Cellulose-based template based spindle-shaped nano-titanium dioxide and preparation method thereof

A nano-titanium dioxide, cellulose-based technology, applied in the direction of titanium dioxide, nanotechnology for materials and surface science, titanium oxide/hydroxide, etc., can solve the problems of insufficient purity and mixed anatase, and achieve good adsorption effect , The preparation method is simple and easy to operate, and the raw materials are green.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Disperse commercially available cellulose fibers (1g) in 150ml of water, then slowly add concentrated sulfuric acid (2ml) dropwise while stirring;

[0039] 2) Add titanyl sulfate (TiOSO) dropwise in the above fiber dispersion 4 ·H 2 SO 4 ·H 2 O) solution (1.1 g), while continuing to stir;

[0040] 3) Heating in an oil bath at 60°C for 7 hours while stirring;

[0041] 4) The reaction is completed, cooled, then vacuum filtered, and the fibrous filter cake after filtration is rinsed with deionized water several times, dried to obtain cellulose-based nano TiO 2 .

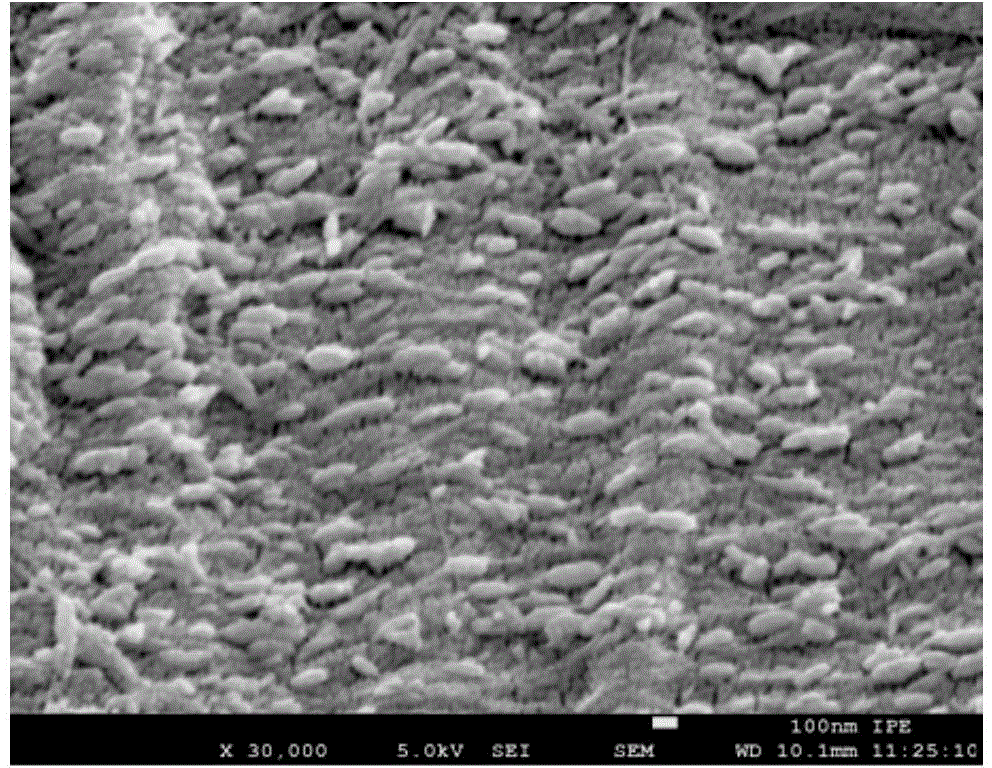

[0042] figure 1 Cellulose-based nano-TiO prepared for this example 2 SEM photo, as can be seen from the photo: TiO 2 The nanoparticles are uniformly dispersed on the surface of the cellulose base and are in the shape of spindles. These spindle-shaped crystals are about 180nm long and 50nm wide.

