Construction waste reclaimed brick powder-containing spray construction heat insulation mortar

A technology of construction waste and thermal insulation mortar, which is applied in the direction of sustainable waste treatment, solid waste management, and climate sustainability. It can solve the problems that thermal insulation mortar cannot be mechanized, the overall bulk density of mixed materials increases, and cannot meet the use requirements. Achieve the effects of easy mechanized spraying construction, improving air content and fluidity, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

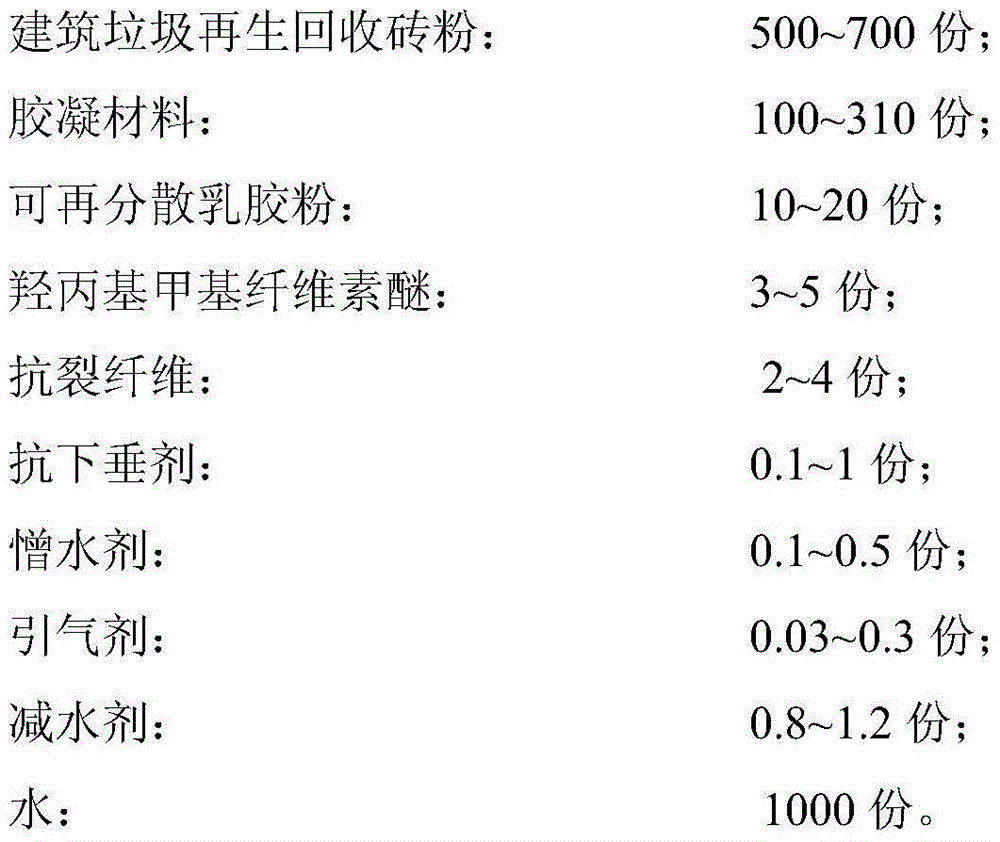

Embodiment 1

[0048] (1) Weigh each component according to the proportions in Table 1, firstly mix the construction waste recycled brick powder (the mixture of ordinary fired brick and aerated brick, the weight ratio is 1:1), and the cementitious material in the mixer , and then add redispersible latex powder ethylene / vinyl acetate copolymer, hydroxypropyl methylcellulose ether, anti-cracking fiber (wood fiber and polypropylene fiber, weight ratio 1:1), anti-sag agent Xanthan gum, water-repellent agent, air-entraining agent sodium dodecylbenzene sulfonate, and water-reducing agent high-efficiency polycarboxylate-based water-reducer are fully mixed and stirred evenly, and finally weighed water is added and stirred for 5 minutes to form a slurry. The waterproof, environment-friendly, A-level flame-retardant and heat-retaining mortar of the present invention is obtained.

[0049] At this time, the mixture has a viscosity suitable for mechanical spraying, which can produce good adhesion to the ...

