Liquid crystal display processing method, apparatus and equipment

A technology of liquid crystal display and processing method, applied in static indicators, instruments, etc., can solve the problems of insufficient charging of storage capacitors and affecting the image quality of liquid crystal displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

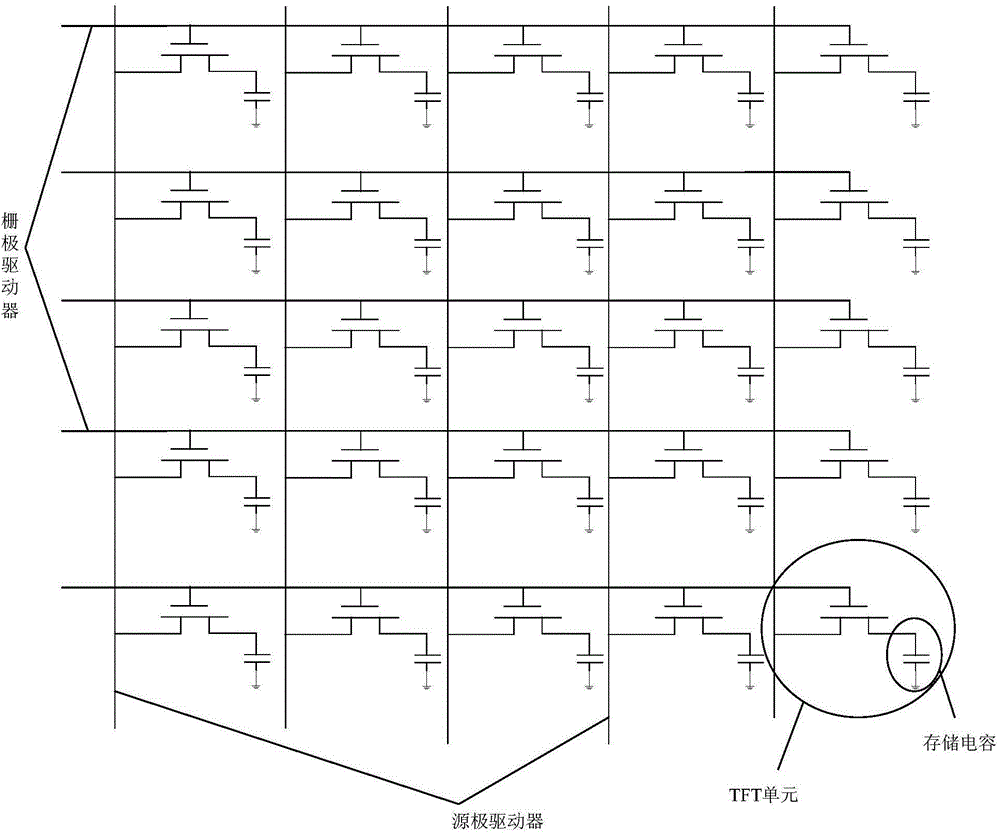

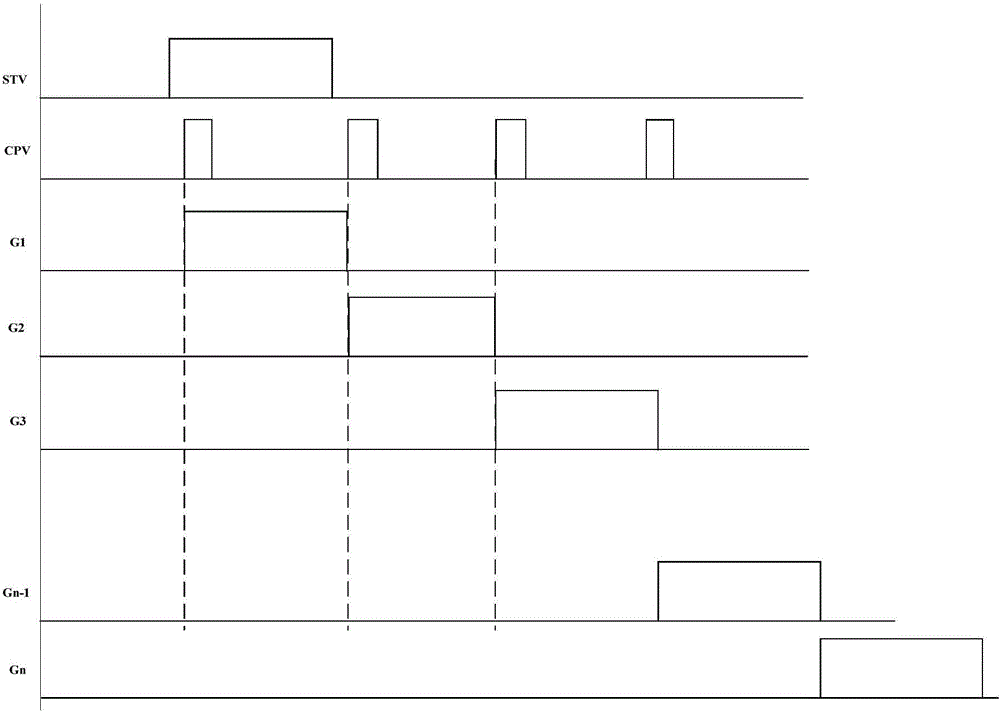

[0032] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

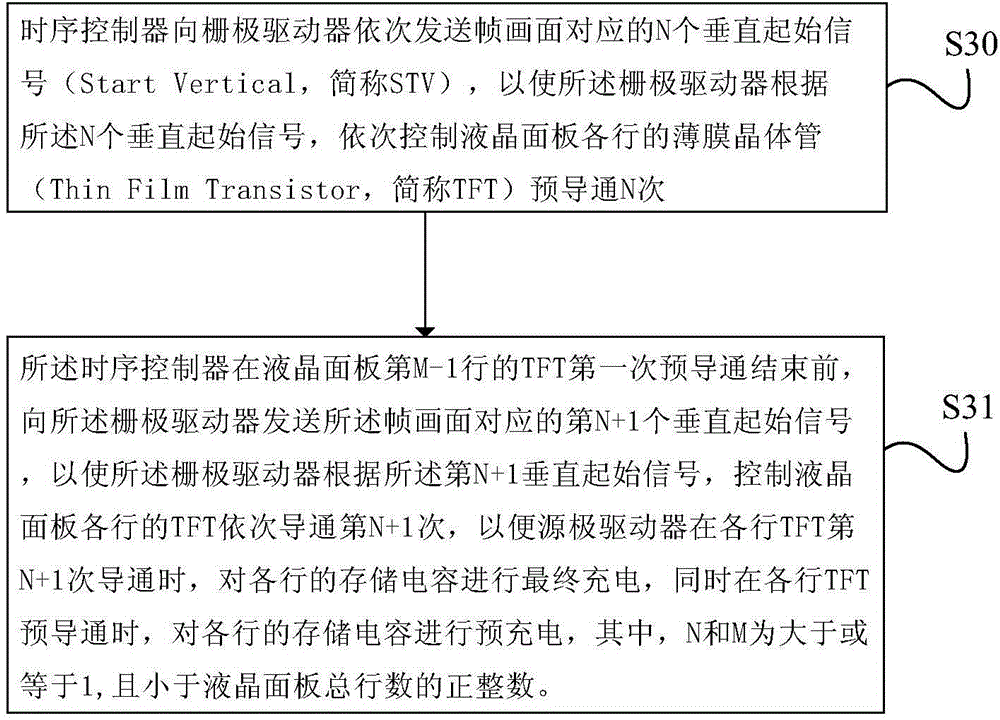

[0033] It can be seen from the analysis of the background technology that the charging time of the storage capacitors of each row of the LCD panel will be shortened with the increase of the pixels of the liquid crystal panel. It will seriously affect the image quality of the liquid crystal display, mainly because the voltage at both ends of the storage capacitor on each pixel determines the flip angle of the liquid crystal molecules. For this reason, the present invention mainly proposes a liquid crystal display processing method, device and equipment from the perspective of how to increase the voltage at both ends of the storage capacitor on each pixel.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com