Adhesive composition, adhesive layer and adhesive sheet

A technology of adhesive layer and composition, which is applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., and can solve problems such as poor processability, stringing, and adhesive adhesion to cutting knives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0170] 39 parts of 2-ethylhexyl methacrylate (2-EHMA), 35 parts of lauryl methacrylate (LMA), 2 parts of acrylic acid-2 - 20 parts of ethylhexyl ester (2-EHA), 5 parts of 2-hydroxyethyl acrylate (2-HEA), 1 part of acrylamide (AM) and 70 parts of ethyl acetate solvent, while introducing nitrogen, the temperature was raised to 80 ℃. Next, 0.3 parts of azobisisobutyronitrile (AIBN) was added, and polymerization reaction was performed at 80° C. for 8 hours under a nitrogen atmosphere. After completion of the reaction, it was diluted with ethyl acetate to prepare a polymer solution having a solid content concentration of 50% by mass. The obtained (meth)acrylic copolymer had a weight average molecular weight (Mw) of 380,000 and a molecular weight distribution (Mw / Mn) of 7.5.

[0171] The obtained (meth)acrylic copolymer solution (solid content concentration: 50% by mass) was mixed with 0.4 parts of HDI-based isocyanate relative to 100 parts (solid content) of the (meth)acrylic cop...

Embodiment 2~7、 comparative example 1~4

[0174] Except having used the monomer component described in Table 1, it carried out similarly to Example 1, and obtained the (meth)acrylic-type copolymer solution. Next, except having replaced the (meth)acryl-type copolymer solution as described in Table 1, it carried out similarly to Example 1, and obtained the adhesive sheet which has the adhesive composition and the adhesive layer of thickness 50 micrometers.

[0175] [Table 1]

[0176]

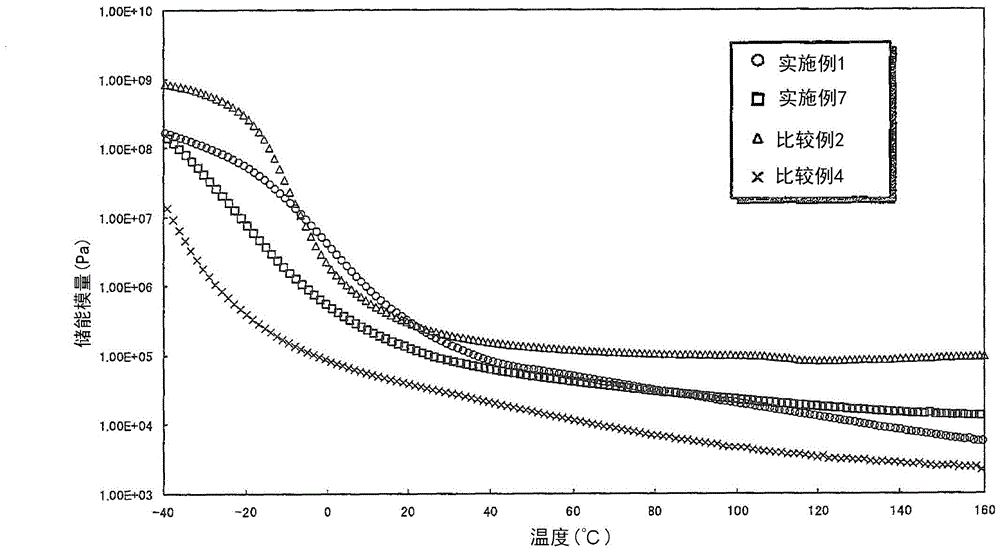

[0177] As shown in Table 1, if the storage modulus (25°C) of the adhesive layer is 0.8×10 5 Above Pa, and the storage modulus (80°C) is 5.0×10 4 Pa or less, the step followability and the cutting property are excellent. On the other hand, as shown in Comparative Examples 1 and 2, if the storage modulus (80°C) of the adhesive layer exceeds 5.0×10 4 Pa, the step followability is poor. As shown in Comparative Examples 3 and 4, if the storage modulus (25° C.) of the adhesive layer is less than 0.8×10 5 Pa, the cutting property is poor....

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage modulus | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com