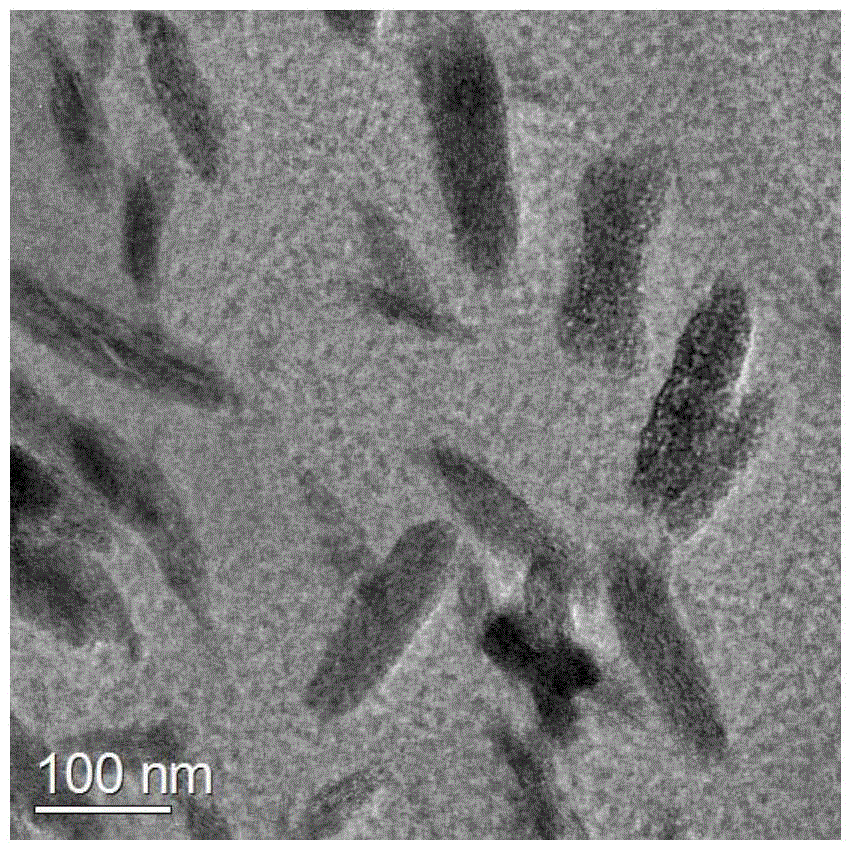

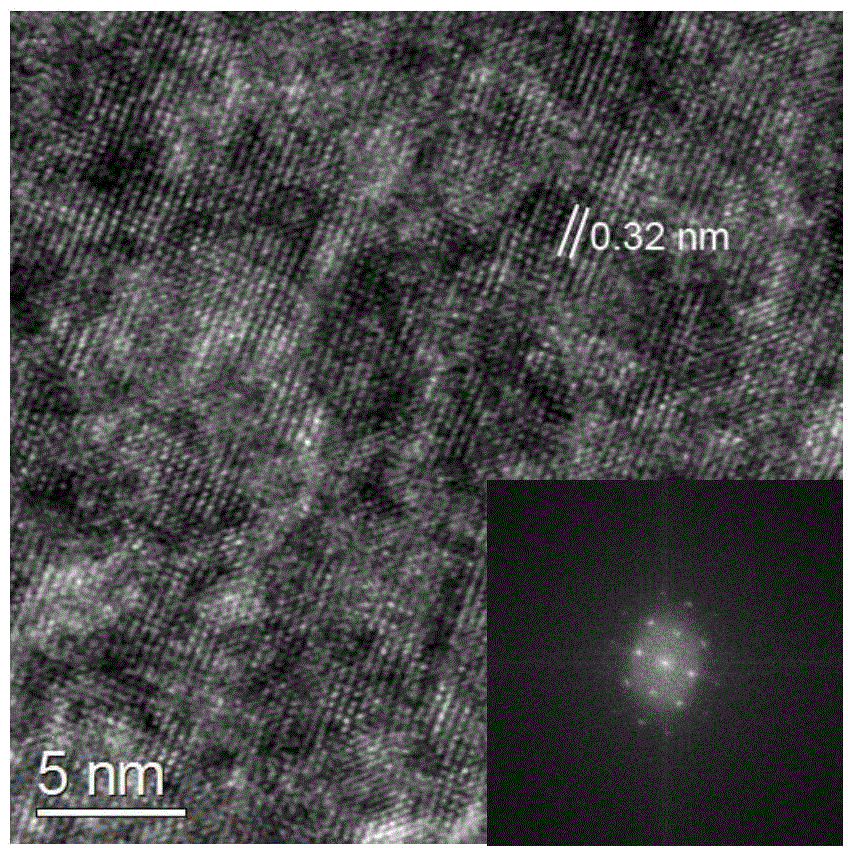

[0043] figure 2 Cellulose-based nano-TiO prepared for this example 2 The TEM pictures further confirmed...

Embodiment 2

[0048] 1) Disperse commercially available cellulose fibers (1g) in 200ml of water, then slowly add concentrated sulfuric acid (3ml) dropwise while stirring;

[0049] 2) Add titanyl sulfate solution (0.8 g) dropwise to the fiber dispersion, while continuing to stir;

[0050] 3) Heating in an oil bath at 70°C for 5 hours while stirring;

[0051] 4) The reaction is completed, cooled, then vacuum filtered, and the fibrous filter cake after filtration is rinsed with deionized water several times, dried to obtain cellulose-based nano TiO 2 .

Embodiment 3

[0053] 1) Soak commercially available filter paper (1g) in 100ml of water, then slowly add sulfuric acid (1ml) dropwise while stirring slowly;

[0054] 2) Add titanyl sulfate solution (0.5 g) drop by drop to the above solution while continuing to stir;

[0055] 3) Heating in an oil bath at 80°C for 6 hours while stirring;

[0056] 4) The reaction is completed, cooled, then vacuum filtered, and the reacted filter paper is rinsed with deionized water several times, dried to obtain cellulose-based nano-TiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com