Steel truss formwork support structure for suspended structure and installing method of steel truss formwork support structure

A technology of suspended structure and formwork support, which is applied to formwork/formwork/work frame, on-site preparation of building components, building construction, etc. Convenience and security, the effect of improving overall stability and improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

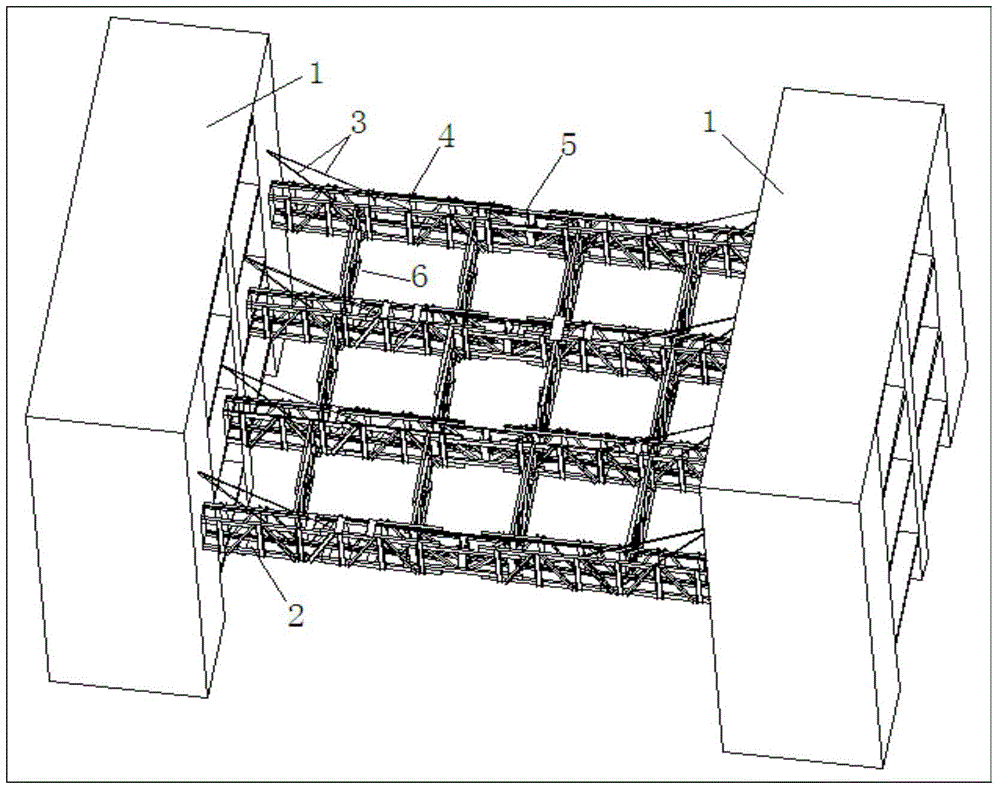

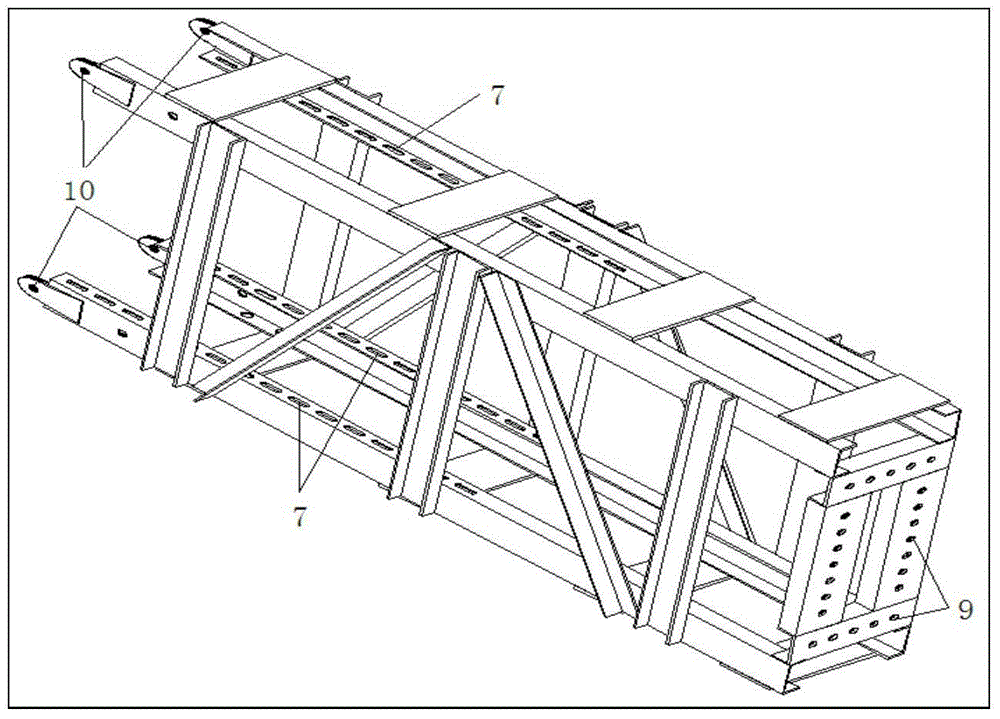

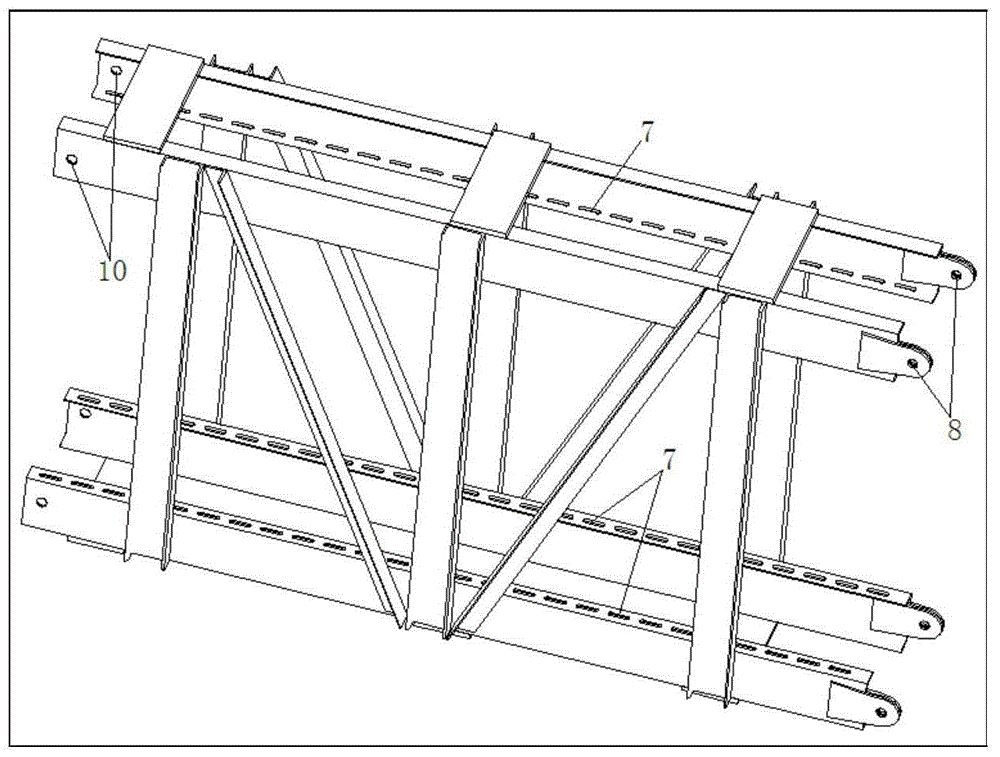

[0039] like Figure 1-8 As shown, the steel truss formwork support structure for suspended structures of the present invention, the main force-bearing member is a rectangular space truss spliced by four channel steels, the rectangular space truss includes end trusses, truss standard sections and connecting trusses, and tie rods. The end truss is used at the connection between the end of the truss and the main structure, the standard truss section is used for the extension o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com