extrude the graphene oxide dispersion liquid into the coagulation liquid with a spinning head with a diameter of 500 microns, take out the obtained gel fiber after standing still, and dry naturally at room temperature in the form of multiple strands to obtain graphene oxide fibers;

[0049] 4) Place the graphene oxide fiber in a 50% aqueous solution of hydroiodic acid, reduce it at 95 degrees Celsius for 12 hours, soak it in a mixed solvent of ethanol and water for more than 12 hours, then take it out and dry it naturally at room temperature for 24 hours , to obtain a graphene fiber as the axis in the coaxial graphene fiber;

[0050] 5) Coat the graphene fiber with N,N-dimethylformamide solution with a mass fraction of 30% polyvinylidene fluoride, and dry it at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com