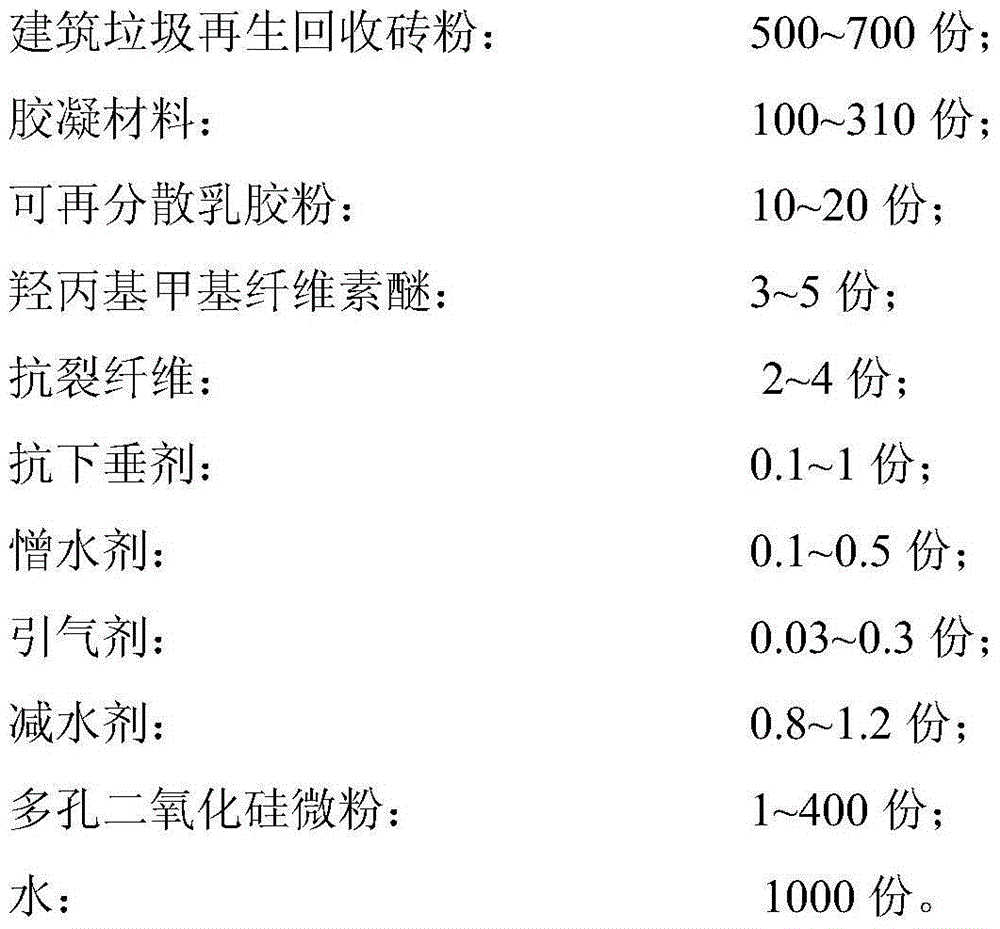

Embodiment 2

[0055] (1) Weigh each component according to the proportions in Table 1, firstly mix the construction waste recycled brick powder (the mixture of ordinary fired brick and aerated brick, the weight ratio is 1:1), and the cementitious material in the mixer , and then add redispersible latex powder ethylene / vinyl acetate copolymer, hydroxypropyl methylcellulose ether, anti-cracking fiber (wood fiber and polypropylene fiber, weight ratio 1:1), anti-sag agent Xanthan gum, water-repellent agent, air-entraining agent sodium dodecylbenzene sulfonate, water-reducing agent high-efficiency polycarboxylate-based water-reducing agent, and porous silica micropowder are fully mixed and stirred evenly, and finally weighed water is added, Stir for 5 minutes to form a slurry to obtain the waterproof, environmental protection, Class A flame-retardant and heat-retaining mortar of the present invention.

[0056] At this time, the mixture has a viscosity suitable for mechanical spraying, which can ...

Embodiment 3

[0062] (1) Weigh each component according to the proportions in Table 1, firstly mix the construction waste recycled brick powder (the mixture of ordinary fired brick and aerated brick, the weight ratio is 1:1), and the cementitious material in the mixer , and then add redispersible latex powder ethylene / vinyl acetate copolymer, hydroxypropyl methylcellulose ether, anti-cracking fiber (wood fiber and polypropylene fiber, weight ratio 1:1), anti-sag agent Xanthan gum, water-repellent agent, air-entraining agent sodium dodecylbenzenesulfonate, water-reducing agent high-efficiency polycarboxylate-based water-reducing agent, and porous silica micropowder are fully mixed and stirred evenly, and finally weighed water is added, Stir for 5 minutes to form a slurry to obtain the waterproof, environmental protection, Class A flame-retardant and heat-retaining mortar of the present invention.

[0063] At this time, the mixture has a viscosity suitable for mechanical spraying, which can p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com