Cylindrical first-order buoyancy magnetic liquid vibration absorber

A magnetic liquid and shock absorber technology, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of difficult flow of magnetic liquid, low viscous energy consumption efficiency, and fragile permanent magnets , to achieve the effect of avoiding flow difficulties, solving the problem of fragmentation, and improving the centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described with accompanying drawing as specific embodiment:

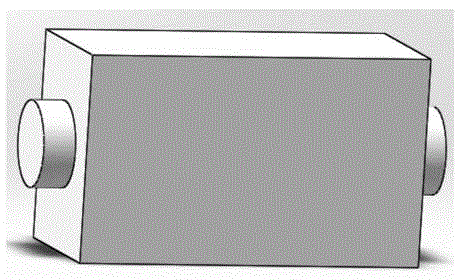

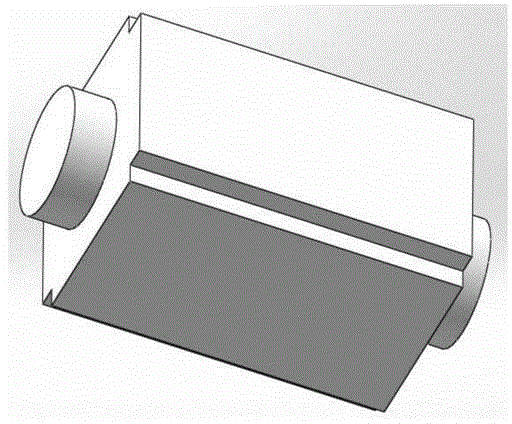

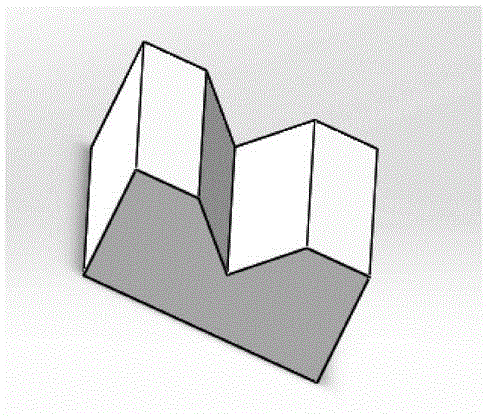

[0028] A first-order buoyancy principle magnetic liquid shock absorber with double cone angle, such as figure 1 , the damping device includes: a first limit permanent magnet 1, a housing 2, an upper V-shaped armature 3, a magnetic liquid 4, a mass 5, a second limit permanent magnet 6, a lower V-shaped armature 7, a first suspension Permanent magnet 8 , second suspended permanent magnet 9 , third suspended permanent magnet 10 and fourth suspended permanent magnet 11 .

[0029] Connections between the parts making up the device:

[0030] The housing 2 is filled with magnetic liquid 4, and the mass block 5 is loaded into the housing 2; after the housing 2 is sealed, the first limit permanent magnet 1 is fixedly installed on the left end surface of the housing 2, The second limit permanent magnet 6 is fixedly installed on the right end surface of the housing 2; the first su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com